Integrated stop valve

A globe valve, integrated technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of leakage of medium in the pipeline, many leakage points, short service life, etc., and achieve the effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

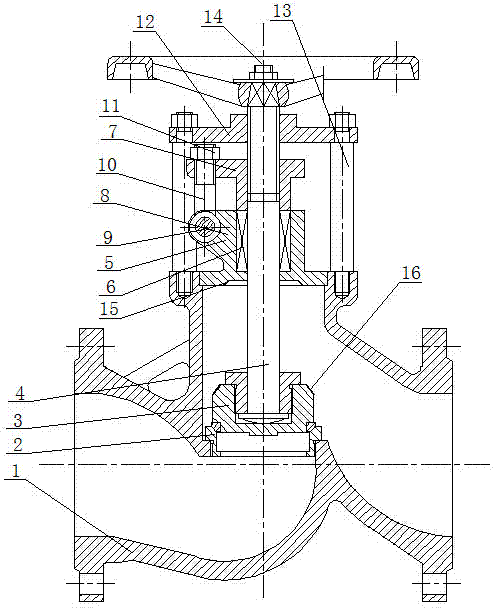

[0010] Such as figure 1 As shown, the present invention includes a valve body 1, a valve seat 2 is installed in the center of the valve body 1, a valve disc 3 is arranged on the valve seat 2, and a valve stem 4 is connected to the upper end of the valve disc 3; There is a stuffing box 5, and the upper center of the valve body 1 is provided with a cavity matching the lower end of the stuffing box 5, and the lower end of the stuffing box 5 is arranged in the cavity at the center of the side of the valve body 1 and sealed and welded; the stuffing box 5 is set There is packing 6 and it is compressed by packing gland 7. Two ear seats 8 parallel to each other are integrally arranged on both sides of the upper end surface of stuffing box 5, and swing bolts 10 are connected between the two ear seats 8 through pin shafts 9. The screw end of the swing bolt 10 passes through the packing gland 7 upwards and is fixed by a nut 11 .

[0011] A nut seat 12 is threadedly connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com