Hexagonal hole punching device

A punching device and a technology for hexagonal holes, applied in the field of punching hexagonal holes, can solve the problems of simple structure, burr generation, increased processing cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

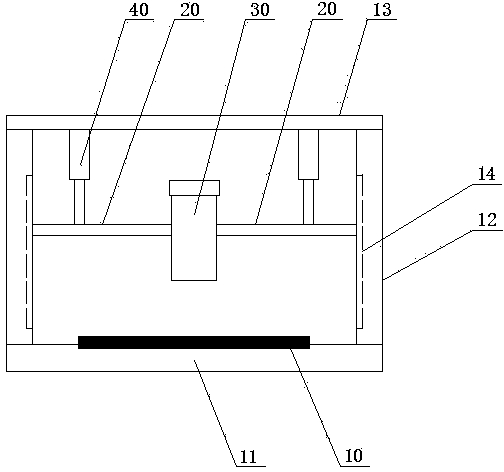

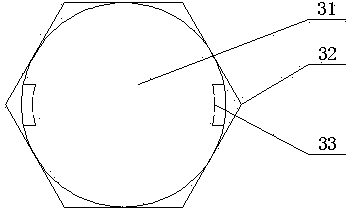

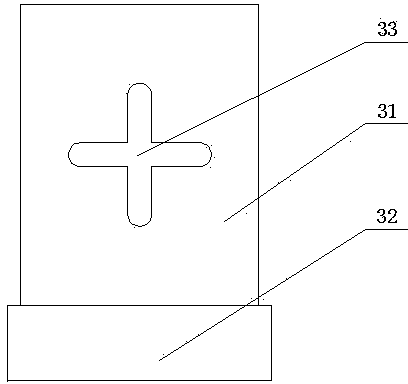

[0018] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0019] Such as Figure 1 to Figure 5 As shown, a punching device for hexagonal holes includes a support, and the support includes a working platform 11 for placing the workpiece 10 to be punched, and longitudinal support arms 12 are arranged on both sides of the working platform 11, and the two support arms 12 are respectively transversely A clamping member 20 capable of moving longitudinally along the support arms 12 is connected, specifically, a slide slot 14 for longitudinal movement of the clamping member 20 can be provided on the two support arms. In the present invention, the two clamping parts 20 are arranged opposite to each other, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com