Forming mold for automobile exhaust system heat shield

An automobile exhaust system and forming technology, which is applied in the stamping and forming of automobile exhaust system parts and the forming of automobile parts, can solve problems such as easy cracking of material plates, avoid easy cracking, improve processing efficiency, The effect of ensuring the quality of stamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

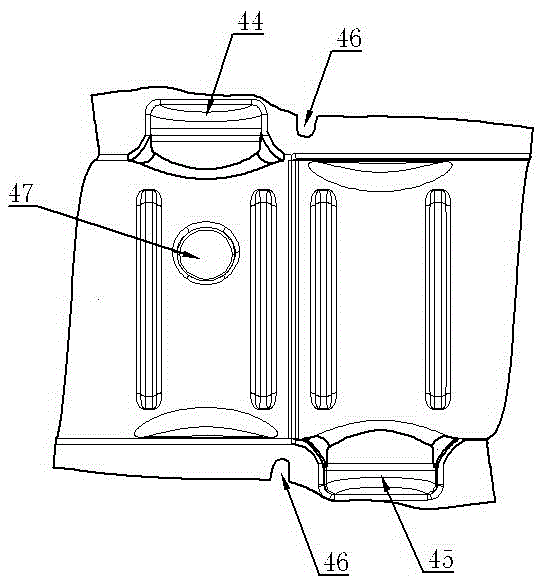

[0021] See Figure 4 ~ Figure 9 , the forming processing mold of the automobile exhaust system heat shield includes an upper mounting plate 1 and a lower mounting plate 2, a pre-forming module and a forming module, and the pre-forming module and the forming module are installed on the upper mounting plate 1 and the lower mounting plate between 2.

[0022] Wherein, the preforming module includes the preformed upper formwork 3 installed on the lower part of the upper mounting plate 1 and the preformed lower formwork 4 installed on the lower mounting plate 2 through the first lower mold foot 15 and the second lower mold foot 16. The lower part of the upper template 3 is fixed with a preformed upper mold 7, the preformed lower template 4 is equipped with a preformed lower backing plate 9, and the preformed lower backing plate 9 is equipped with a preformed pressure plate 8, a preformed pressure plate 8 A preformed lower die 10 is installed inside, and the forming surface of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com