A waste aluminum alloy crushing, cleaning and recycling device

A recycling device and aluminum alloy technology, applied in the field of waste aluminum alloy crushing, cleaning and recycling devices, can solve the problems of poor cleaning effect of cleaning liquid, waste of manpower, material resources, complicated engineering quantity, etc., and achieve significant cleaning effect, improve quality, and improve Effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

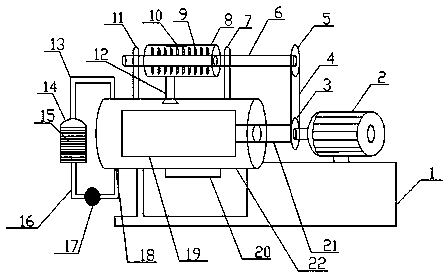

[0015] Example: such as figure 1 As shown in , a waste and old aluminum alloy crushing, cleaning and recycling device includes: a frame 1, a motor 2, a first pulley 3, a belt 4, a second pulley 5, a first rotating shaft 6, a first bracket 7, and a crushing box Body 8, crushing knife 9, feed port 10, second bracket 11, feed channel 12, first conduit 13, liquid storage tank 14, second conduit 16, filter pipe 17, filter screen 18, agitator 19, discharge Port 20, second rotating shaft 21, cleaning box 22; the cleaning box 22 is arranged on the left end of the frame 1, the crushing box 8 is arranged on the top of the cleaning box 22, and the feeding channel 12 is vertically connected to the cleaning box. The box body 22 and the crushing box body 8, the motor 2 is arranged on the right end of the frame 1, the first rotating shaft 6 is horizontally arranged inside the crushing box body 8, and the left end of the first rotating shaft 6 is fixed to the cleaning box body through the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com