Improved silica ceramic core and preparation method thereof

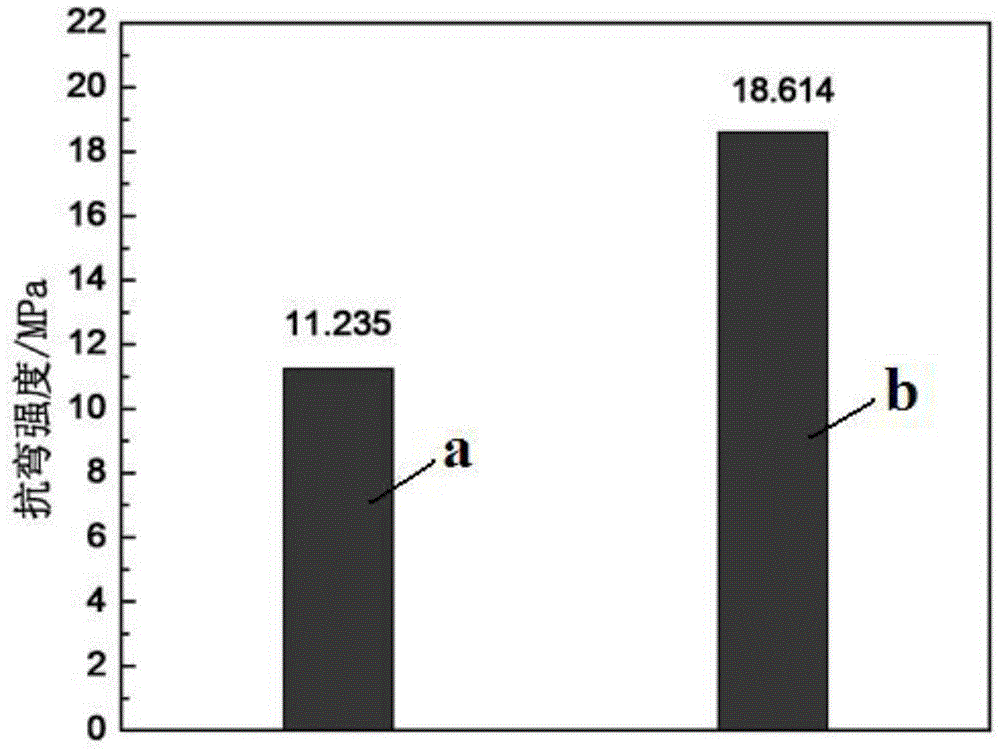

A technology of ceramic core and silicon oxide, which is applied in the field of ceramic core and its preparation, can solve the problems of poor high temperature performance and large firing shrinkage, achieve low high temperature deflection, improve high temperature performance, and have good metallurgical and chemical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

