A patch head of a placement machine

A chip mounter and chip mounter technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of not being able to guarantee the consistency and stability of the amplitude change, and achieve the effect of simple structure and guaranteed consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

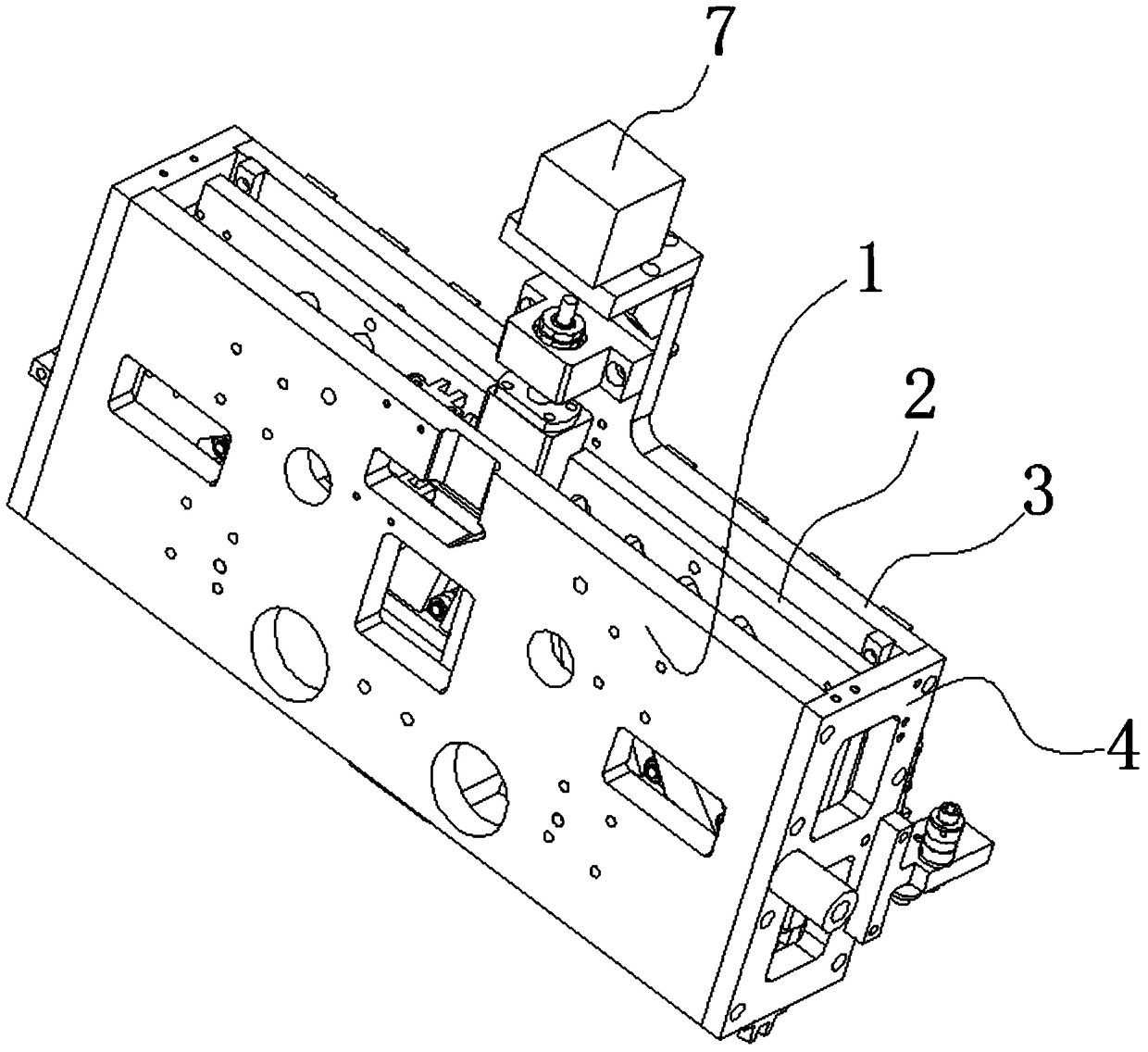

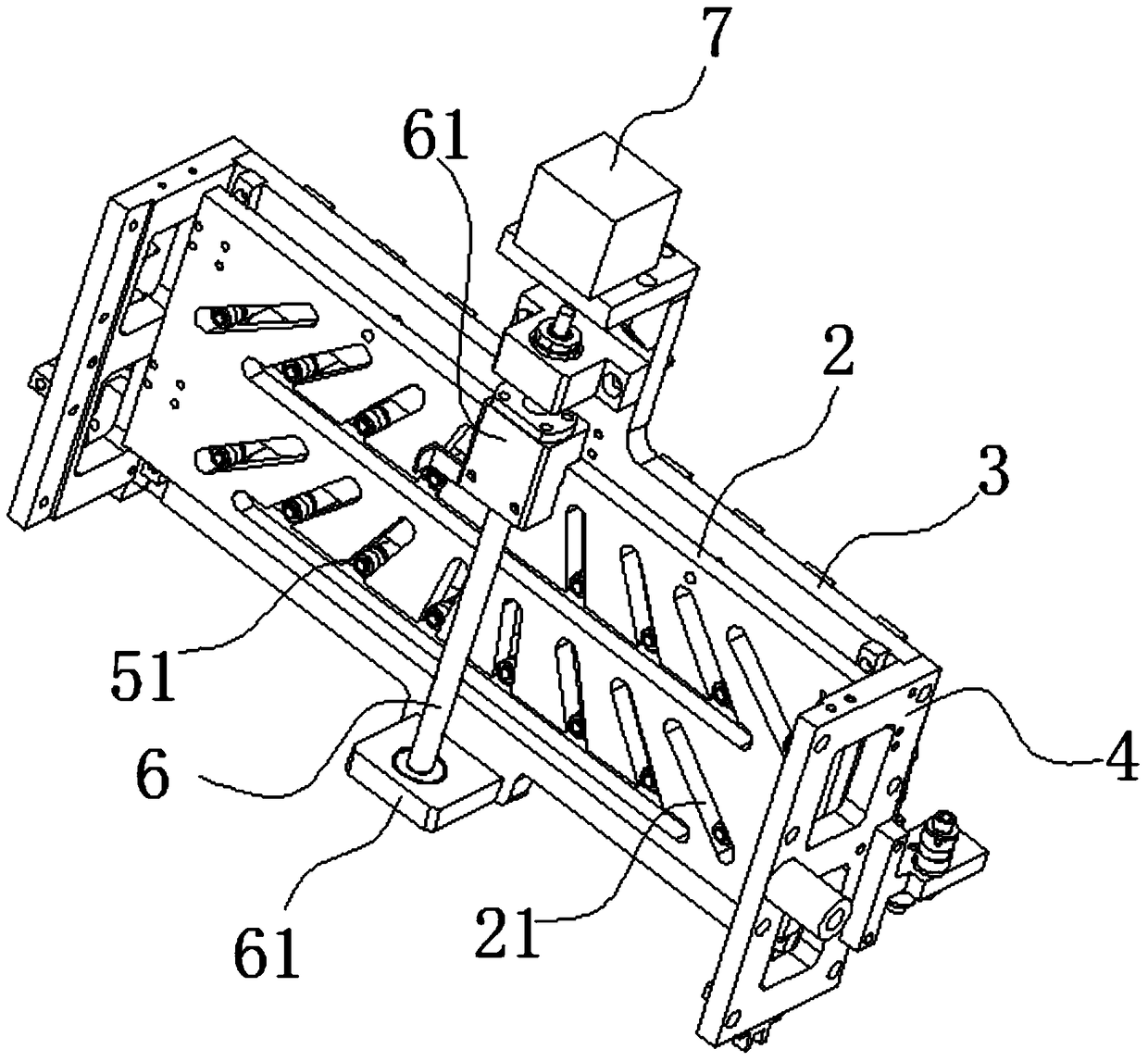

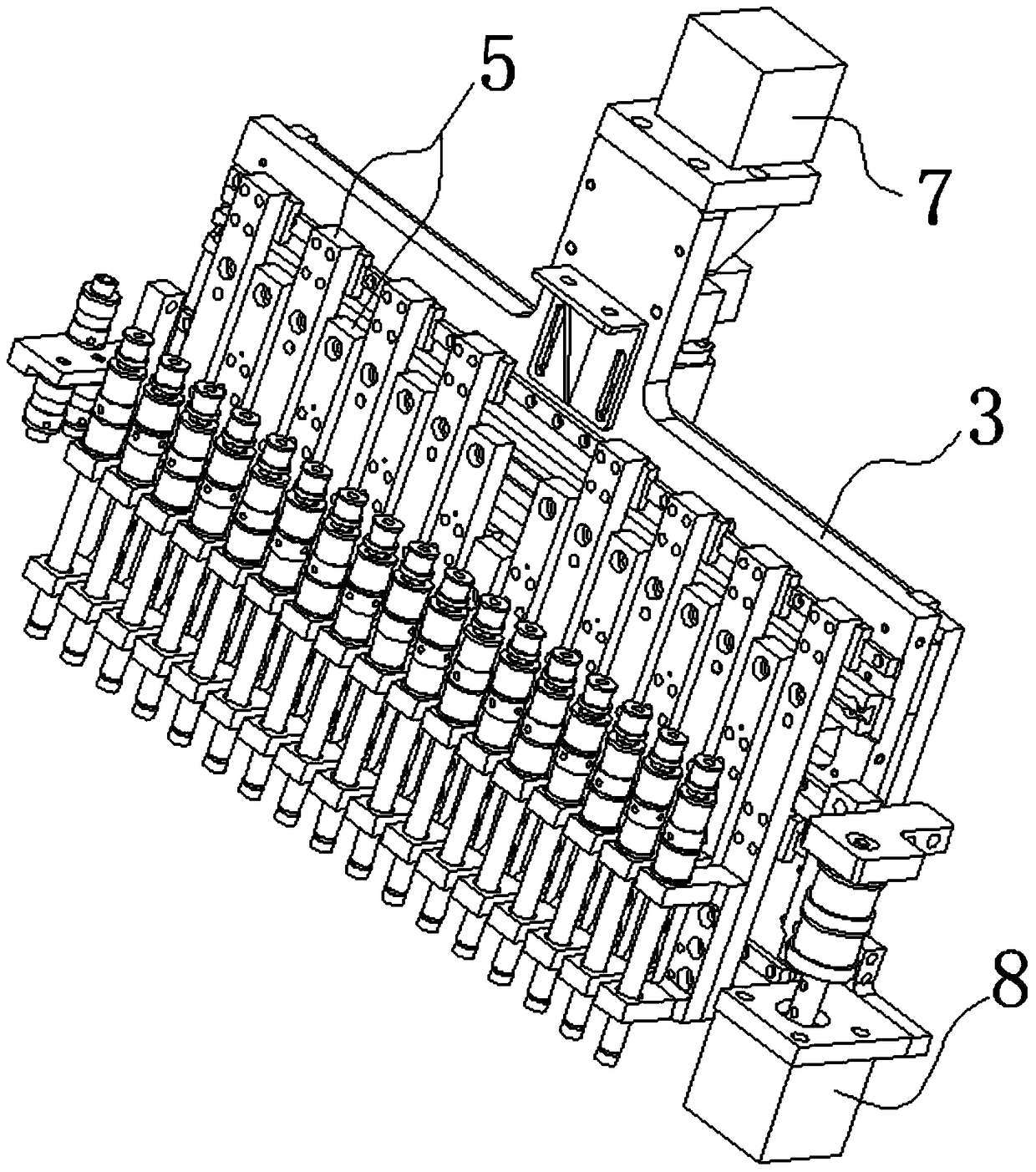

[0039] See Figure 1 to Figure 4 As shown, the placement head of the placement machine includes a mounting assembly and a plurality of nozzle assemblies 5, and the plurality of nozzle assemblies 5 are installed side by side on the mounting assembly laterally. Among them, the mounting assembly includes a guide plate 2 and a mounting plate 3.

[0040] The guide plate 2 and the mounting plate 3 are arranged in layers. The guide plate 2 is provided with a plurality of guide holes 21, the guide holes 21 include the inner wall of the holes, and the guide holes 21 are arranged obliquely.

[0041] Furthermore, the guide plate 2 has an axisymmetric structure in the lateral direction, and the plurality of guide holes 21 on the guide plate 2 are arranged obliquely, and the plurality of obliquely arranged guide holes 21 are distributed axisymmetrically about the symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com