Preparation device of steel-plastic composite pipe provided with stainless steel bushing

The technology of a steel-plastic composite pipe and a preparation device, which is applied in the field of pipe manufacturing, can solve the problems of complex equipment, inconsistent force and high cost, and achieve the effects of simple structure of the preparation device, simple structure of the device and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

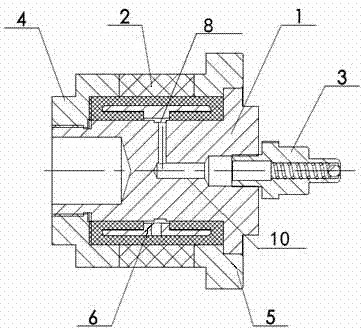

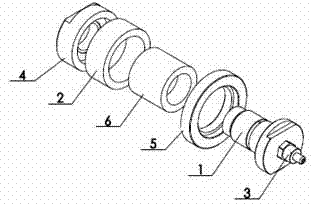

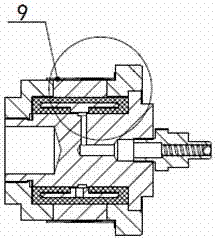

[0020] Such as figure 1 with figure 2 As shown, a preparation device for a steel-plastic composite pipe equipped with a stainless steel bushing includes an oil supply device and an expansion device 7. The expansion device 7 includes an oil pipe joint 3, an expansion drum core 6, and an expansion device embedded in the expansion drum core. The oil-passing mold core 1 in 6, the polyurethane elastic rubber ring 2 set on the expansion drum core 6, the pipe positioning ring set on the end of the oil-passing mold core 1 close to the oil pipe joint 3 and installed on the pass through the thread The compression sleeve on the end of the oil mold core 1 away from the oil pipe joint 3, the oil pipe joint 3 is connected with the output joint of the oil supply device during operation, and the oil supply for the expansion drum core is provided inside the oil mold core 1. An oil passage 10, the input end of the oil supply passage 10 is connected to the oil pipe joint 3, and the output end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com