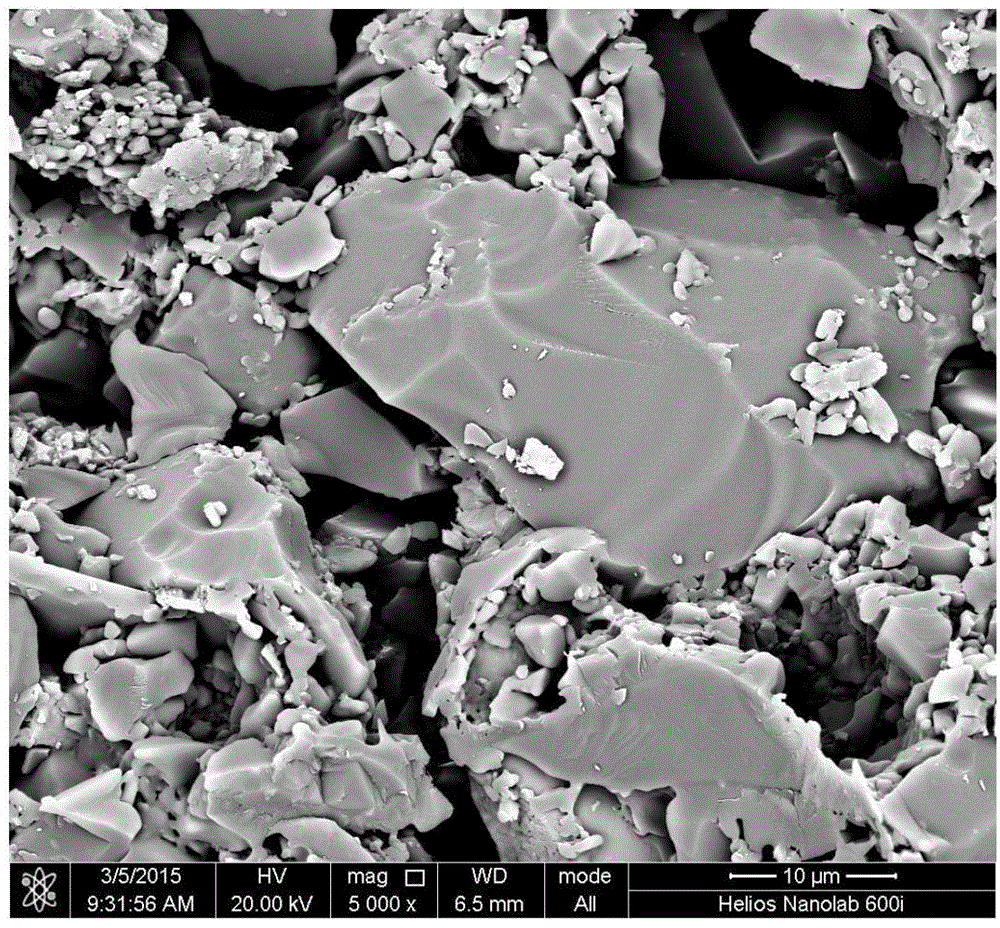

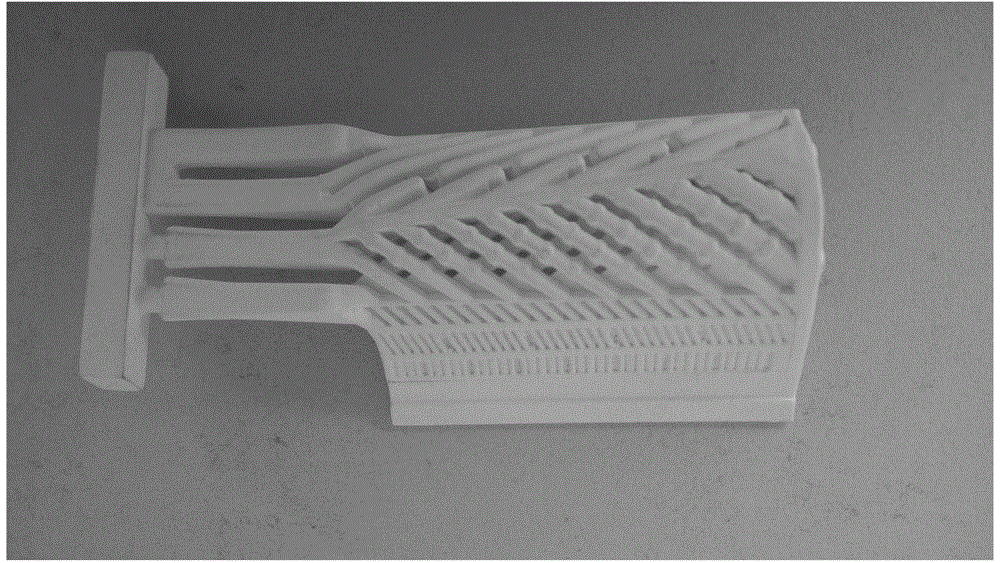

[0017] Embodiment 1: An improved silicon oxide ceramic core of this embodiment is prepared from ceramic slurry and plasticizer; the mass ratio of the ceramic slurry to plasticizer is 100:(10~20 ); the ceramic slurry is formed by mixing 60 to 70 parts of quartz glass powder, 20 to 30 parts of zircon powder and 5 to 15 parts of corundum in parts by mass; wherein the quartz glass powder is made of 200 mesh quartz glass Powder, 300-mesh quartz glass powder and 400-mesh quartz glass powder are mixed, wherein the mass ratio of the 200-mesh quartz glass powder to the 300-mesh quartz glass powder is (4-6):3, and the 200-mesh The mass ratio of quartz glass powder to 400-mesh quartz glass powder is (2-3):1; wherein the zircon powder is mixed with 180-mesh zircon powder and 250-mesh zircon powder, and the 180-mesh zircon powder is mixed with 250-mesh zircon powder. The mass ratio of zircon powder and 250 mesh zircon powder is (2~4):1; wherein said corundum is 200 mesh corundum; said plas...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of the ceramic slurry to the plasticizer is 100:18. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the ceramic slurry is mixed by mass parts by 70 parts of quartz glass powder, 25 parts of zircon powder and 5 parts of corundum; wherein The quartz glass powder is mixed with 200-mesh quartz glass powder, 300-mesh quartz glass powder and 400-mesh quartz glass powder, wherein the mass ratio of the 200-mesh quartz glass powder to the 300-mesh quartz glass powder is 5:3 , wherein the mass ratio of 200 mesh quartz glass powder to 400 mesh quartz glass powder is 5:2; wherein the zircon powder is mixed with 180 mesh zircon powder and 250 mesh zircon powder, wherein the The mass ratio of the 180-mesh zircon powder and the 250-mesh zircon powder is 3:1. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| High temperature strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com