Efficient gradualness polishing method and device based on gas-liquid-solid three-phase abrasive particle flow

A technology of polishing device and abrasive flow, which is applied in the direction of grinding driving device, grinding/polishing equipment, and parts of grinding machine tools, etc., which can solve the problem of low efficiency of processing workpieces, low degree of automation, and inability to ensure uniform surface processing of workpieces Uniformity and other issues to achieve the effect of improving processing efficiency and ensuring processing quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

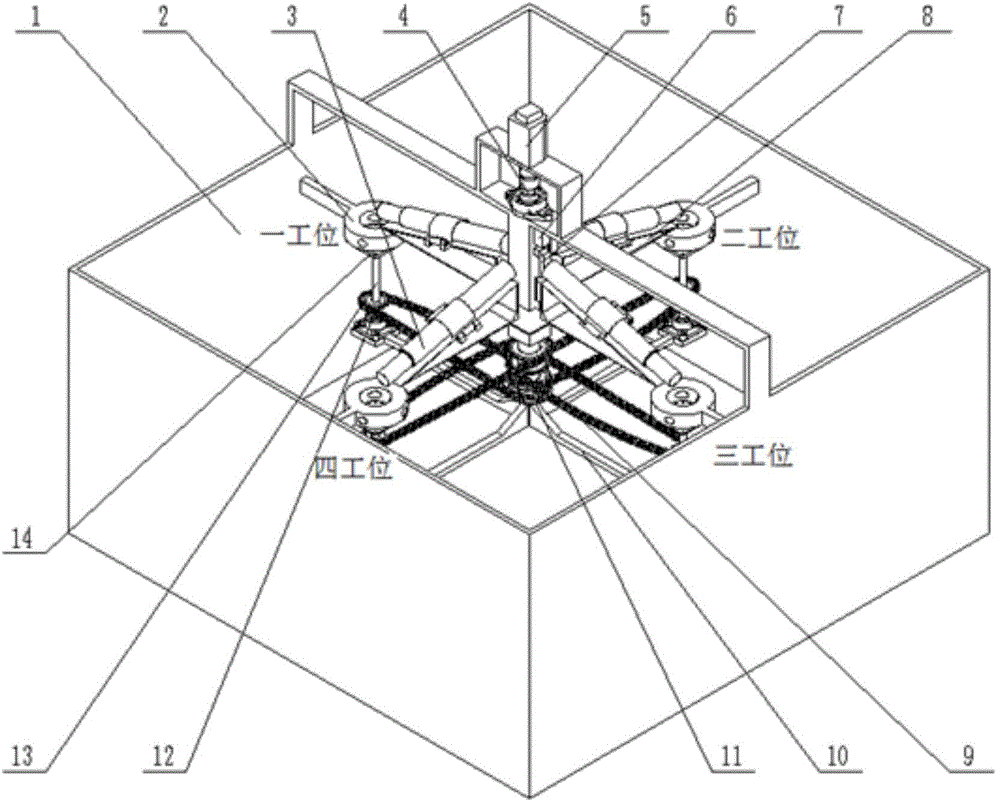

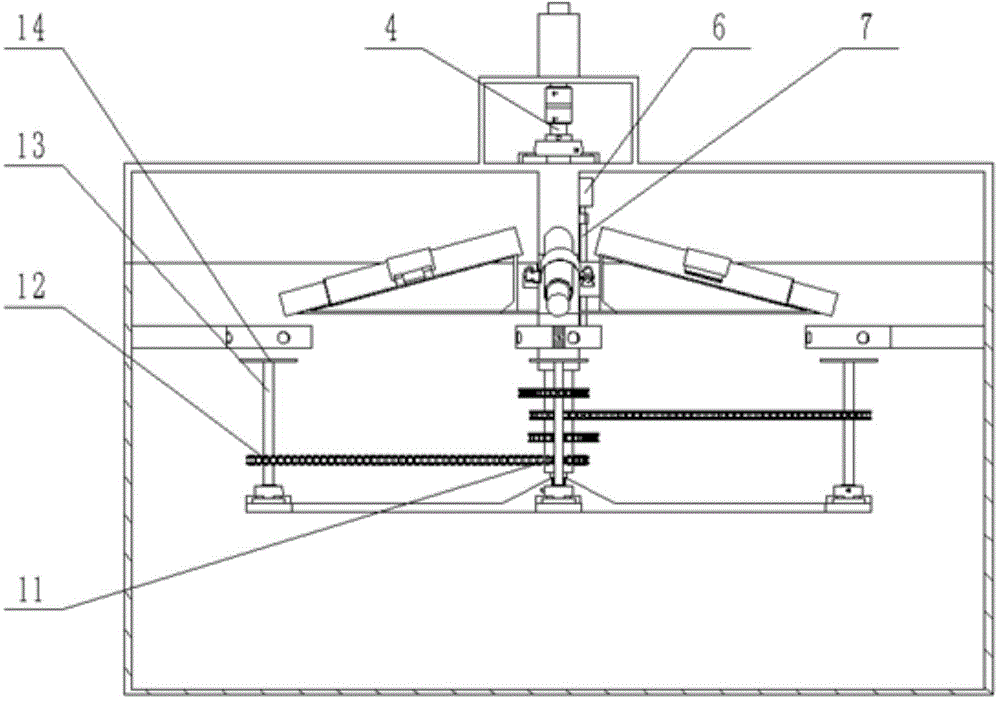

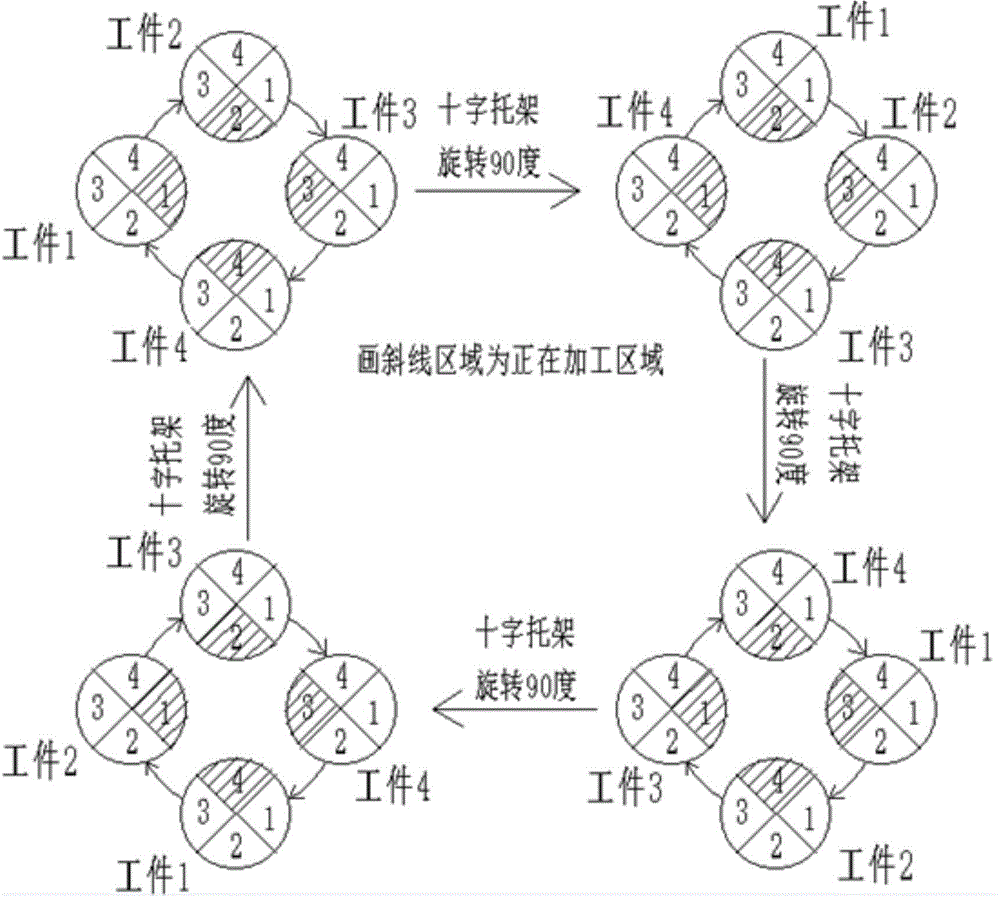

[0026] Such as Figure 1~4 As shown, the high-efficiency progressive polishing device based on gas-liquid-solid three-phase abrasive flow includes a control system, a chamber frame 1, a stepping motor, a driving mandrel, a driving sprocket 11, a driven gear, a chain 9, a cross Bracket 10, four-station rotating device, lifting mechanism and ultrasonic bubble generator 3, the cavity frame 1 is provided with a crossbeam, the top of the active mandrel 4 passes through the crossbeam to connect to the stepping motor 5, and the stepping motor 5 The motor base is fixed on the beam; the bottom end of the active mandrel 4 is affixed to the center of the cross bracket 10; the four ends of the cross bracket 10 are provided with four vertically installed driven mandrels 13 , the bottom end of the driven mandrel 13 is connected to the cross bracket 10 through a bearing, and the top end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com