One-piece two-way low-friction cable node of single-layer reticulated shell structure with suspension cables

A single-layer reticulated shell, integrated technology, used in building components, building structures, roofs, etc., can solve the problems of cable prestressing, unfavorable multi-functional use of buildings, and inconvenient hanging of suspension cable structures. Connection, loss reduction, low friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

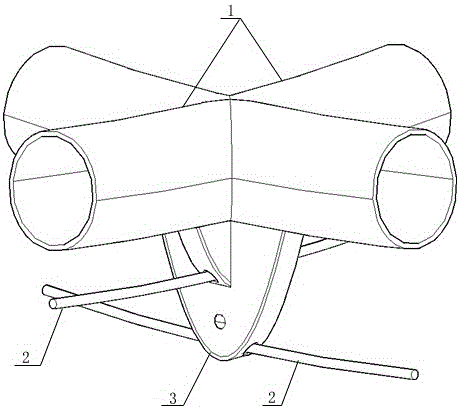

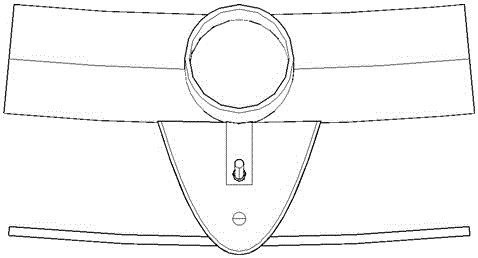

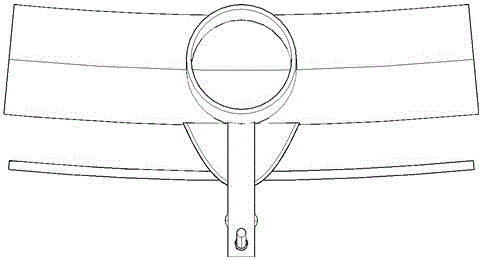

[0019] Embodiment 1: as Figure 1-6 As shown, the integrated two-way low-friction cable node of the suspension cable single-layer reticulated shell structure, the suspension cable single-layer reticulated shell structure includes a rigid reticulated shell 1 and a stay cable 2, and the rigid reticulated shell 1 is a two-way orthogonal Arranged grid structure, the cables 2 in two directions are arranged below or above the rigid bars of the rigid reticulated shell 1 at the same time, and the cables 2 in two directions below or above the rigid reticulated shell 1 pass through an integrated two-way low friction The drag cable node 3 is connected to the rigid reticulated shell 1.

[0020] The integrated two-way low-friction cable node 3 includes an A-direction lug 4a arranged along a rigid rod in one direction of the rigid reticulated shell 1, a pulley 4b in the A direction, and a rigid rod arranged along the other direction of the rigid reticulated shell 1. B direction lug 5a and ...

Embodiment 2

[0022] Embodiment 2: The integrated two-way low-friction cable node includes multiple A-direction pulleys 4b and multiple B-direction pulleys 5b, and the multiple A-direction pulleys 4b and multiple B-direction pulleys 5b pass through the corresponding A-direction The pin shaft 4c and the B-direction pin shaft 5c are rotationally connected with the A-direction lug 4a and the B-direction lug 5a respectively, and the plurality of A-direction pulleys 4b and the plurality of B-direction pulleys 5b are respectively along the axis parallel to the corresponding cable 2 Arranged in the same direction, setting multiple pulleys can reduce the local stress at the contact point between the cable and the pulley, and make the force on the cable more uniform. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com