Double-cone-shaped main runner sprue bushing

A technology of sprue bushing and main flow channel, which is applied in the field of injection mold mechanism design, can solve the problems of simultaneous independent pouring, etc., and achieve the effects of easy processing, smooth material removal, and reduced injection molding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

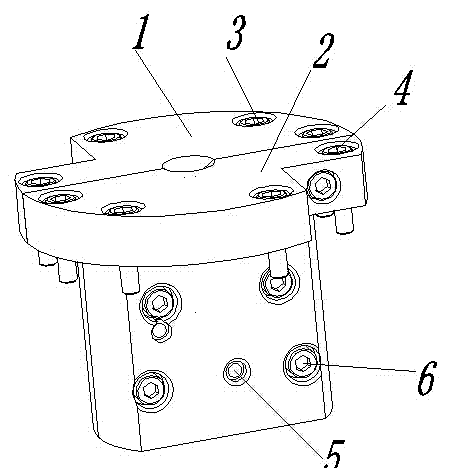

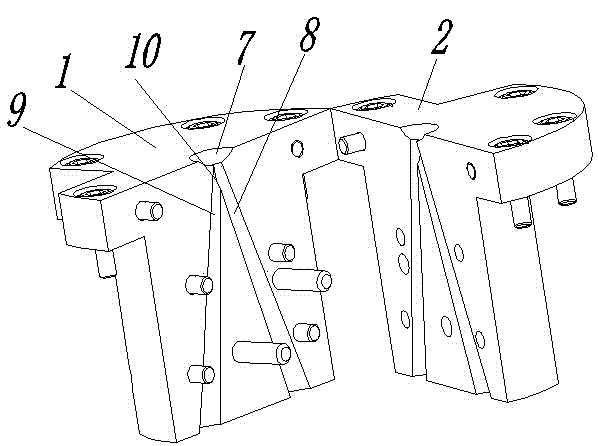

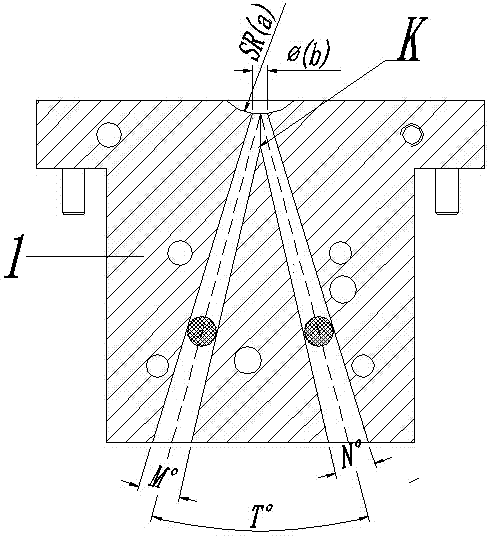

[0012] Figure 1-3 Shown is the relevant explanatory drawing of the present invention;

[0013] A biconical sprue gate bushing, comprising a first runner piece 1, a second runner piece 2, a first piece screw 3, a second piece screw 4, a positioning pin 5, and a plywood fastening Screw 6 spherical nozzle surface 7, first conical main runner 8, second conical main runner 9, injection inlet 10, such as figure 1 , figure 2 shown.

[0014] The sprue bushing is composed of the first runner piece 1 and the second runner piece 2 through the installation and combination of the plywood fastening screw 6 and the positioning pin 5, and is connected by the first piece screw 3 and the second piece screw. 4 Install on the required sprue bushing mold.

[0015] The unilateral composition of the runner on the first runner block 1 of the sprue bushing is composed of the first conical main runner 8, the second conical main runner 9, and the injection molding inlet 10. The spherical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com