Oyster activated peptide-zinc chelate and preparation method and application thereof

A chelate and active peptide technology, applied in the field of oyster active peptide zinc chelate and its preparation, can solve problems such as limited physiological functions, and achieve the effects of improving absorption and utilization, high bioavailability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

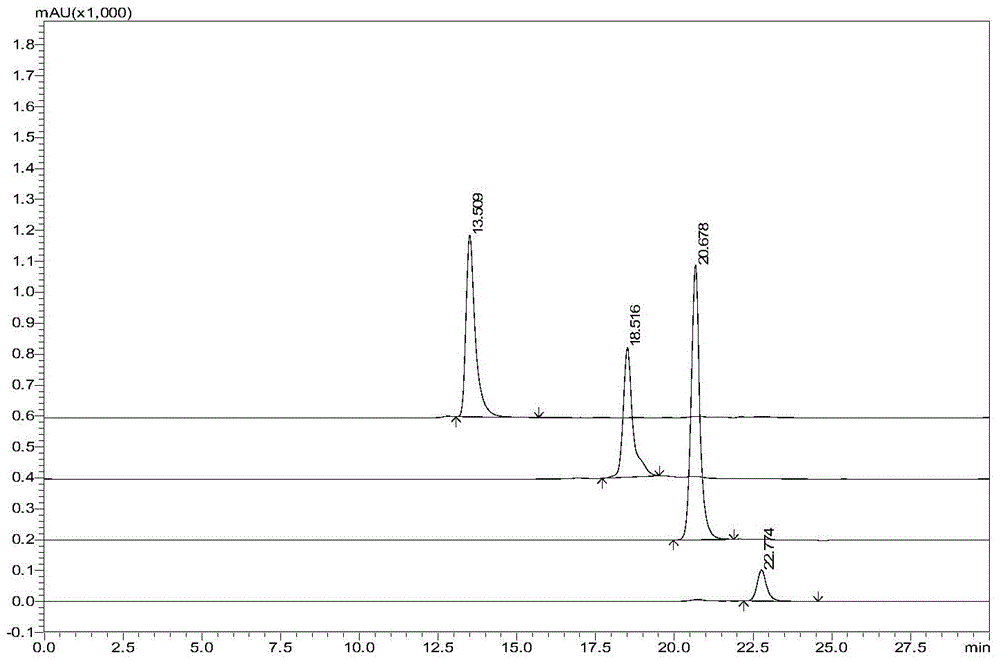

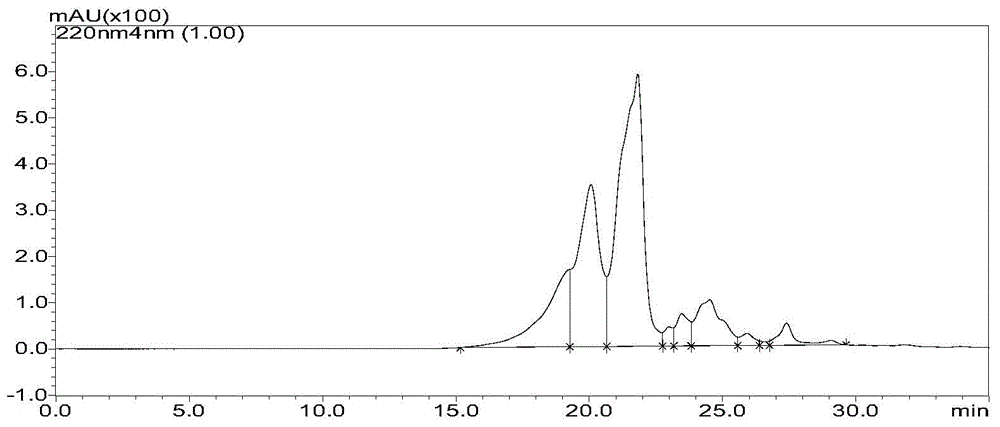

Image

Examples

Embodiment 1

[0039] 1. Preparation and quality inspection of oyster active peptide

[0040] 1.1 Preparation of oyster active peptides

[0041] After crushing 600kg of shelled oysters, add 600kg of water, put them into a colloid mill and grind them into oyster slurry, then add food-grade citric acid to the oyster slurry to adjust the pH value to about 3, stir at 20°C for 1 hour, and centrifuge Remove the supernatant to obtain the oyster slag.

[0042] Mix and stir the above oyster dregs with water at a ratio of 1:1 to water and dregs, adjust the pH to 7-9, heat to 60°C, add 10 U of flavor protease and 10 U of papain per gram of oyster dregs for enzymatic After 6 hours of enzymatic hydrolysis, heat the enzymatic solution to 100°C for about 15 minutes to inactivate the enzyme.

[0043] Use a tubular centrifuge at a speed of 14000r / min to centrifuge the enzymolysis solution after deactivating the enzyme, collect the centrifuged supernatant, and perform membrane filtration with an ultrafiltra...

Embodiment 2

[0093] 1. Preparation and quality inspection of oyster active peptide

[0094] After crushing 600kg of shelled oysters, add 1800kg of water and grind them into oyster slurry, then add food-grade citric acid to the oyster slurry to adjust the pH value to about 5, stir at 30°C for 3 hours, and centrifuge to remove the supernatant , to obtain oyster slag.

[0095] Mix and stir the above oyster dregs with water at a ratio of 3:1 to water and dregs, adjust the pH value to 7-9, heat to 45°C, add 50 U of flavor protease and 50 U of papain per gram of oyster dregs for enzymatic After 4 hours of enzymatic hydrolysis, the enzyme was inactivated.

[0096] Centrifuge the enzymatic hydrolysis solution after deactivating the above enzyme at a speed of 14000r / min, collect the centrifuged supernatant, and perform membrane filtration with an ultrafiltration device with a pore size of 0.06μm, under the conditions of pressure 0.3MPa and temperature 55°C. Oyster Active Peptide Permeate.

[009...

Embodiment 3

[0104] 1. Preparation and quality inspection of oyster active peptide

[0105] After crushing 600kg of shelled oysters, add 3000kg of water and grind them into oyster slurry, then add food-grade citric acid to the oyster slurry to adjust the pH value to about 7, stir at 50°C for 5 hours, and centrifuge to remove the supernatant , to obtain oyster slag.

[0106] Mix and stir the above oyster dregs with water at a ratio of 5:1 to water and dregs, adjust the pH value to 7-9, heat to 60°C, add 100 U of flavor protease and 100 U of papain per gram of oyster dregs for enzymatic After 2 hours of enzymatic hydrolysis, the enzyme was inactivated.

[0107] Centrifuge the enzymatic hydrolysis solution after deactivating the above enzyme at a speed of 16000r / min, collect the centrifuged supernatant, and perform membrane filtration with an ultrafiltration device with a pore size of 0.1μm, under the conditions of pressure 0.4MPa and temperature 60°C. Oyster Active Peptide Permeate.

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com