Heat radiation system of electrical cabinets in power distribution room

A heat dissipation system and electrical cabinet technology, applied in the electrical field, can solve problems such as cost-effectiveness, high energy consumption, and easy damage to components, and achieve good convection effects, good cooling efficiency, and the effect of not being easy to rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

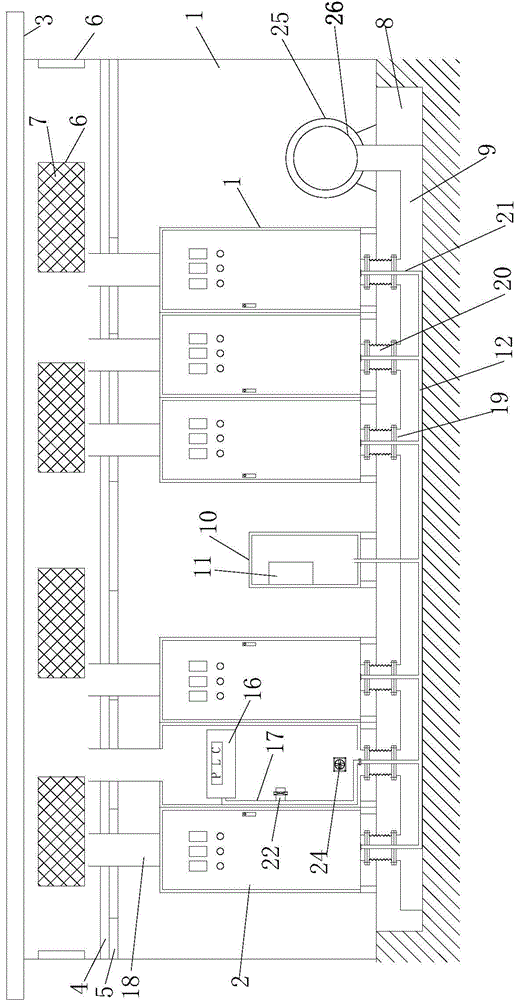

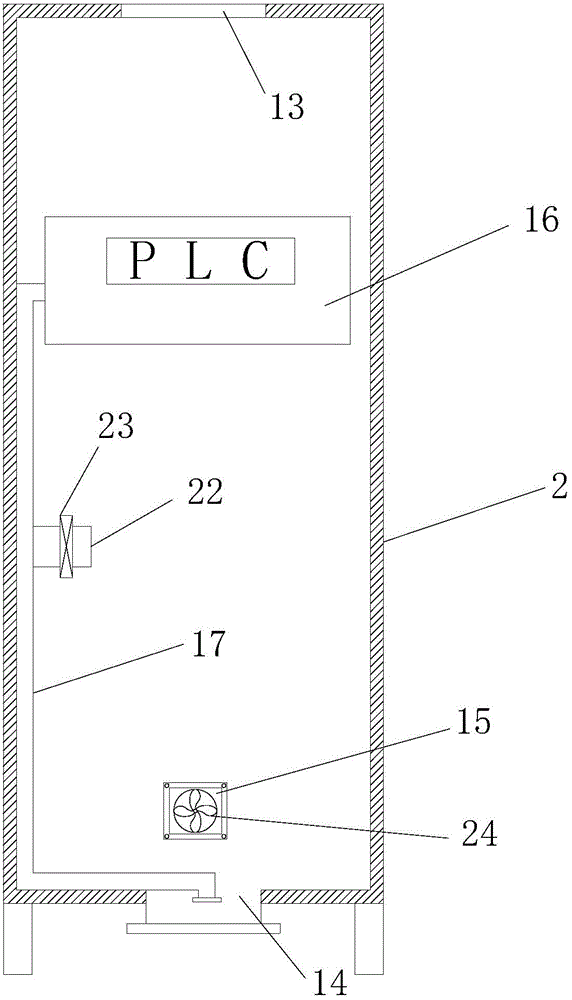

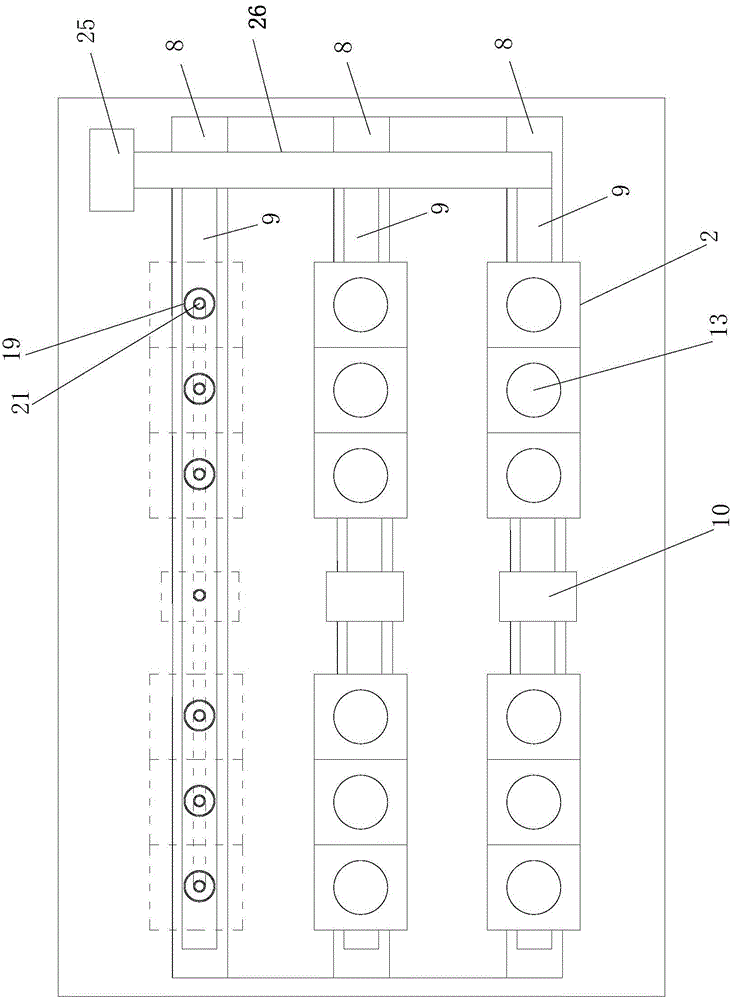

[0032] like figure 1 , 2As shown in . , the upper part of the power distribution room 1 is provided with a keel 4, and the lower part of the keel 4 is connected with a ceiling board 5, and all the ceiling boards 5 divide the power distribution room 1 into upper and lower spaces, and the power distribution room 1 is located on the ceiling board 5 Ventilation windows 6 are opened on all four sides of the upper part, and insect-proof nets 7 are arranged on the ventilation windows 6. A plurality of parallel slots 8 are opened on the ground of the power distribution room 1, and each slot 8 is provided with a ventilation window. Road 9; an air-conditioning cabinet 10 is provided at the upper center of each slot 8, and an air-conditioning 11 is provided in the air-conditioning cabinet 10, and electrical cabinets 2 arranged in a line are arranged on both sides of the air-conditioning cabinet 10, The width of the groove 8 is smaller than the air-conditioning cabinet 10 and the electr...

Embodiment 2

