Method for establishing 3D digital maintenance platform of aircraft based on 3D laser scanning technology

A technology of three-dimensional laser and scanning technology, applied in the field of three-dimensional digital maintenance system platform, can solve the problems of large gap and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

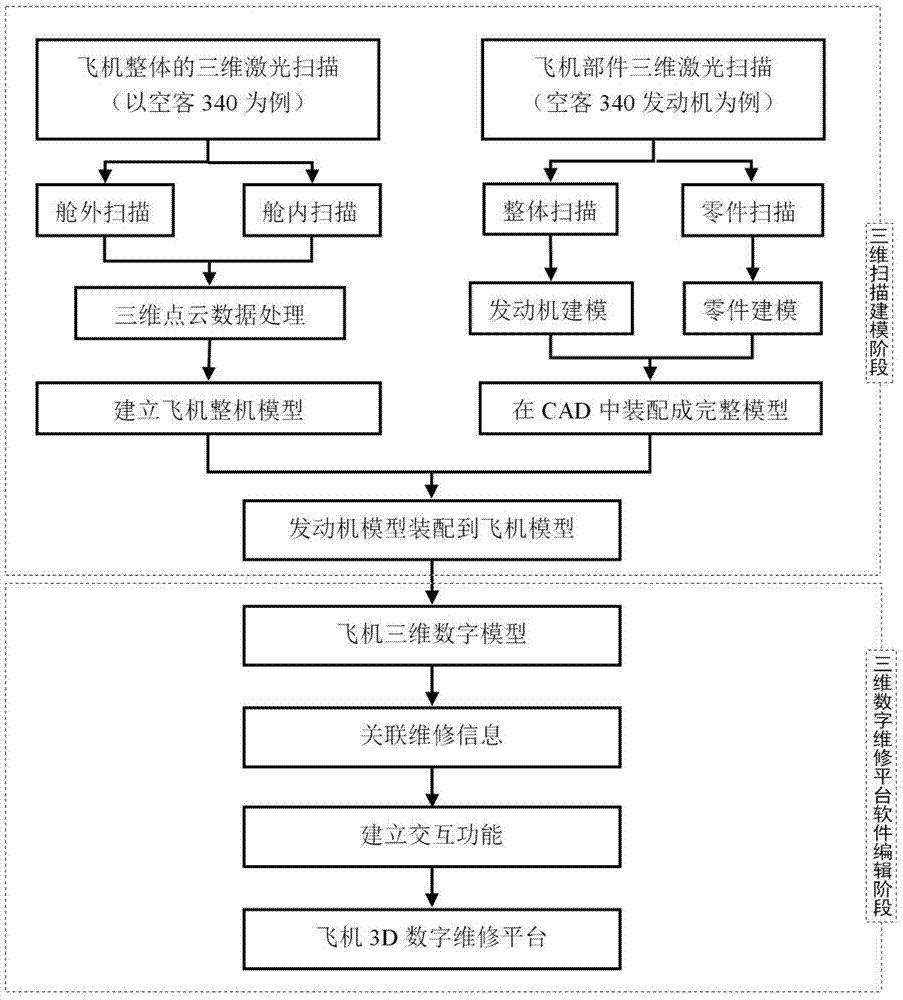

[0037] Use Z+Fimager5010C 3D laser scanner to scan the Airbus 340, use the reverse modeling software GeomagicStudio to model the scanned data, and finally complete the assembly in the CAD software, and establish a software platform with maintenance functions. The specific operation process as follows:

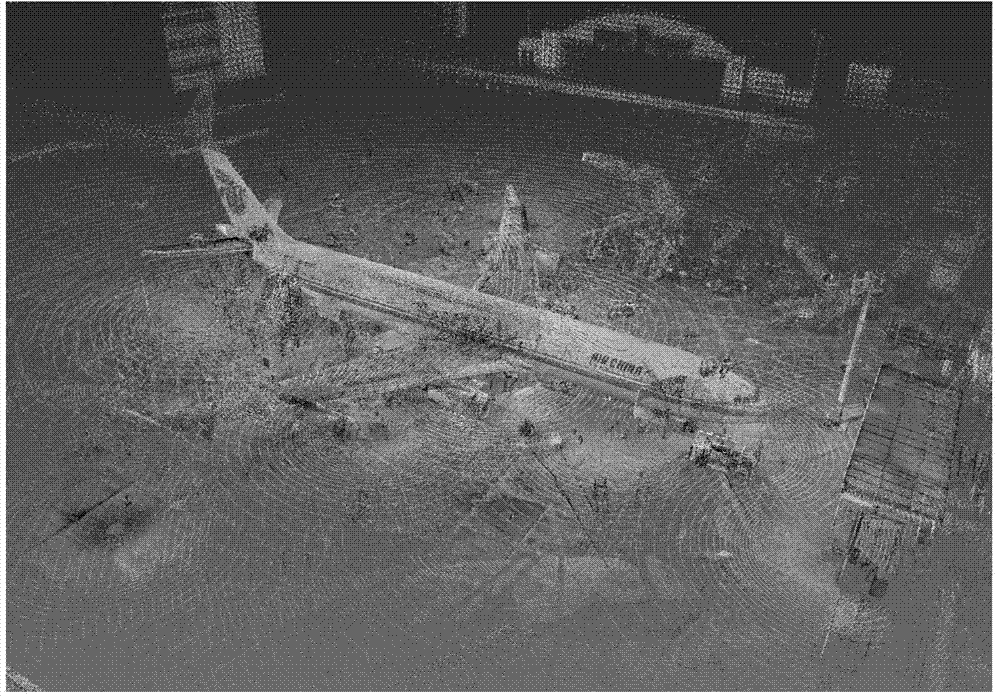

[0038] Step 1: Use the Z+Fimager5010C 3D laser scanner to scan the entire aircraft Airbus 340, including the inside and outside of the cabin. The Airbus 340 is a scanning object with a relatively complex structure. In order to collect comprehensive data, it is necessary to perform multi-station scanning on different parts of the aircraft, including engines, wings, fuselage, empennage, landing gear, cockpit, and cabin.

[0039] Step 2: Import the data acquired by the Z+Fimager5010C 3D laser scanner into the computer for processing. The process includes the following sub-steps:

[0040] ① Attaching color: The data obtained by the Z+Fimager5010C 3D laser scanner includes the 3D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com