Spherical plain bearing

A joint bearing and axis technology, applied in the directions of bearings, bearing components, shafts and bearings, can solve the problems of increasing the installation sleeve steps, increase the cost, etc., and achieve the effect of eliminating the installation sleeve, easy deformation, and reduced position stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Such as Figure 4 and Figure 5 As shown, the joint bearing of the first embodiment of the present invention includes:

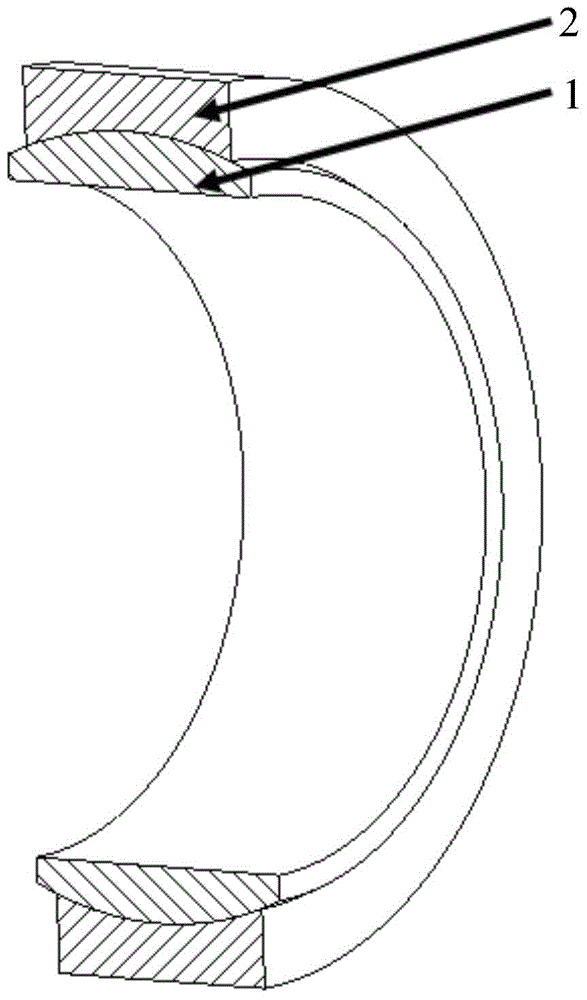

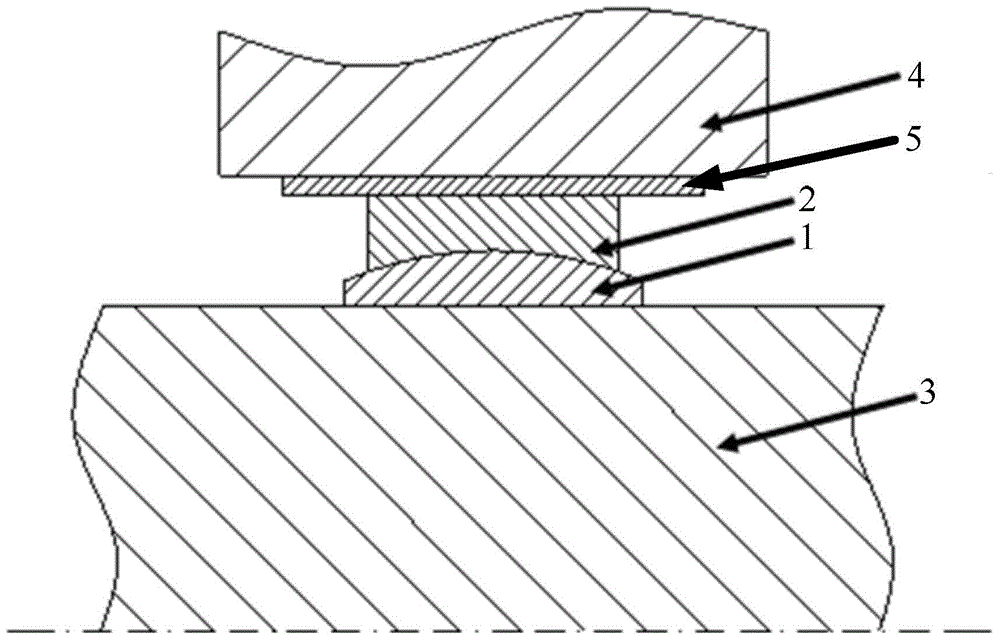

[0032] an inner ring 10 with an outer spherical surface;

