Packaging structure for chip nixie tubes used for display screen

A packaging structure and digital tube technology, applied in the field of LED digital display, can solve the problems of increasing product production process, affecting product performance, limiting product volume, etc., to improve heat dissipation and waterproof performance, good stability in use, and easy packaging and storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

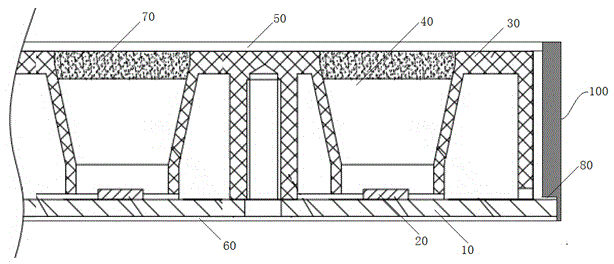

[0028] figure 1 It shows a packaging structure of a display screen with a chip digital tube in a preferred embodiment of the present invention, while referring to figure 2 , the packaging structure of the display screen with SMD digital tubes includes 16 pieces with an area of 4cm 2 A cuboid digital tube package structure unit 1, the multiple digital tube package structure units 1 are arranged in a rectangular array and two adjacent said digital tube package structure units 1 are detachably connected, each said digital tube package The structural unit 1 includes a PCB board 10, a plurality of patch LEDs 20 mounted on the PCB board 10, and a square box 100 for accommodating the PCB board, and the square box 100 includes two sets of side walls parallel to each other , one side wall of each set of side walls is provided with a buckle (not shown), and the other side wall of the set of side walls is provided with a buckle groove (not shown) adapted to the buckle , the buc...

Embodiment 2

[0036] This embodiment provides a packaging structure of a chip digital tube for a display screen, and its structure is consistent with that of Embodiment 1. Particularly preferably, the gap between the nixie tube packaging structural units is filled with an interunit layer, and its raw materials include 70 parts of polyvinyl chloride, 0.3 parts of p-dichlorobenzene, 2 parts of ethylene glycol, 0.9 parts of trimellitic acid tris octyl ester, 2 parts of ferrous sulfate; its preparation method is to add dichlorobenzene in the ethylene glycol and trizinc trimellitic acid, the mixture is heated to 129 °C under three atm, irradiated with 280nm ultraviolet light and Keep it for 10 minutes; heat the above-mentioned polyvinyl chloride to 160°C at 1 atm, add the ferrous sulfate and the mixture and keep it warm for 15 minutes, then inject it into the gap of the digital tube packaging structural unit, and obtain the inter-unit layer after curing .

Embodiment 3

[0038] This embodiment provides a packaging structure of a chip digital tube for a display screen, and its structure is consistent with that of Embodiment 1. Particularly preferably, the gap between the nixie tube packaging structural units is filled with an interunit layer, and its raw materials include 81 parts of polyvinyl chloride, 0.11 parts of p-dichlorobenzene, 4.5 parts of ethylene glycol, 0.7 parts of trimellitic acid tris Octyl esters, 6 parts of ferrous sulfate; the preparation method is to add dichlorobenzene to the ethylene glycol and trimellitic acid trizinc ester, heat the mixture to 118°C at three atm, and use continuous wavelength of 280-310nm Irradiate with ultraviolet light and keep it for 10 minutes; heat the above-mentioned polyvinyl chloride to 153°C at 1 atm, add the ferrous sulfate and the mixture and keep it warm for 15 minutes, inject it into the gap of the digital tube packaging structural unit, and obtain the described interunit layer.

[0039] Fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com