Method and device for efficient ventilation of lower part of compound fertilizer granulating tower

A ventilation method and compound fertilizer technology, which are applied to fertilization devices, fertilizer forms, fertilizer mixtures, etc., can solve the problems of insufficient ventilation in the lower part, easy flushing of fertilizers, affecting product yield and quality, etc., achieving small wind resistance and difficult flushing. The effect of output and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

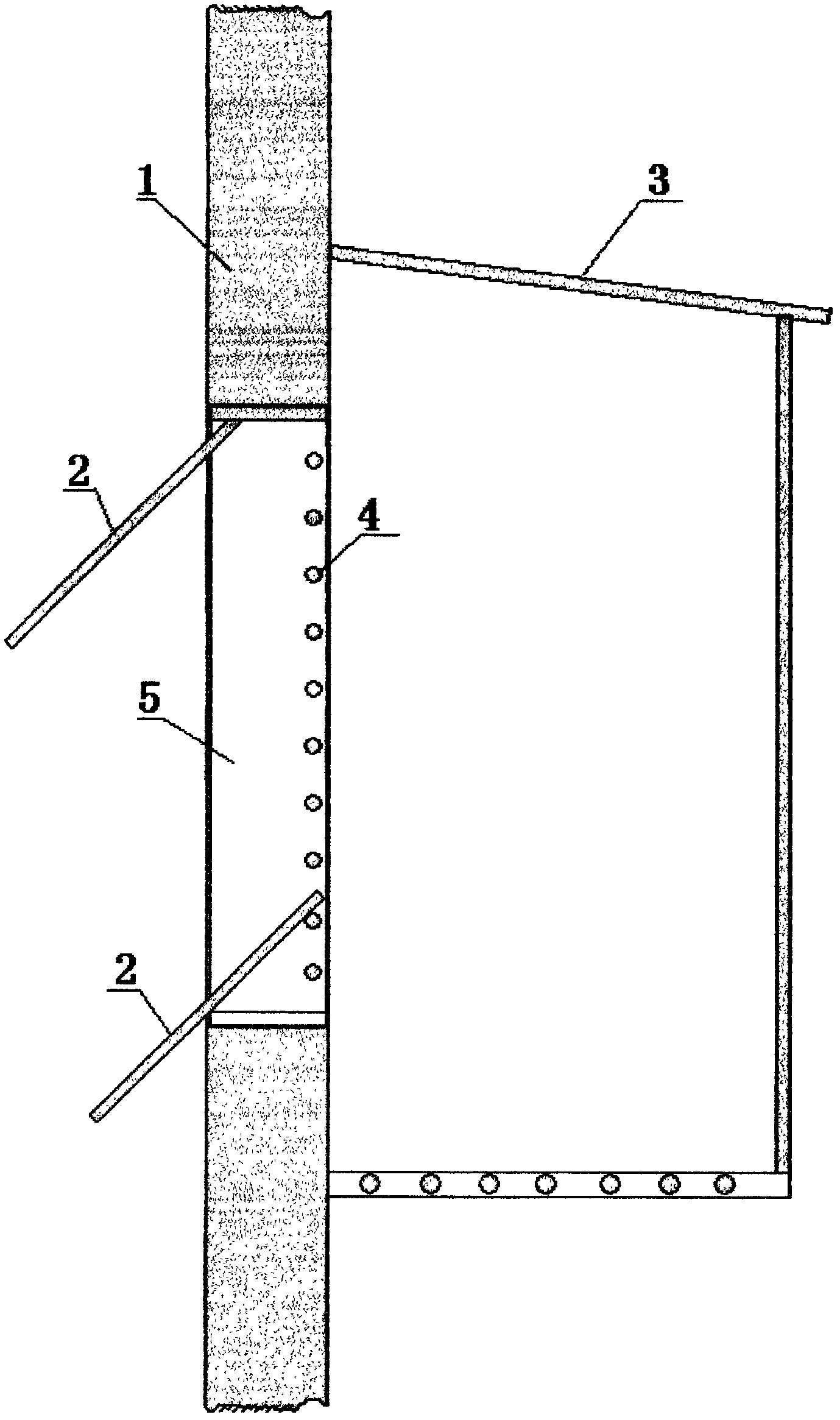

[0025] Embodiment one, such as figure 1 As shown, the device for implementing the method of the present invention is to set a lower vent on the side wall of the lower part of the granulation high tower 1, and the top and bottom of the lower vent are provided with an upper floor that extends toward the inside of the tower. The baffle plate 2 and the lower floor slant the baffle plate 2 to prevent the compound fertilizer grain falling downwards from being thrown outside the air vent; prevent rainwater from entering the air vent by arranging a rain-proof awning 3 outside the lower part of the air vent. The rain-proof awning 3 extends around the lower vent, and the top has a rain-proof awning that is sealed and fixed with the outer wall of the granulation high tower above the lower vent, and the bottom has a granulation height below the lower vent. The ventilation fence seat fixed on the outer wall of the tower, the vertical rain shield is fixed between the rain shield and the ven...