[0036] like Figure 4 , 5 As shown, the heat dissipation system of the electrical cabinet in the power distribution room described in this embodiment is different from Embodiment 1 in that the upper part of the exhaust pipe 18 is fixed on the keel 4, and the middle part of the exhaust pipe 18 is provided with A section of telescopic pipe 28 is provided with a flange 27 at the bottom of the exhaust pipe 18, and the flange 27 is connected with the electrical cabinet 2. The telescopic pipe 28 can be a plastic corrugated pipe, so that the exhaust pipe 18 can be stretched, and it is convenient to connect with the electrical cabinet 2 during installation.

Embodiment 3

[0038] like Image 6 As shown, the heat dissipation system of the electrical cabinet in the power distribution room described in this embodiment is based on Embodiment 1. A temperature sensor 29 is provided in each electrical cabinet 2, and a temperature sensor 29 is provided in one of the air-conditioning cabinets 10. The total controller 30, the temperature sensor 29 in each electric cabinet 2 measures the temperature tt in the electric cabinet 2 and inputs it to the total controller 30, and the total controller 30 controls the fan 25 and each electric cabinet The air outlet valve 23 and the fan 24 in 2 work and the control method is as follows:

[0039] i. the total controller 30 controls the blower fan 25 to work once every other period of time and lasts T; T can generally be selected as 3 to 5 minutes, and the interval time can be selected as 1-2 hours; the effect of this step is that the blower fan 25 can work regularly, remove the heat in all electrical cabinets 2 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com