Device and method for automatic assembly of photovoltaic panels

An automatic assembly, photovoltaic panel technology, applied in photovoltaic power generation, electrical components, climate sustainability, etc., can solve the problems of lack of BCBS, commercial proliferation of BC panels has not yet appeared, lack of machines or devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In the subsequent examples of embodiment, each feature given with respect to a particular example may in fact be interchanged with other different features present in other examples of embodiment.

[0060] Also, it should be noted that any known matter discovered during the patent application process is understood to be unclaimed and the subject of a disclaimer.

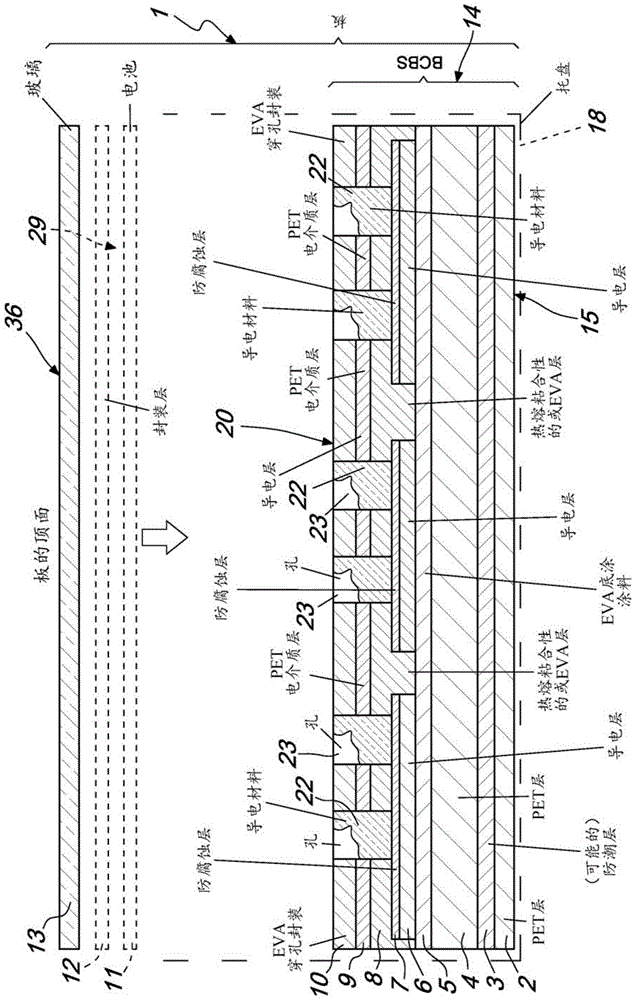

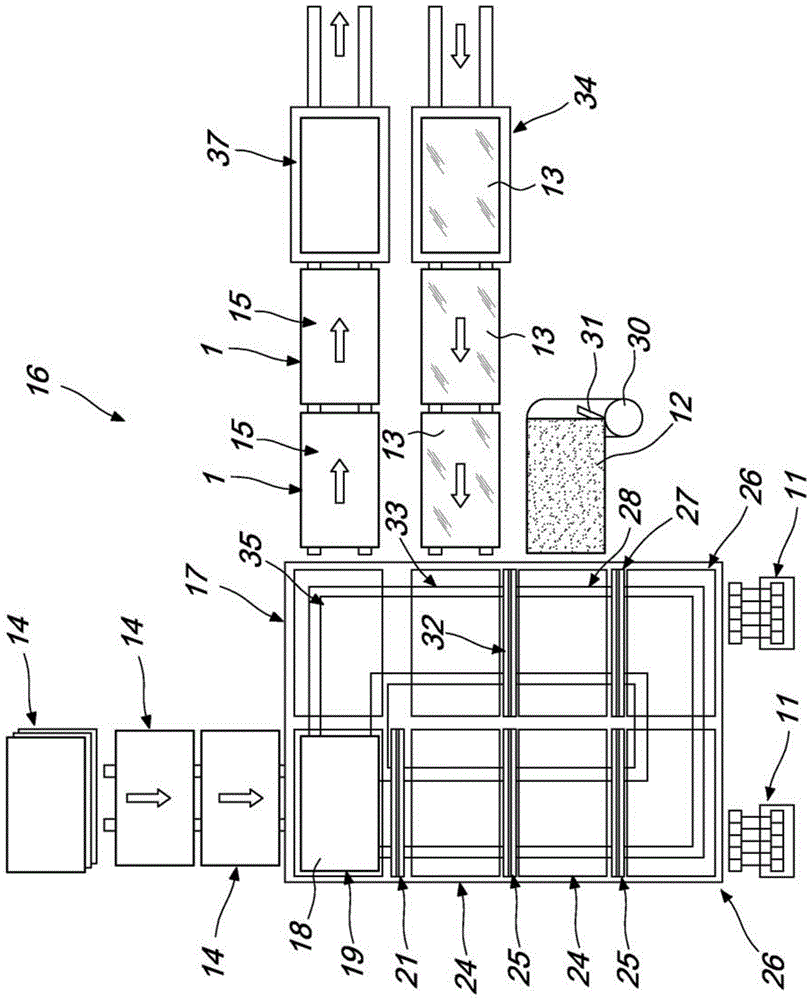

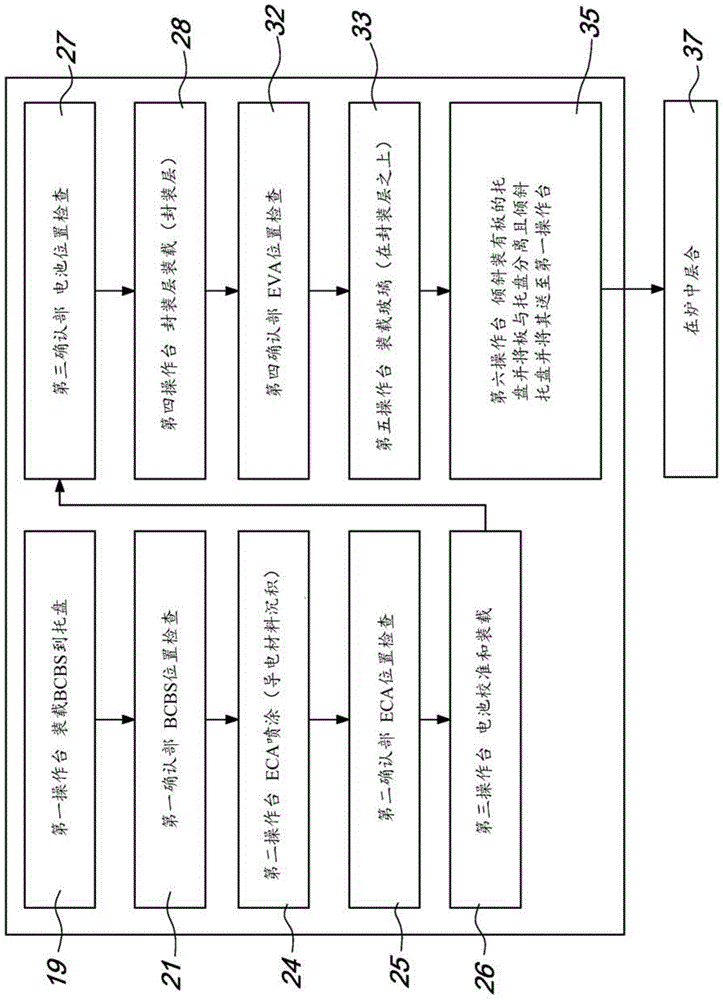

[0061] According to the figures cited above, reference numeral 1 designates a photovoltaic panel with a back contact structure comprising a back layer 2 made of PET, an optional moisture barrier 3, an additional layer 4 made of PET, a Primer layer 5 made of EVA, conductive layer 6, anti-corrosion layer 7, thermoadhesive or layer 8 made of EVA, dielectric layer 9 such as made of PET , hot-melt adhesive or perforated encapsulation element 10 made of EVA.

[0062] Photovoltaic panel 1 also includes cells 11 , encapsulation layer 12 and glass 13 .

[0063] The numeral 14 designates the BCBS and thus the element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com