Spraying head capable of improving semiconductor plasma processing evenness

A technology for processing uniformity and plasma, which is applied in semiconductor/solid-state device manufacturing, injection devices, injection devices, etc., can solve the problems of low gas utilization rate and insufficient uniformity, and achieve the goal of increasing utilization rate and improving uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

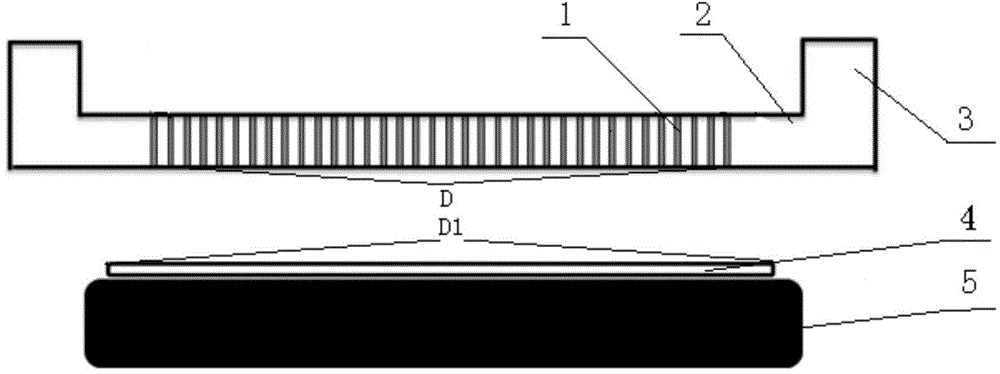

[0017] The shower head of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The advantages and features of the present invention will become clearer from the following description. In this paper, the formation of plasma by radio frequency ionization is taken as an example to describe the shower head of the present invention. It should be noted that all the drawings used in the embodiments are simplified diagrams to facilitate the explanation of the embodiments.

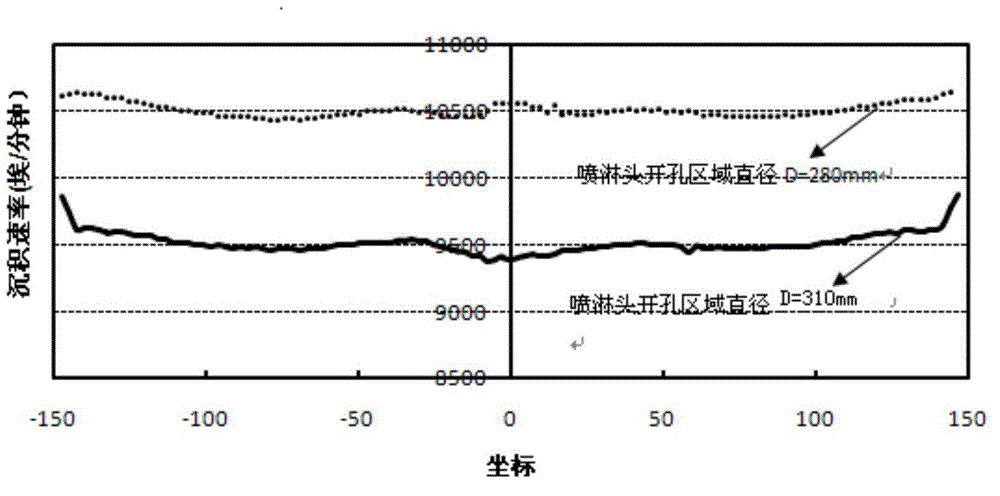

[0018] The shower head of the present invention forms an opposite surface with the loading platform, and is arranged in the reaction chamber, and the area of the opening of the shower head is smaller than the area of the loaded objects. The opening area of the shower head is provided with a plurality of through holes for spraying the reaction gas into the reaction chamber in the form of a shower. These through-holes are distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com