Embodiment 2

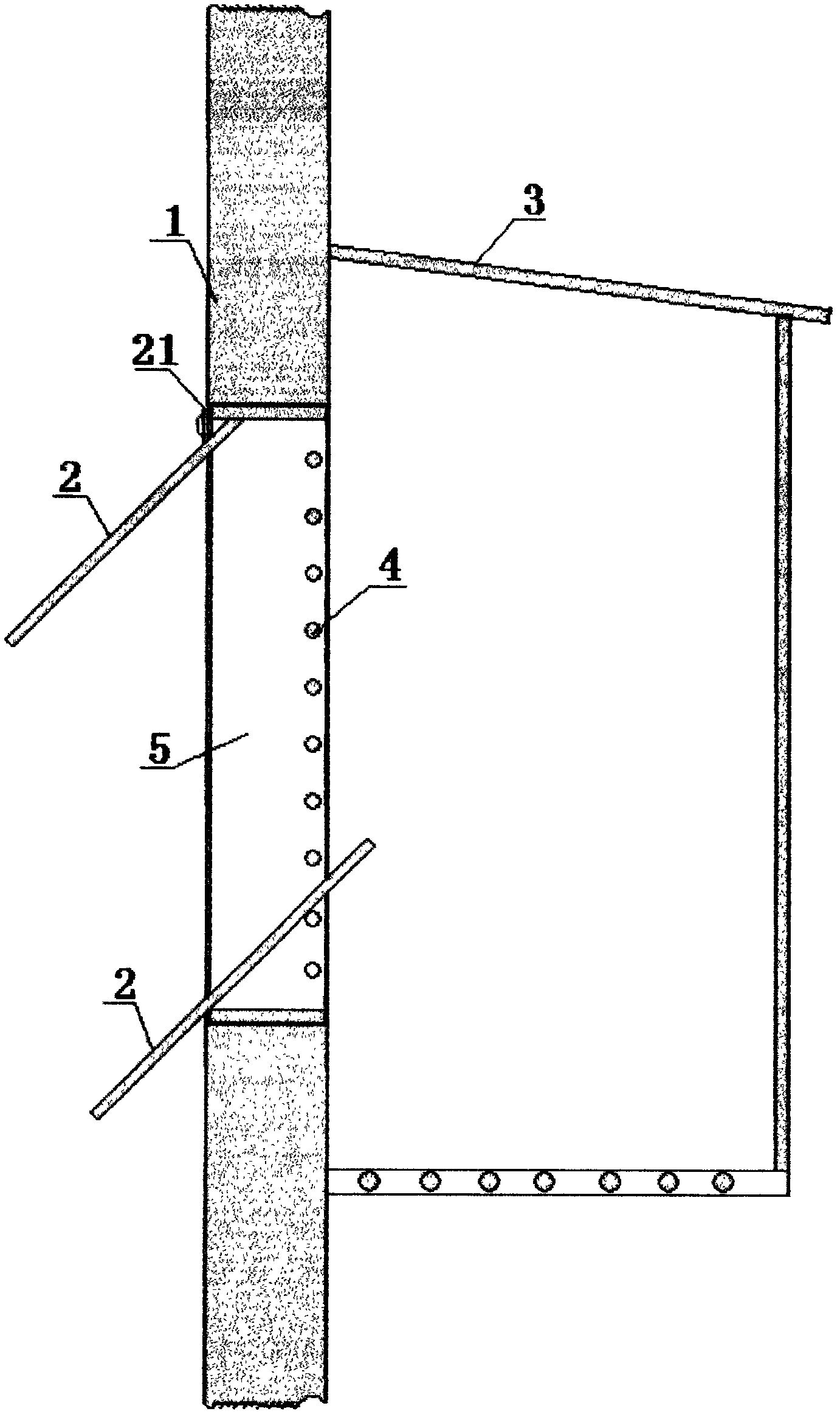

[0027] Embodiment two, such as figure 2 As shown, the difference between the device for implementing the method of the present invention and the first embodiment is that the upper downward slope baffle plate 2 extends to the inner wall of the high granulation tower 1 on both sides. Preferably, it extends in a semicircle with the angle between the upper downslope baffle plate 2 and the inner wall of the tower as the center of the circle. The tower inner wall end of the extension part 21 further extends upward along the tower inner wall and is fixed together with the tower inner wall. And the lower sloping baffle 2 extends outwards to the outside of the lower vent.

