Posture and moving track positioning system and method of robot grabbing online workpiece

A robot system and motion trajectory technology, applied in manipulators, manufacturing tools, etc., can solve the problems of complex operation, poor robustness, and large position calibration error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

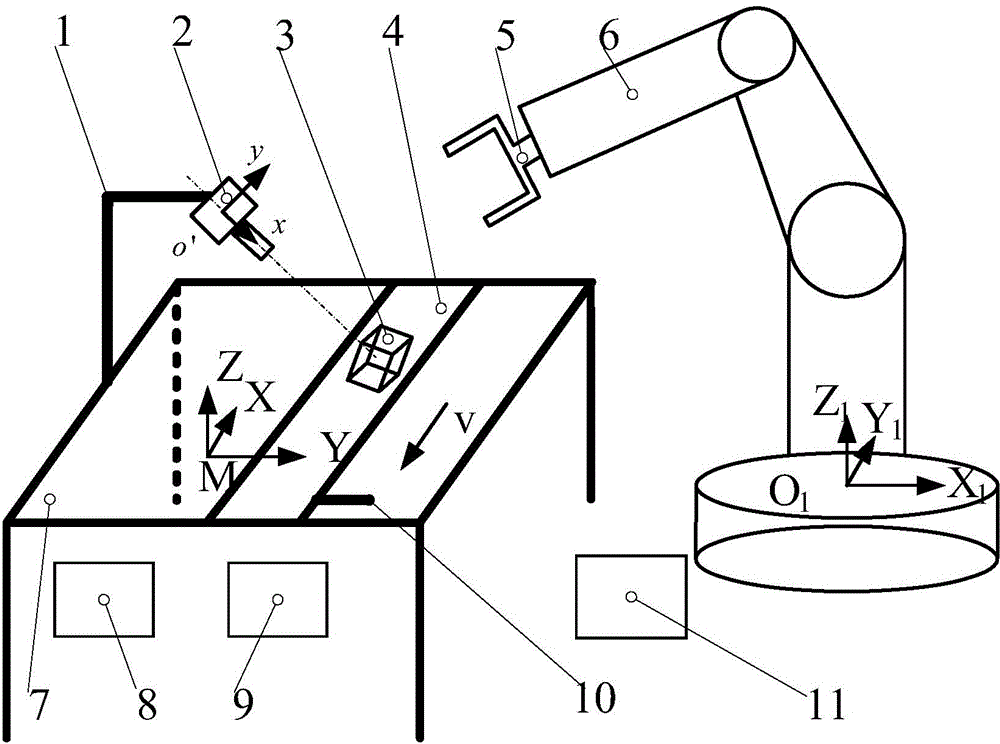

[0063] refer to figure 1 In this embodiment, the robot pose and motion trajectory positioning system for grabbing online workpieces includes a camera bracket 1, an industrial camera 2, a workpiece to be measured 3, a workpiece conveyor belt 4, an end effector 5, a robot system 6, a workbench 7, an image A processor 8 , a worktable control device 9 , a displacement sensor 10 and a robot control device 11 . The industrial camera 2 is installed on the camera bracket 1, and the optical axis of the camera is installed at an appropriate downward angle to the vertical line, so that it can acquire the axial side image of the workpiece on the conveyor belt and the initial position of the robot end effector. The camera and industrial robot are installed on both sides of the motion platform to ensure that the robot arm does not block the camera's field of view. Photoelectric sensors are installed next to the conveyor belt to detect whether workpieces enter the camera's field of view. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com