Horizontal impingement flow air-water separator

A technology of water separator and gas flow, which is applied in the field of energy and chemical technology research, can solve the problems of poor separation effect, large tank area, increased flow resistance, etc., and achieves convenient transportation and arrangement of equipment, saving space and Covering an area and reducing the effect of gas-liquid fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

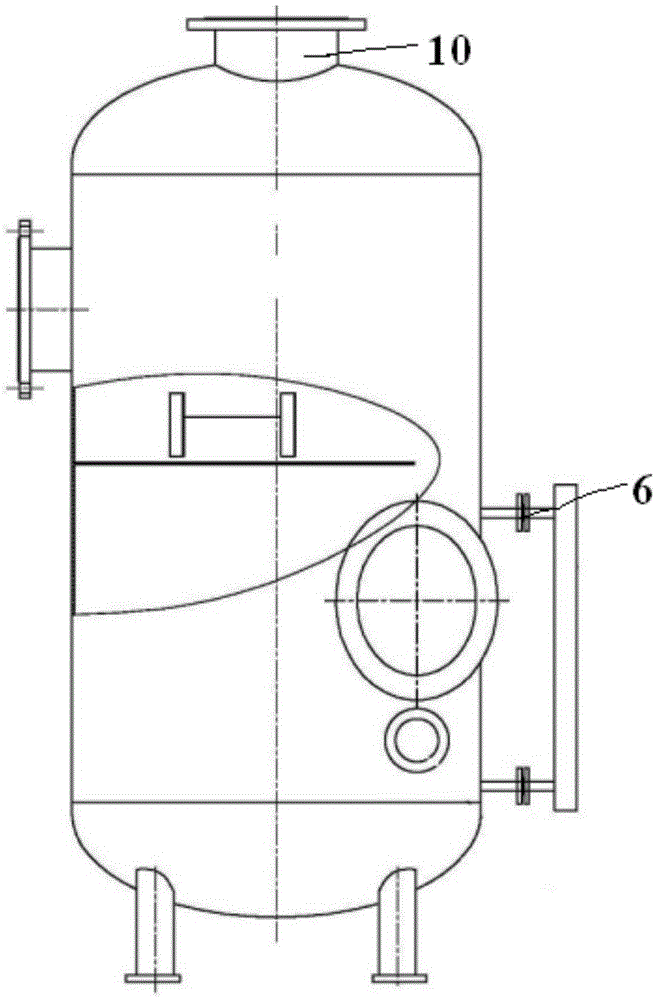

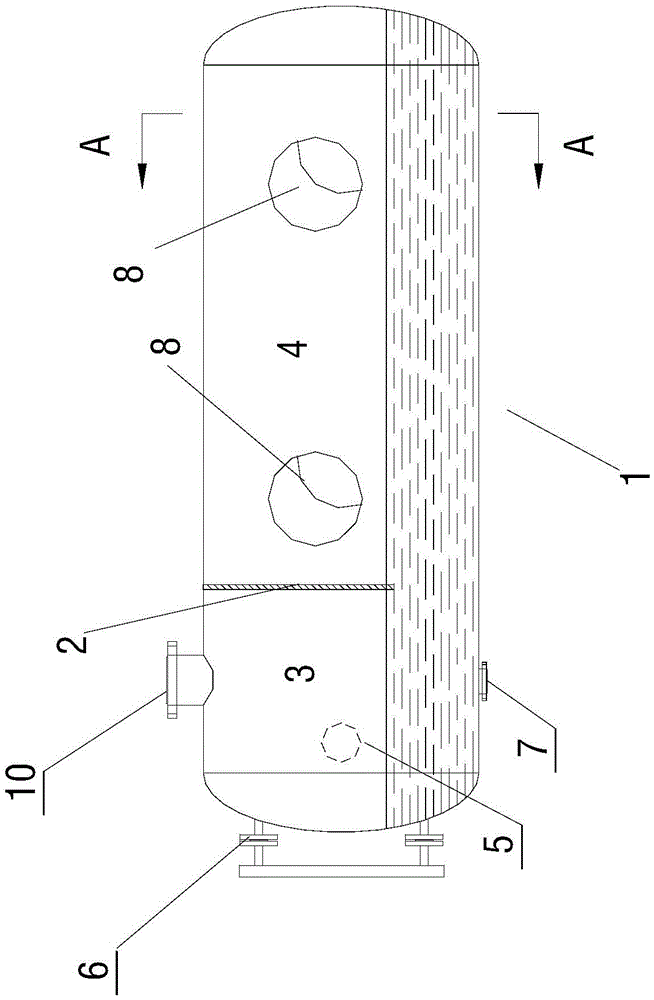

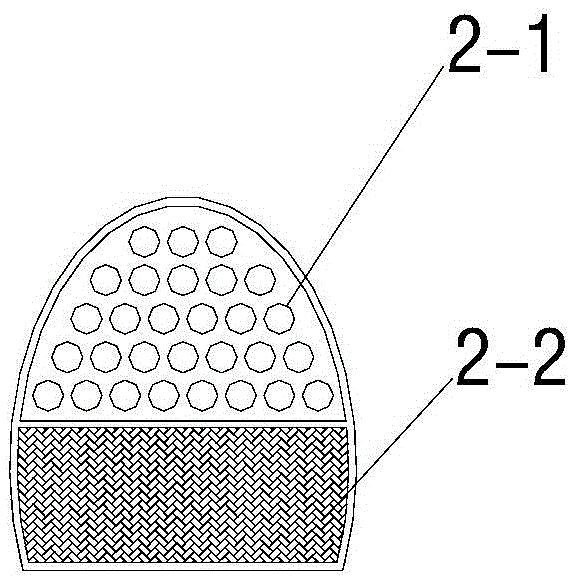

[0015] The following describes the implementation of the present invention in detail with reference to the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples; at the same time, the advantages of the present invention will become clearer and easier to understand through the description.

[0016] Reference figure 1 Shown: When the gas-liquid two-phase flow enters the tank body in the traditional vertical steam-water separator, the kinetic energy cannot be offset, and the impact on the tank body is greater. After the gas-liquid separation, the bottom outlet of the liquid tank body flows out. To prevent the lower liquid from splashing, part The separation tank is equipped with baffles. However, in the actual operation process, the traditionally designed separation tank has problems such as large area, difficult integration, easy splashing of liquid on the top, large liquid level fluctuations, and large deviations in the level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com