Sealing bottle plug

A bottle stopper and stopper body technology, applied in the field of sealing bottle stoppers, can solve problems such as loss of seal, affecting the quality of objects in the bottle, and difficulty in ensuring the sealing effect of the bottle mouth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

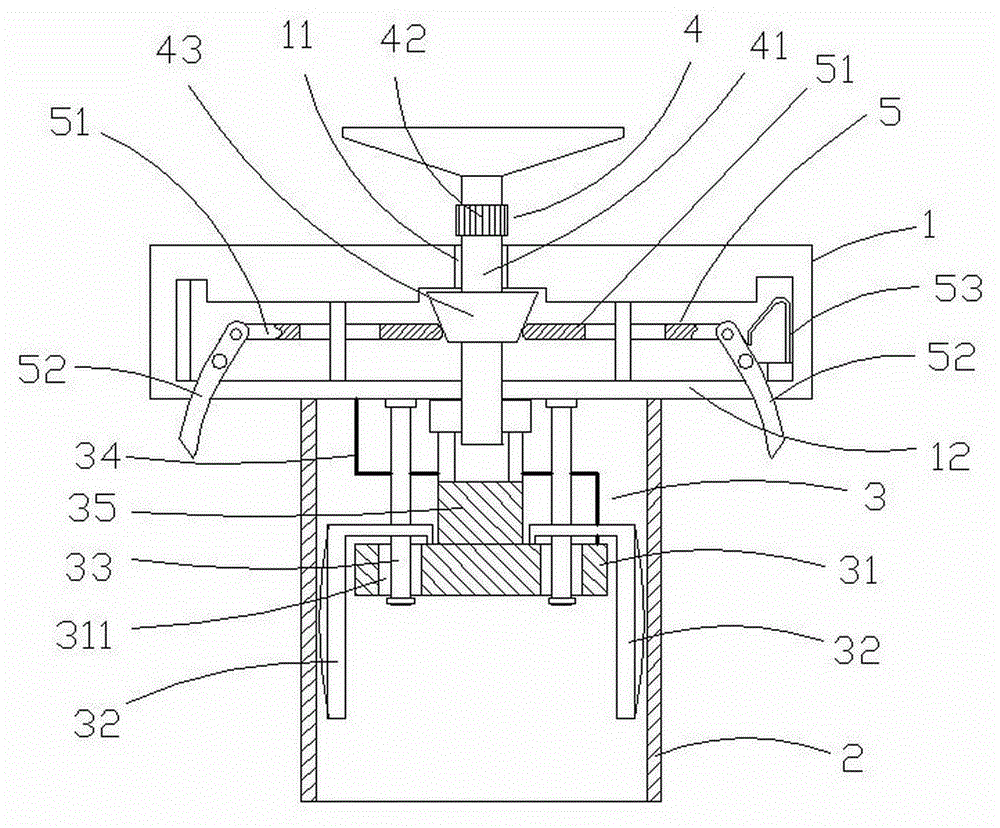

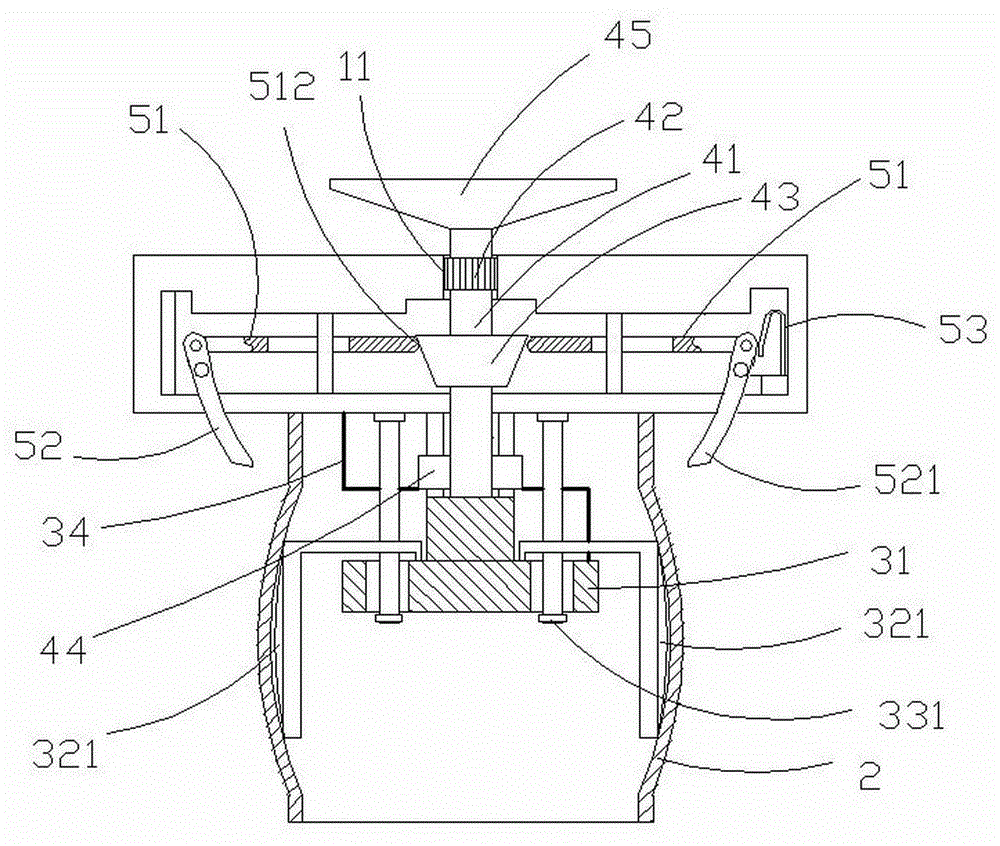

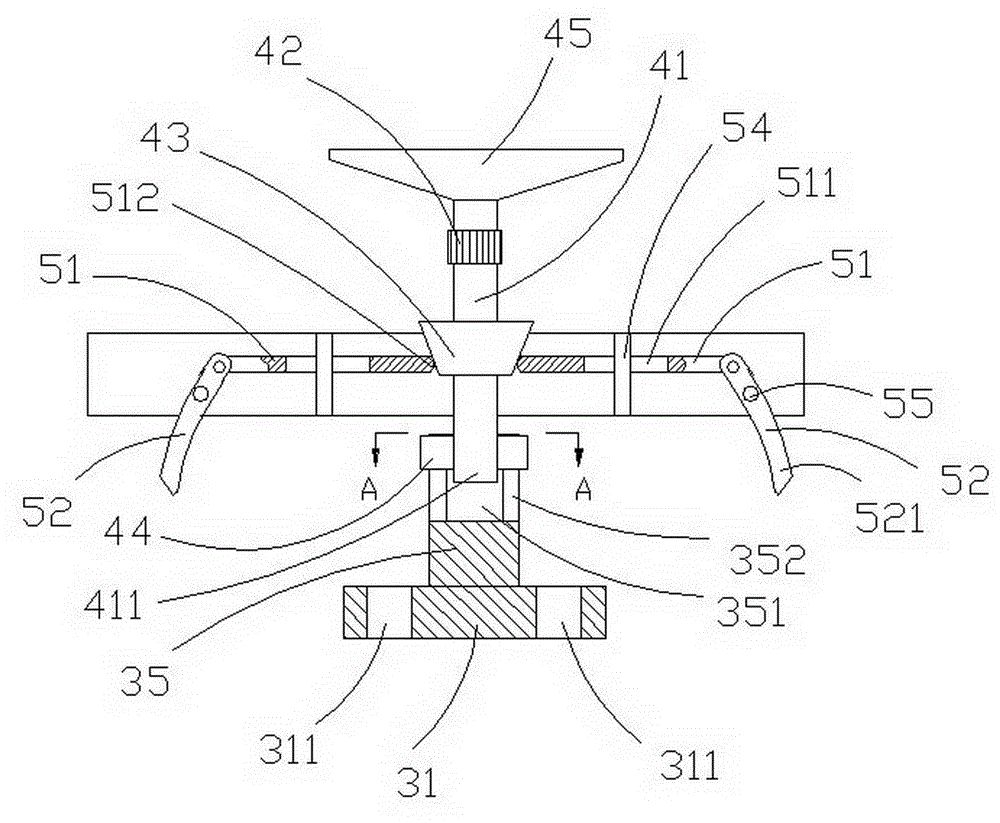

[0017] like figure 1 As shown in -6, a sealed bottle stopper includes an upper cover body 1, an elastic plunger body 2, an expansion mechanism 3, a rotation mechanism 4, and a locking member 5. The upper cover is connected with the elastic plunger body, the elastic plunger body 2 is made of plastic material, the bottom of the elastic plunger body is sealed and integrated with the body, and the inner cavity of the elastic plunger body 2 is provided with an expansion mechanism 3 The drive plate 31 of the expansion mechanism is provided with four support arms 32 equally arranged around the circumference, the connecting portion 323 of the support arm is clamped on the drive plate 31, and the outer surface of the pressing portion 321 of the support arm longitudinally surrounds the elastic column The inner peripheral walls of the plug body 2 are in contact with each other, and the positioning guide pin 33 fixed on the baffle plate 12 passes through the crosspiece 322 of the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com