[0033] The outer ring 20 is sleeved on the inner ring 10. The outer ring 20 has an inner spherical surface S1 slidingly fitted with the outer spherical surface of the inner ring 10 and annular end surfaces S2 located on both sides of the inner spherical surface S1 in the axial direction. The annular end surface S2 is provided with a ring An annular groove 200 on the axis of the outer ring 20 .

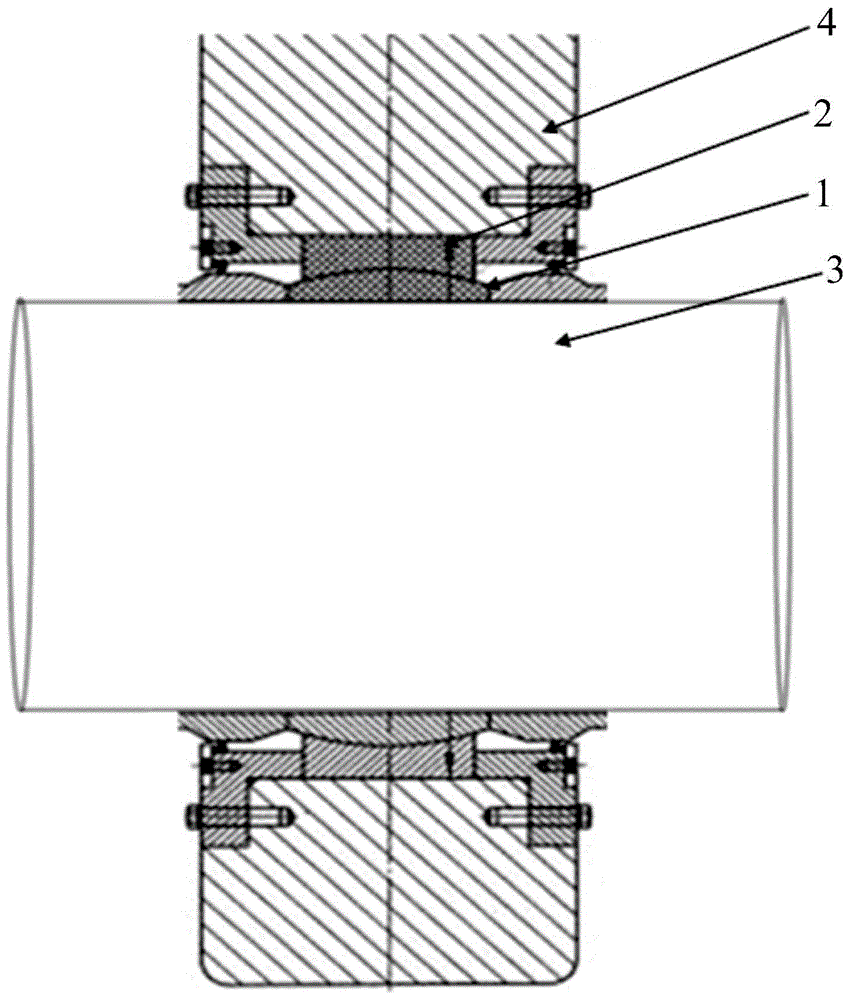

[0034] Such as Figure 6 As shown, in an application of the spherical plain bearing of this embodiment, the shaft 30 is located in the inner ring 10 and closel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com