Preparation method of three-dimensional nitrogen-doped graphene

A nitrogen-doped graphene, three-dimensional technology, applied in the field of preparation of three-dimensional nitrogen-doped graphene, can solve the problems of complex preparation process, and achieve the effect of simple operation, accelerated reaction and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

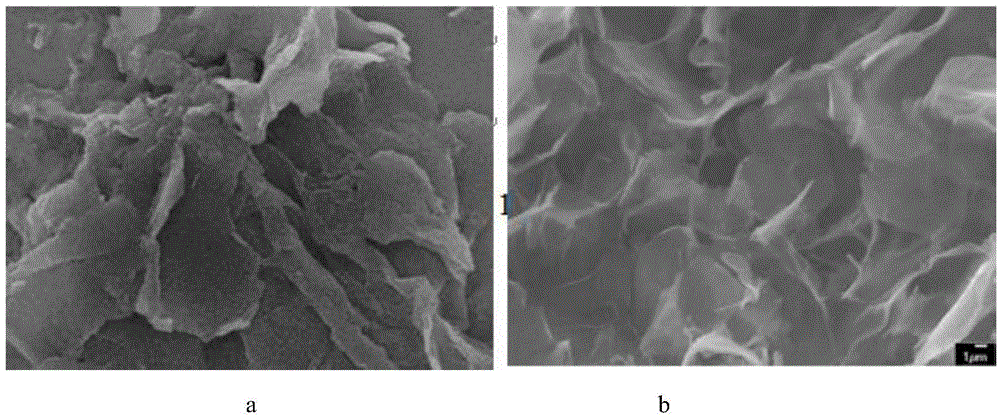

Image

Examples

Embodiment 1 3

[0030] The preparation of embodiment 1 three-dimensional nitrogen-doped graphene

[0031]Utilize the improved Hummer method to prepare graphene oxide (GO), first add 2.5g expanded graphite and 5g sodium nitrate in 500mL beaker, then add 120mL mass concentration to it to be the concentrated sulfuric acid of 98% then, the mixture that obtains is in ice bath condition Stir for 120min under high temperature; then under the condition of vigorous stirring, slowly add 15g of potassium permanganate to the obtained mixture for reaction, the temperature of the reaction is controlled below 20°C; remove the ice bath after completing the addition of potassium permanganate equipment, the resulting reaction product was stirred overnight at room temperature. Finally, 150 mL of secondary water was added dropwise to the beaker under vigorous stirring, and the reaction temperature rose rapidly to 98° C., and foam generation was observed, and the color of the reaction product in the beaker turned...

Embodiment 2

[0040] The ratio of the addition of thioacetamide and graphene oxide is 3:1, and other conditions are with embodiment 1. The obtained nitrogen-doped three-dimensional graphene has a nitrogen content as high as 6.7%, and the capacity retention rate is as high as 94.5% after charging and discharging 10,000 times.

Embodiment 3

[0042] The ratio of the addition of thioacetamide and graphene oxide is 8:1, and other conditions are with embodiment 1. The obtained nitrogen-doped three-dimensional graphene has a nitrogen content as high as 8.5%, and the capacity retention rate is as high as 96.1% after charging and discharging 10,000 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com