Preparation method of modified bio-charcoal based catalyst

A biochar and catalyst technology, which is applied in the field of preparation of modified biochar-based catalysts, can solve problems such as unreported process methods, and achieve the effects of simple operation, high removal efficiency and good removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

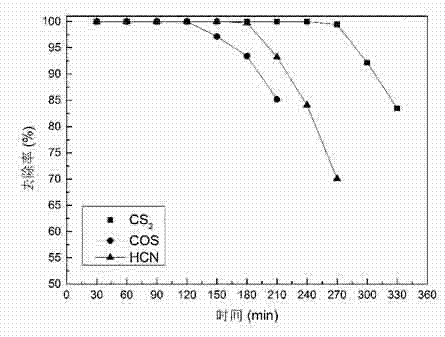

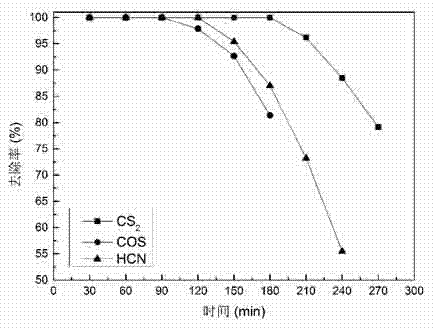

Embodiment 1

[0030]Example 1: Carbonize the tobacco rod under the protection of nitrogen in a tube furnace at 600°C for 1 hour, then mix the carbonized material and KOH evenly in a mass ratio of 1:1, and then carbonize the rod in a tube furnace at 600°C under the protection of nitrogen Activate for 2 hours, take out the activated material and wash with distilled water until the pH is neutral, dry at 120°C for 4 hours to obtain biochar, grind and sieve the biochar into 40-60 mesh, then wash 4 times with water until the supernatant is free of turbidity Suspend and dry in a blast drying oven at 100°C for 7 hours; boil the dried biochar in a KOH solution with a concentration of 1mol / L for 1.5 hours, then wash with distilled water until the pH is neutral, and filter it at 100 Dry in a blast drying oven at ℃ for 7 hours; add the dried biochar to a metal salt solution with a mass percentage concentration of 15% (ferric nitrate 40%, ferrous sulfate 15%, aluminum sulfate 45% and mix to prepare an aq...

Embodiment 2

[0032] Example 2 : The peanut shells were carbonized in a tube furnace at 700°C under the protection of nitrogen for 2 hours, then the carbonized material and KOH were mixed evenly in a mass ratio of 1:2, and activated in a tube furnace at 700°C under the protection of nitrogen for 1 hour. Take out the activated material and wash it with distilled water until the pH is neutral, dry at 110°C for 5 hours to obtain biochar, grind the biochar and sieve it into 40-60 mesh, then wash it with water for 5 times until the supernatant has no turbid suspension, and dry it at 130°C Dry in a blast drying oven at ℃ for 6 hours; boil the dried biochar in a KOH solution with a concentration of 0.9mol / L for 2.0 hours, then wash with distilled water until the pH is constant, filter and place in a blast at 130°C Dry in a drying oven for 6 hours; add the dried biochar to a solution of metal salts (45% ferric nitrate, 20% ferrous sulfate, and 35% aluminum sulfate to prepare an aqueous solution) w...

Embodiment 3

[0034] Example 3 : Coconut shells were carbonized in a tube furnace at 500°C under the protection of nitrogen for 2 hours, and then the carbonized material and KOH were mixed evenly in a mass ratio of 1:3, and activated under the protection of nitrogen in a tube furnace at 600°C for 1 hour. The activated material was taken out and washed with distilled water until the pH was neutral, and dried at 130°C for 7 hours to obtain biochar. The biochar was ground and sieved into 40-60 meshes, then washed 6 times with water until the supernatant was free of turbidity suspended, and dried at 110°C. Dry in a blast drying oven at ℃ for 4 hours; boil the dried biochar in a KOH solution with a concentration of 1.1mol / L for 2.0 hours, then wash with distilled water until the pH is constant, filter and place in a blast at 110°C Dry in a drying oven for 4 hours; add the dried biochar to a metal salt (45% ferric nitrate, 15% ferrous sulfate, and 40% aluminum sulfate to prepare an aqueous soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com