BG42 stainless steel medical clamp and manufacturing method thereof

A technology of stainless steel and a manufacturing method, which is applied in the field of manufacturing process of oral medical jaws, can solve the problems of easy discoloration of welding places, poor welding performance, and difficult welding of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the accompanying drawings.

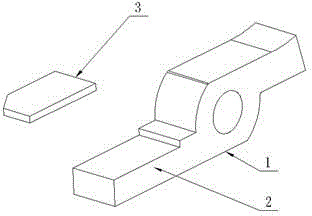

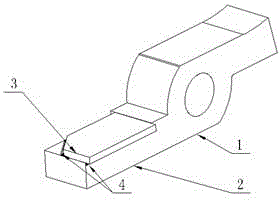

[0015] Such as Figure 1-2 As shown, the stainless steel BG42 medical pliers described in this embodiment includes a pliers body 1 with a pliers head, and a step is provided on the pliers head part 2, and stainless steel BG42 3 is welded on the steps by a paste nickel-based solder 4, wherein the The pliers body 1 is made of a low-carbon stainless steel material above HRC30 obtained by quenching, and the stainless steel BG42 is made of a mixture of C, Si, Mn, Cr, Mo and V, wherein the mass percentage of C is 1.0 -1.2, the mass percentage of Si is 0.2-0.4, the mass percentage of Mn is 0.4-0.6, the mass percentage of Cr is 14-15, the mass percentage of Mo is 3-5, and the mass percentage of V is 1.1-1.3; The paste nickel-based brazing filler metal is a mixture of Cr, B, Si, Fe, C, P and Ni, wherein the mass percentage of Cr is 6-8, the mass percentage of B is 2.75-3.5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com