Oil seal

A technology for oil seals and sealing parts, which is used in engine components, engine seals, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

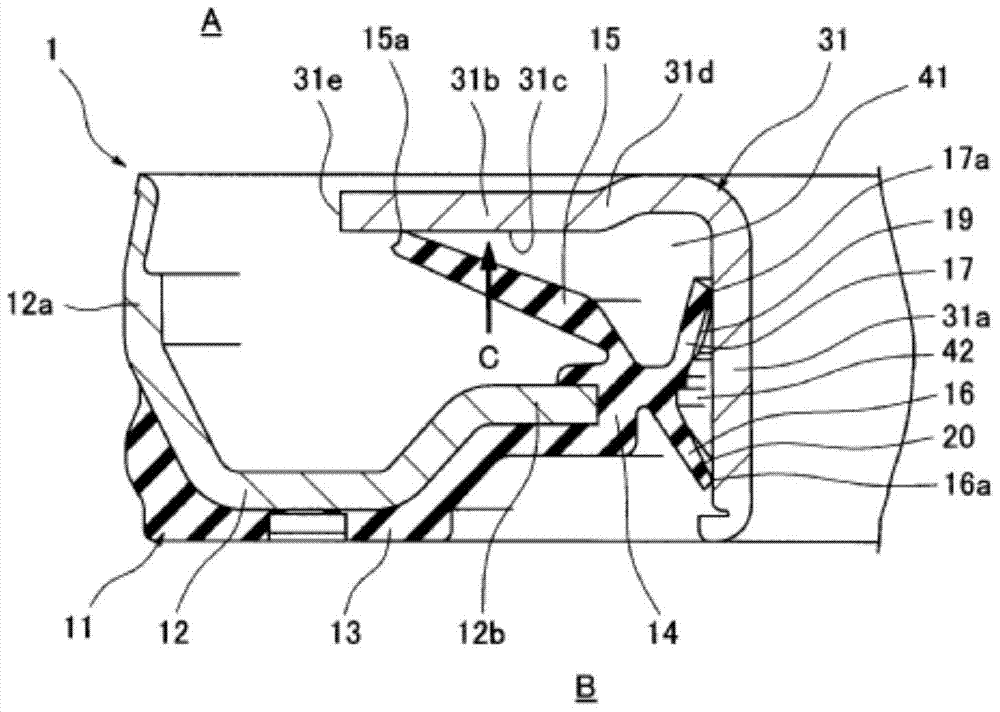

[0058]Next, embodiments of the present invention will be described based on the drawings.

