Brake ring

A technology of brake rings and brake parts, which is applied in the field of brake rings, can solve the problems of low braking effect, insufficiently filled products, and air trapped, so as to achieve effective performance, improve processing reliability, and reduce reprocessing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

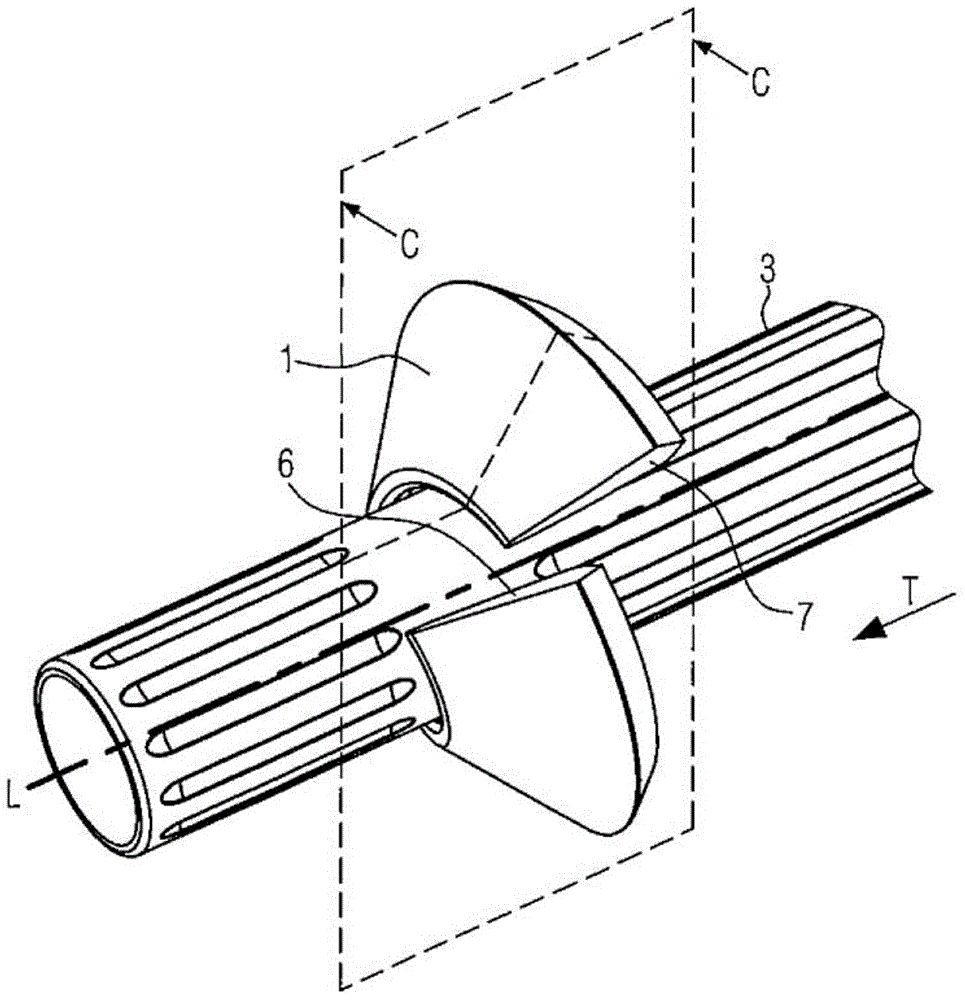

[0084] figure 1 A first embodiment of the brake ring 1 according to the invention is shown in perspective. The reference numeral 3 designates a filling tube via which the pasty substance is conveyed into the casing 11 in a known manner, wherein the casing, not shown here, is pulled over the filling tube 3 during operation. The pasty substance is passed through in a generally known manner Figure 14 The hopper 13 and feeding mechanism 17 shown in Fig. 2 fill the filling tube 3 intermittently or continuously, which will not be shown in more detail here.

[0085] In mechanical sausage production, the casing 11 is first placed on the stuffing tube 3 or covers the free end 3a of the stuffing tube 3 . Next, the casing brake 10 (see image 3 ) is located on the filling pipe 3. The casing brake 10 can be positioned at different positions in the conveying direction T of the casing (here, for the sake of simplicity, the casing is not shown, see Figure 13 ).

[0086] According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com