Device for sorting tobacco stems before shredding and using method thereof

A technology for trimming stems and tobacco stems, which is applied to the field of trimming devices for cutting tobacco stems, can solve the problems of clogging, excessively long cut stems, poor blending uniformity, etc., and achieves good blending uniformity and reasonable structure of cut stems. , the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: the stem-trimming device of the present invention

[0052] The stemming device of this embodiment is described as follows:

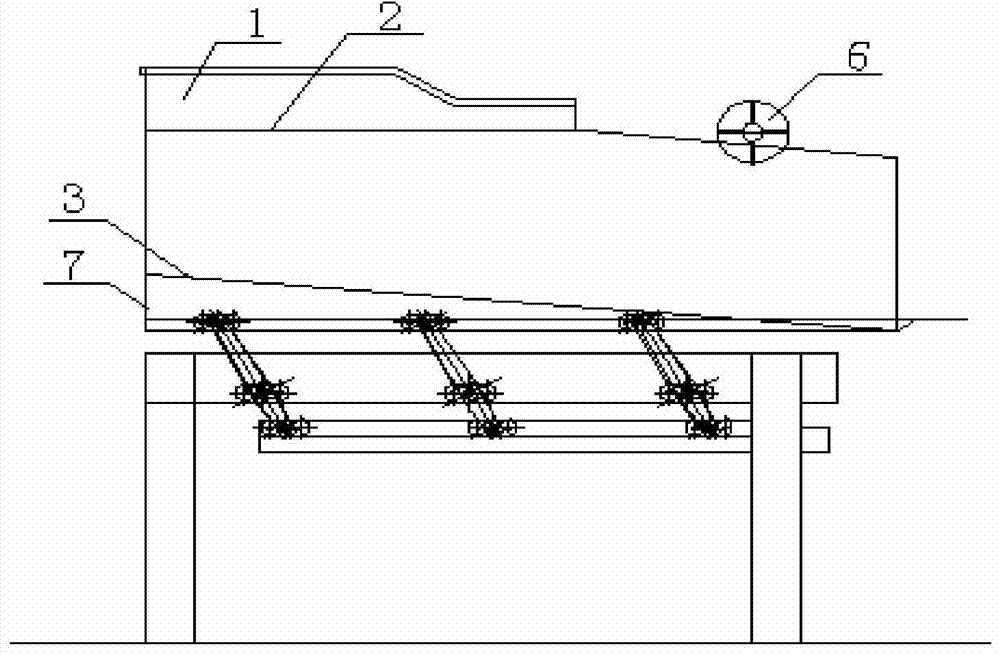

[0053] The stem trimming device is composed of a vibrating hopper 1, a stem trimming sieve plate 2, a longitudinal separation plate 4, a material level control system 6 and a vibration tank body 7 of the stem trimming machine.

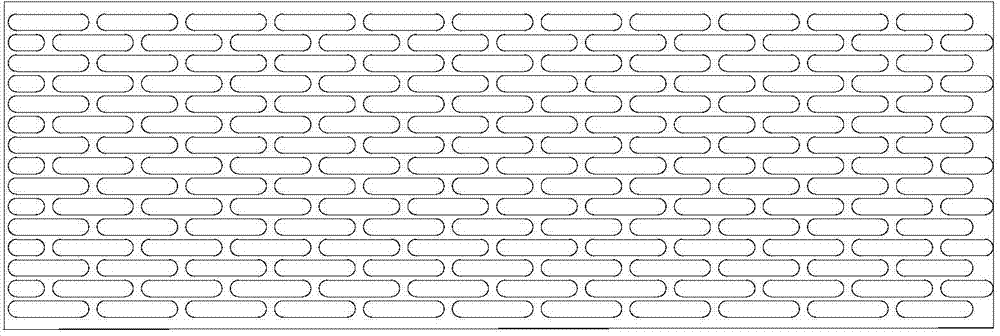

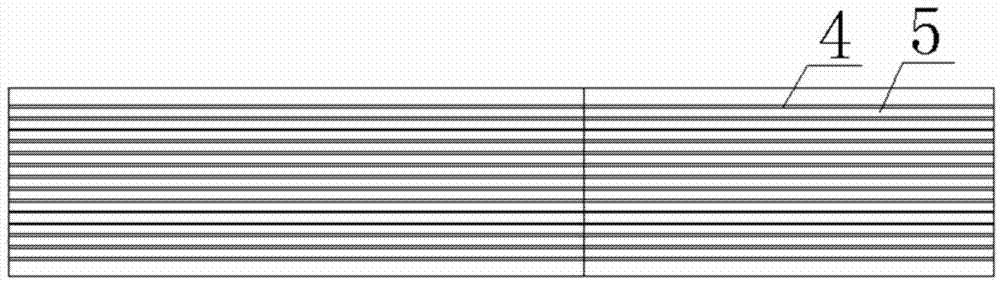

[0054] The vibrating hopper 1 is located on the top of the vibrating tank 7 of the stemming machine, and the bottom of the vibrating hopper 1 is the stemming sieve plate 2; the whole stemming sieve plate 2 is evenly distributed with rectangular sieve holes, and the opening of the stemming sieve plate 2 is rectangular. The porosity is 55%, the length of the rectangular sieve hole is 10% of the length of the sieve plate 2, and the width of the rectangular sieve hole is 2% of the width of the sieve plate 2 of the stalk. The longitudinal axis direction of the rectangular screen hole is parallel to the longitudin...

Embodiment 2

[0059] Embodiment 2: stem-trimming device of the present invention

[0060] The stemming device of this embodiment is described as follows:

[0061] The structure of the stemming device in this embodiment is the same as that of Example 1, except that the opening rate of the sieve plate 2 for stalking is 90%, and the length of the rectangular sieve is 15% of the length of the sieve plate 2 for stalking. The width of the rectangular sieve hole is 4% of the width of the stem sieve plate 2; the angle α between the material conveying direction in the longitudinal guide groove 5 and the material conveying direction of the copper bar chain at the bottom of the shredder is 60°; The angle β between the bottom of the vibrating tank 7 and the horizontal plane is 7°; the vibration frequency of the vibrating hopper 1 and the vibrating tank 7 of the stem trimmer is 5 times per second, and the vibration amplitude is 3.0 cm.

[0062] The effect of the shredded stems cut out by the stem-trimm...

Embodiment 3

[0063] Embodiment 3: the stem-trimming device of the present invention

[0064] The stemming device of this embodiment is described as follows:

[0065] The structure of the stemming device in this embodiment is the same as that of Example 1, except that the opening rate of the 2 rectangular screen holes of the sieve plate 2 is 40%, and the length of the rectangular sieve hole is 5% of the length of the sieve plate 2. The width of the rectangular sieve hole is 10% of the width of the sieve plate 2; the angle α between the material conveying direction in the longitudinal guide groove 5 and the material conveying direction of the copper bar chain at the bottom of the shredder is 0°; The angle β between the bottom of the vibrating tank body 7 and the horizontal plane is 3°; the vibration frequency of the vibrating hopper 1 and the vibrating tank body 7 of the stem trimmer is 10 times per second, and its vibration amplitude is 0.5 cm.

[0066] The effect of shredded stems cut out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com