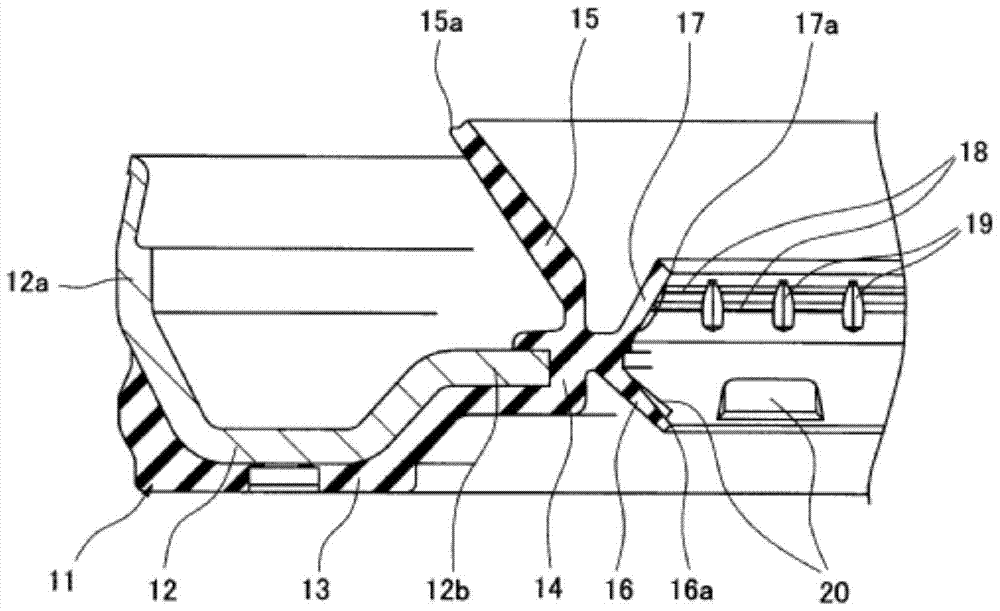

[0059] figure 1 A main part cross section of the oil seal 1 according to the embodiment of the present invention is shown, figure 2 The state before combining the lip seal member 11 and the flinger 31 in the same oil seal 1 is shown.

[0060] figure 1 The oil seal 1 shown in is composed of a lip seal member 11 fixed to the inner periphery of a shaft hole of a casing (not shown), and an oil flinger 31 fixed to a rotating shaft (not shown) inserted through the shaft hole. Combination of these components prevents leakage of sealing fluid from inside A to outside B, and at the same time prevents dust from outside B from entering inside A.

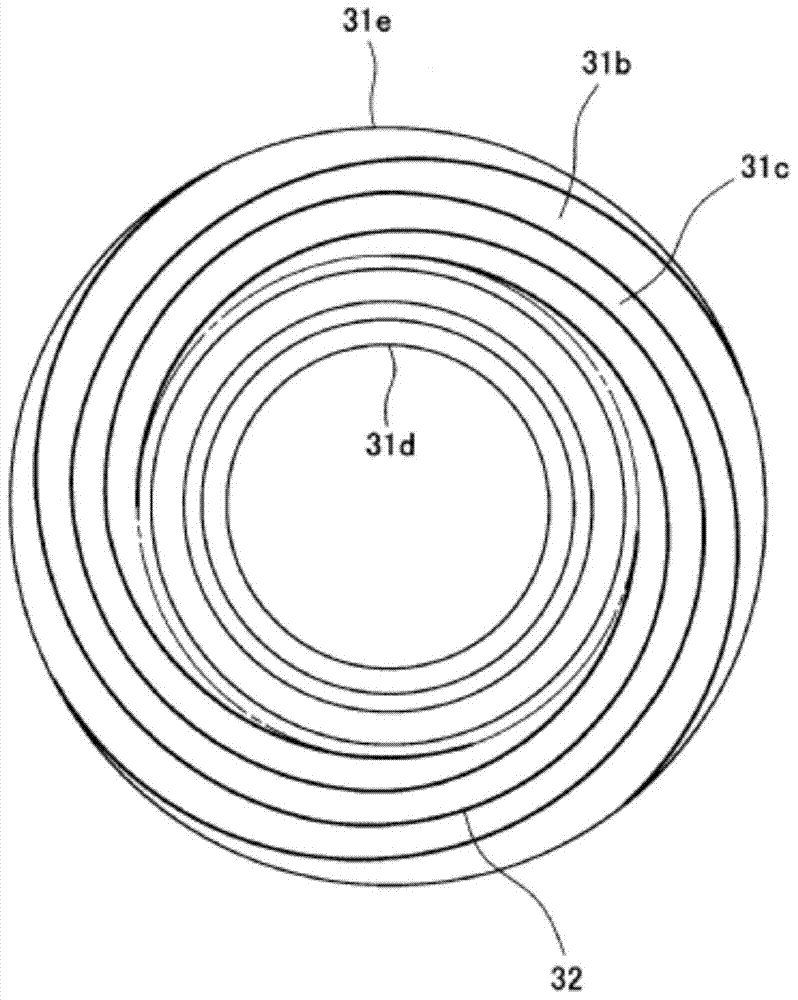

[0061] The oil flinger 31 is made of a metal material, and a flange portion 31b is integrally formed radially outward at the machine inner end portion of the cylindrical portion 31a fitted on the outer peripheral surface of the rotating shaft, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com