Embodiment 3

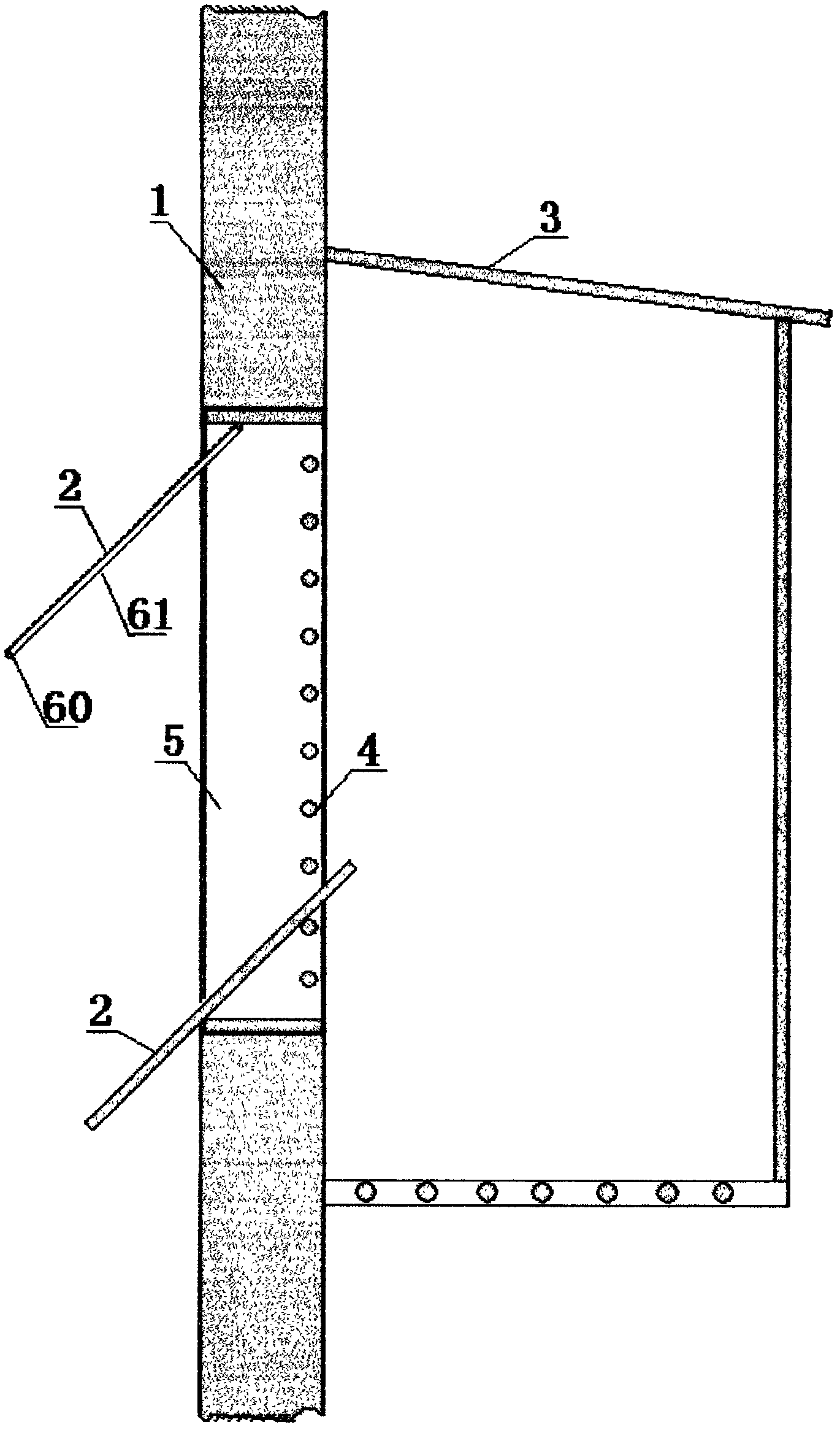

[0028] Embodiment three, such as image 3 As shown, the difference between the device for implementing the method of the present invention and Embodiment 1 is that: the upper sloping baffle plate 2 adopts a sieve plate with holes smaller than the particle size of the compound fertilizer; and the sieve plate is equipped with a surrounding frame 60 And the frame that vertical support bar 61 forms. And the lower sloping baffle plate 2 also extends outwards to the outside of the lower vent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com