Treatment system and technique for derived wastewater generated by incineration fly ash pretreatment

A waste water treatment system and fly ash incineration technology, applied in water/sludge/sewage treatment, general water supply saving, water/sewage multi-stage treatment, etc., can solve environmental pollution, waste of water resources, low organic matter concentration and other problems, To achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

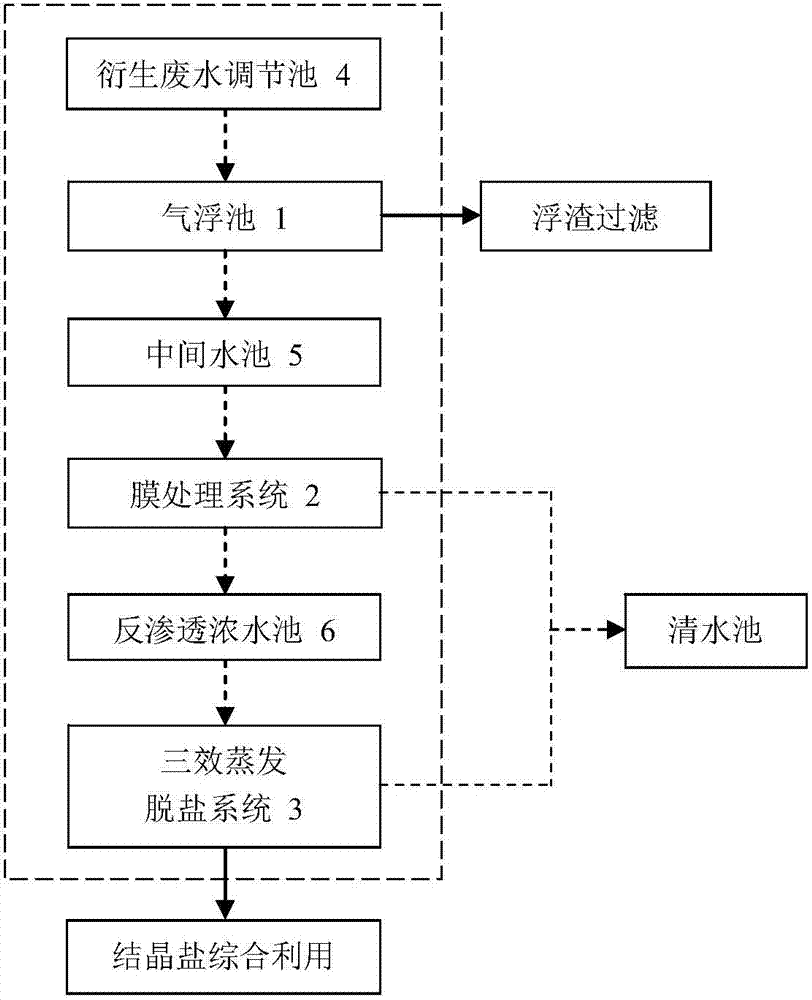

[0018] Such as figure 1 As shown, a derivative wastewater treatment system produced by incineration fly ash pretreatment, which includes a derivative wastewater regulating tank 4, an air flotation tank 1, an intermediate pool 5, a membrane treatment system 2, and a reverse osmosis concentrated water tank 6 arranged in sequence along the flow direction and three-effect evaporative desalination system 3; among them,

[0019] Derived wastewater regulating tank 4 is used to store the wastewater after rinsing the incinerated fly ash, and its water outlet is connected with the water inlet of the air flotation tank 1;

[0020] Air flotation pool 1, its water outlet links to each other with the water inlet of intermediate pool 5;

[0021] The middle pool 5 is used to store air flotation water, and its water outlet is connected to the water inlet of the membrane treatment system 2;

[0022] Membrane treatment system 2, including the multi-media filter, microfiltration membrane system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com