Cutting rod lotus root digging machine

A lotus root digging machine and pole cutting technology, which is applied in the field of paddy field operation machines, can solve the problems affecting the efficiency of lotus root harvesting and low labor efficiency, and achieve the effects of saving labor, improving operation quality, and ensuring the level and balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

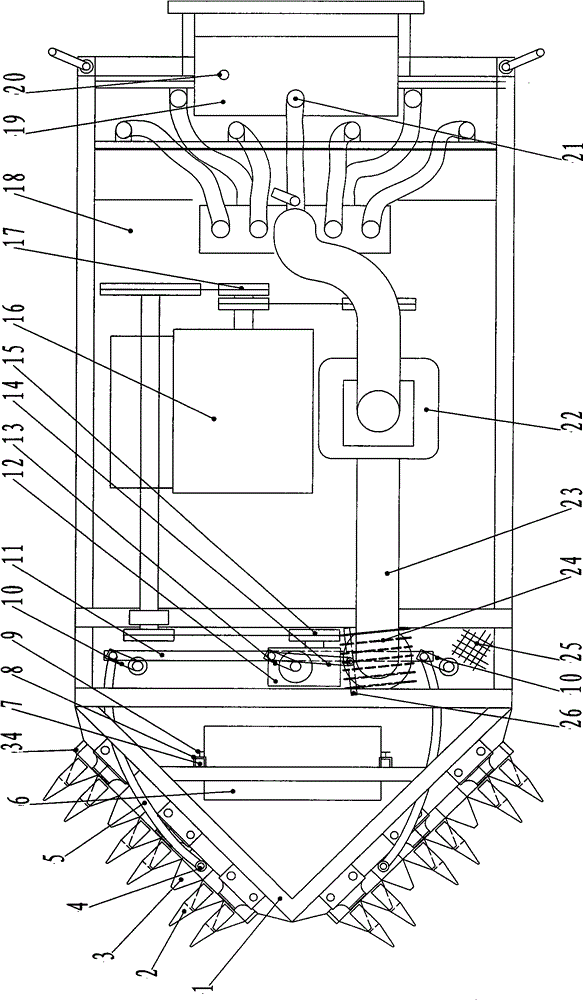

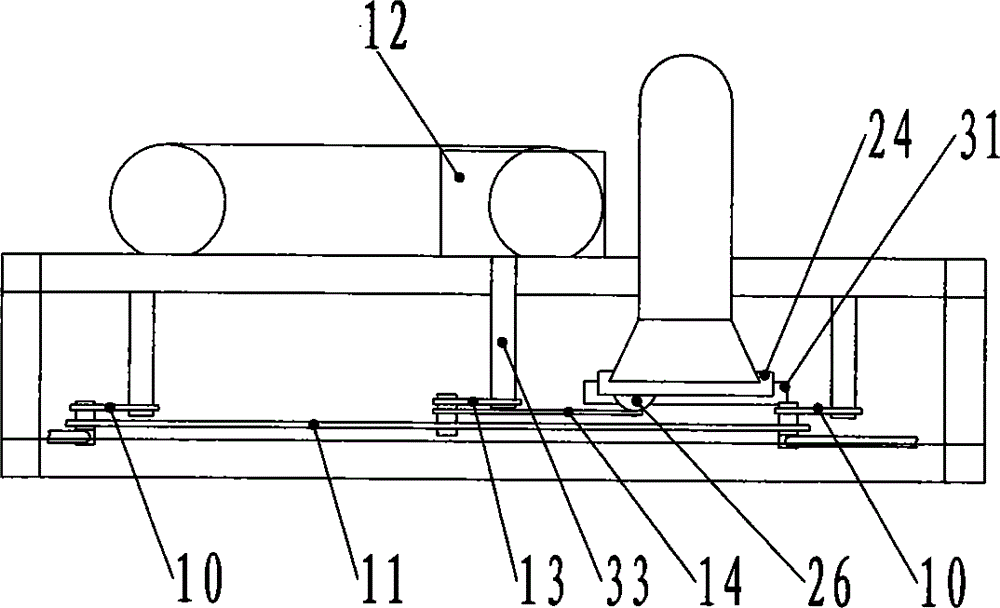

[0017] Below in conjunction with accompanying drawing and specific embodiment the root cutting machine of the present invention is further described:

[0018] figure 1 It is a schematic structural view of a cutting rod and lotus root digging machine of the present invention, figure 2 yes figure 1 bottom view of image 3 yes figure 2 A-A sectional view in . Among the figure, this pole-cutting lotus root machine comprises a buoyancy box 18, an engine 16 and a water pump 22 are arranged above the buoyancy box 18, and a water spray pipe, a nozzle and a nozzle adjustment device 30 for adjusting the direction of the nozzle are arranged at the buoyancy box 18 rear end. The front end of the buoyancy box 18 is provided with a symmetrical triangular cutter frame 1, and the two sides of the cutter frame 1 are provided with a plurality of linkage blades 3, and the blade 3 is triangular in shape. There is a mouth guard 2, the rear tail of the mouth guard 2 is fixed on the cutter fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com