Photosensitive plane target

A photosensitive surface and photosensitive technology, applied in the field of photosensitive surface target

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

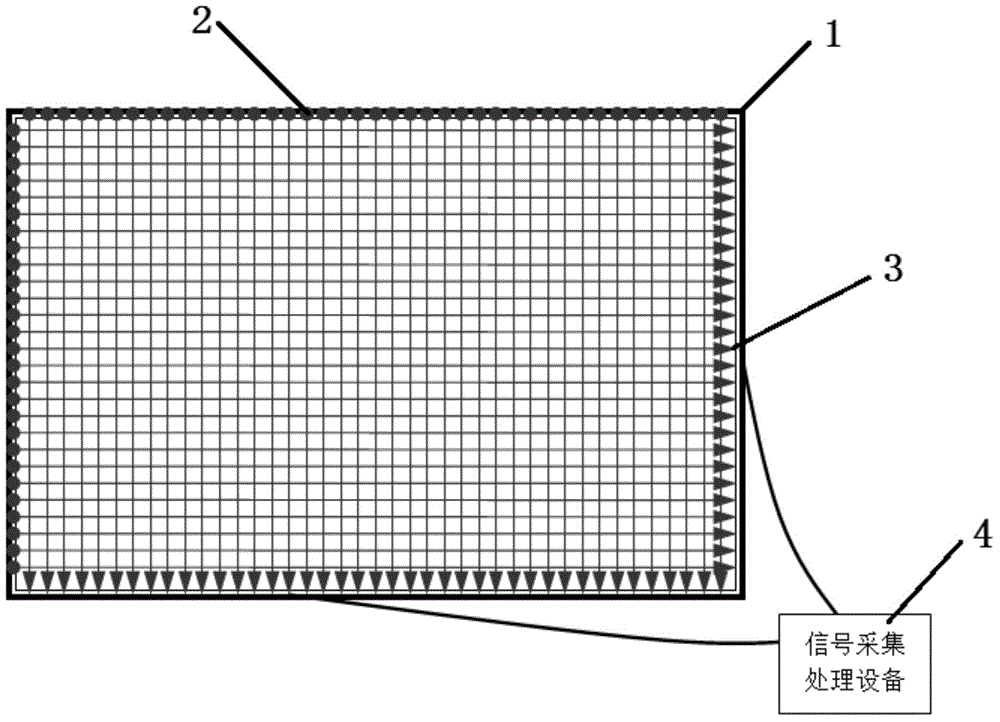

[0030] Such as figure 1 As shown, a photosensitive surface target described in this embodiment includes an outer frame 1, a laser emitting and receiving array, and a signal acquisition and processing device 4, wherein the laser emitting and receiving arrays are at least two groups, and two groups of lasers The emitting and receiving arrays are arranged crosswise on the outer frame, and the laser receiving end 3 of each group of the laser emitting and receiving arrays is connected to the signal acquisition and processing device 4 .

[0031] The laser emitting and receiving arrays are located on the same plane.

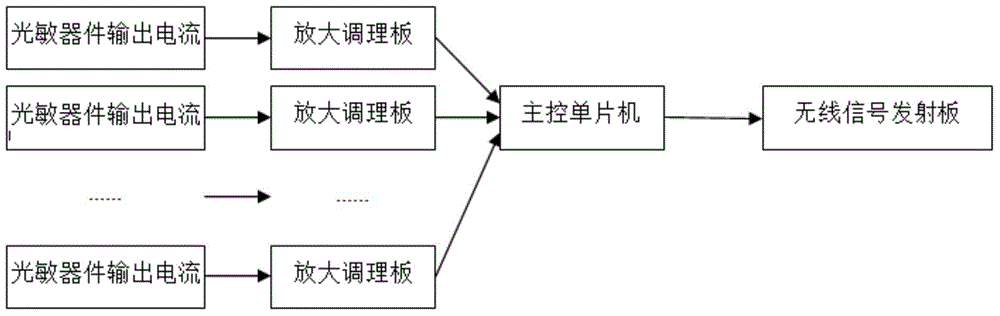

[0032] The laser receiving end 3 is a photosensitive element composed of several laser receiving elements arranged side by side. Each laser receiving element can generate a photosensitive signal with a high level output after receiving laser beam irradiation, and output Low level, the output signal of each laser receiving element is sent to the signal acquisition and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com