Vacuum glass sealing and connecting structure, semi-finished product of vacuum glass sealing and connecting structure, and sealing and connecting method of vacuum glass sealing and connecting structure

A technology of vacuum glass and bonding structure, applied in the field of vacuum glass sealing structure, can solve the problems of unfavorable long-term stable use of finished products, complicated processing equipment and process, packaging stress on glass plates, etc., and achieves good product quality stability, The effect of product intrinsic quality assurance and easy production process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

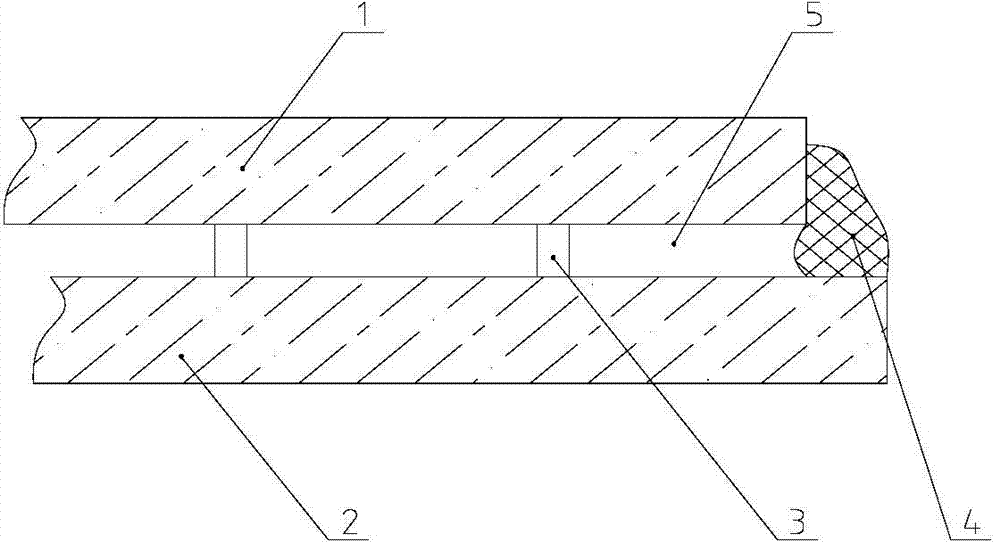

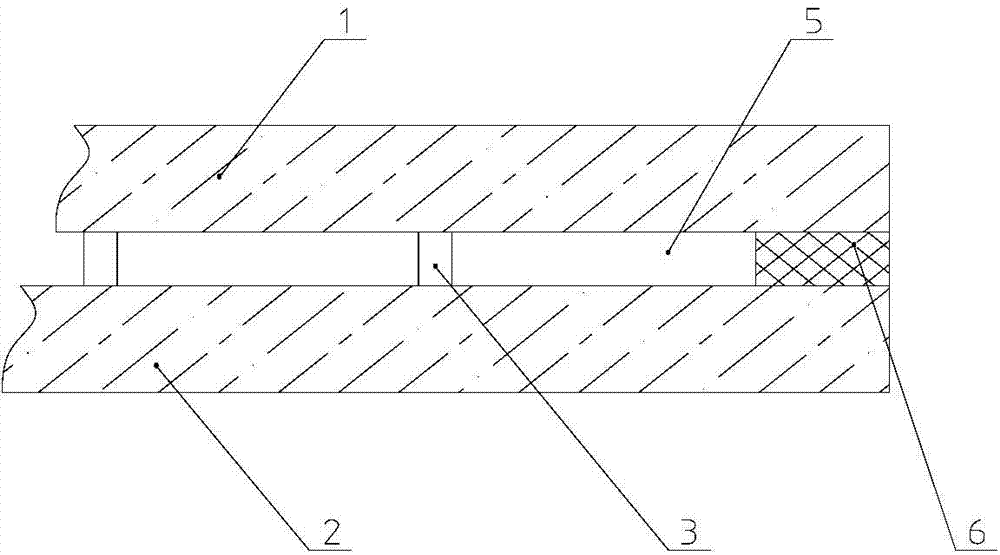

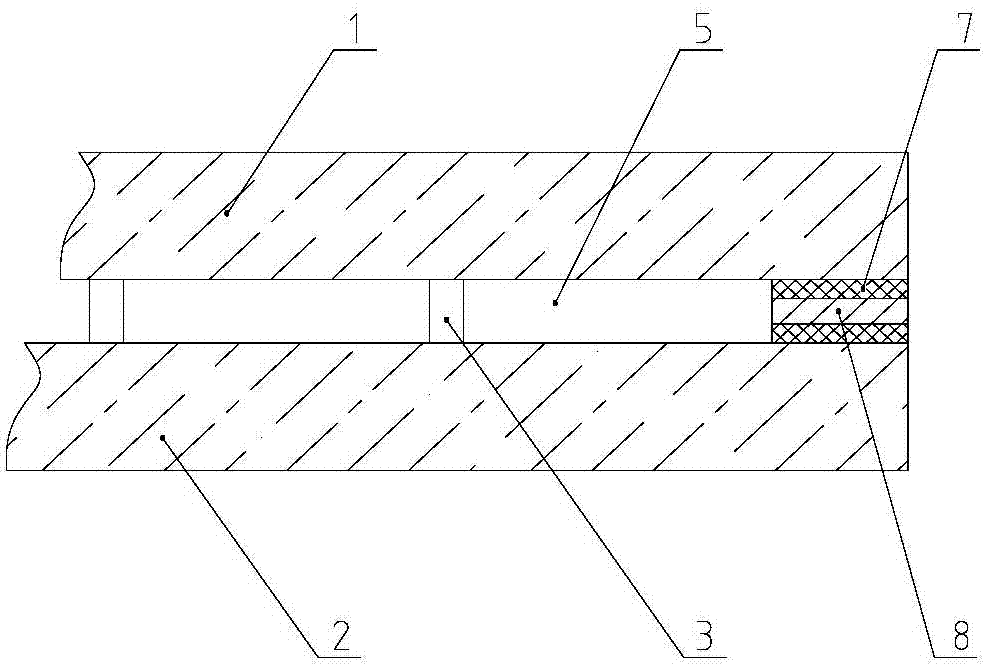

Embodiment 1

[0066] The metal strip 12 in Embodiment 1 is a planar section type, but considering that the glass frit slurry 11 coated on the metal strip 12 may flow when heated and molten, and cause the sealing edge to be irregular after flowing, It affects the appearance, and it is easy to cause the molten glass filling between the metal strip 12 and the upper and lower glass plates 1, 2 to be untrue. Figure 7 In the shown embodiment 2, a U-shaped cross-section type metal strip 13 has been adopted, each of which has a bending edge close to the upper and lower glass plates 1, 2 to be sealed on the two sides of the plane main body. surface. In this way, the two bending edges can restrict the flow of the glass powder slurry 11 in the heated and molten state, so as to ensure the glass in the molten state between the metal strip 12 and the upper and lower glass plates 1 and 2. The powder paste 11 is melted and molded in a limited space, and the metal strip 12 is firmly connected with the gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com