Device and method for rapid preparation of powdered active coke

A preparation device and active coke technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of pipeline layout, large heat preservation, and affecting boiler efficiency, etc., and achieve low infrastructure investment, compact structure, and small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

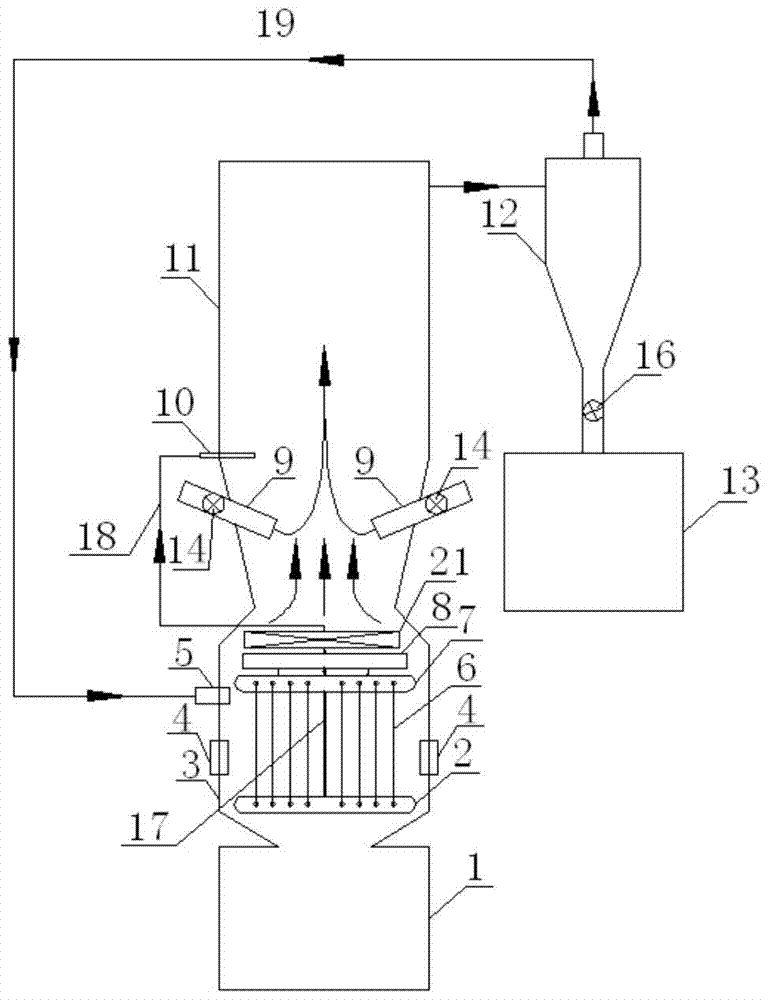

[0030] Depend on figure 1 As shown, a powder active coke rapid preparation device includes a combustion furnace 3, an active coke preparation furnace 11, an ash collection device 1, a gas-solid separation device 12 and a powder active coke collection device 13, wherein the combustion furnace 3 is installed in The upper end of the ash collection device 1, the middle and lower parts of the active coke preparation furnace 11 communicate with the gas outlet of the combustion furnace 3, the gas-solid separation device 12 communicates with the outlet of the active coke preparation furnace 11, and the gas-solid separation device 12 The gas outlet end of the gas-solid separation device 12 communicates with the combustion furnace 3 through the combustible gas pipeline 19, and the solid outlet end of the gas-solid separation device 12 communicates with the powdered active coke collection device 13. The produced powdered active coke enters the powdered active coke collection device 13 th...

Embodiment 2

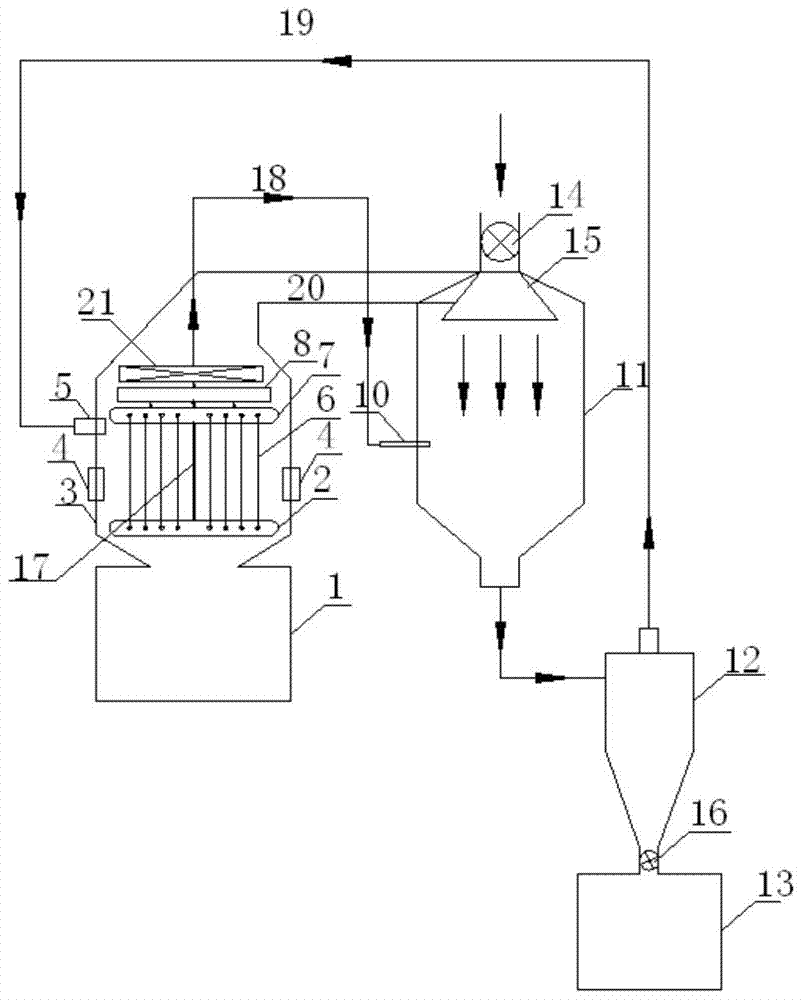

[0036] figure 2 An embodiment in which the combustion furnace 3 and the active coke preparation furnace 11 of the present invention are not coaxial is shown. In this embodiment, the combustion furnace 3 and the powdered activated coke preparation furnace 11 are not coaxial, and the two are connected by a short flue 20 . The gas-solid flow mode in the activated coke preparation furnace 11 is downstream. Raw pulverized coal is fed from the upper end of the active coke preparation furnace 11, and the raw material is evenly distributed when entering the active coke preparation furnace 11 through the pulverized coal uniform distributor 15 arranged under the pulverized coal nozzle 9. This implementation example is applicable to areas with restricted building heights, reducing the total building height. The other structures of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com