Method for separating uranium from uranium-containing alkaline sodium carbonate solution

A sodium carbonate and solution technology, applied in the field of separation of uranium, can solve the problems of high uranium-containing wastewater economic efficiency and uranium removal, fluorine removal and waste minimization effects, slow adsorption process, loss of adsorbents, etc. It is convenient for industrial application and operation, the separation processing method is simple, and the cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is illustrated below in conjunction with examples.

[0017] [UO 2 (CO 3 ) 3 ] 4- The configuration: add a quantitative UO 2 (NO 3 ) 2 ·6H 2 O, then add the corresponding Na according to the molar ratio of 1:5 2 CO 3 , the pH at this time was determined to be about 9.58. According to the simulation calculation of the species distribution at this time, within this range, the main form of uranyl in the solution is [UO 2 (CO 3 ) 3 ] 4- .

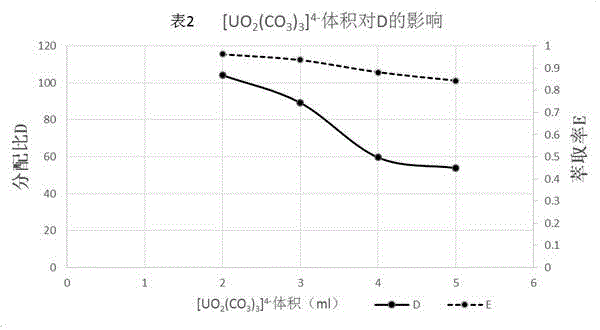

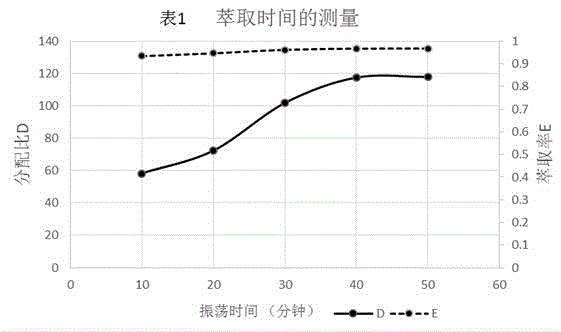

[0018] P 66614 Cl extraction [UO 2 (CO 3 ) 3 ] 4-

[0019] Take P 66614 Cl ionic liquid 0.5ml, take 8.403*10 -3 mol / L (2g / L) [UO 2 (CO 3 ) 3 ] 4- Take 2ml of the solution, extract by shaking, centrifuge to separate the layers, take the lower aqueous solution to adjust pH=3, and measure the distribution ratio.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap