Method and circuit arrangement for determining a working range of an ultrasonic vibrating unit

A technology of vibration mechanism and working range, which is applied in the direction of using vibration fluid, measuring electricity, manufacturing tools, etc., and can solve the problems of operator danger, inability to work, high sound intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

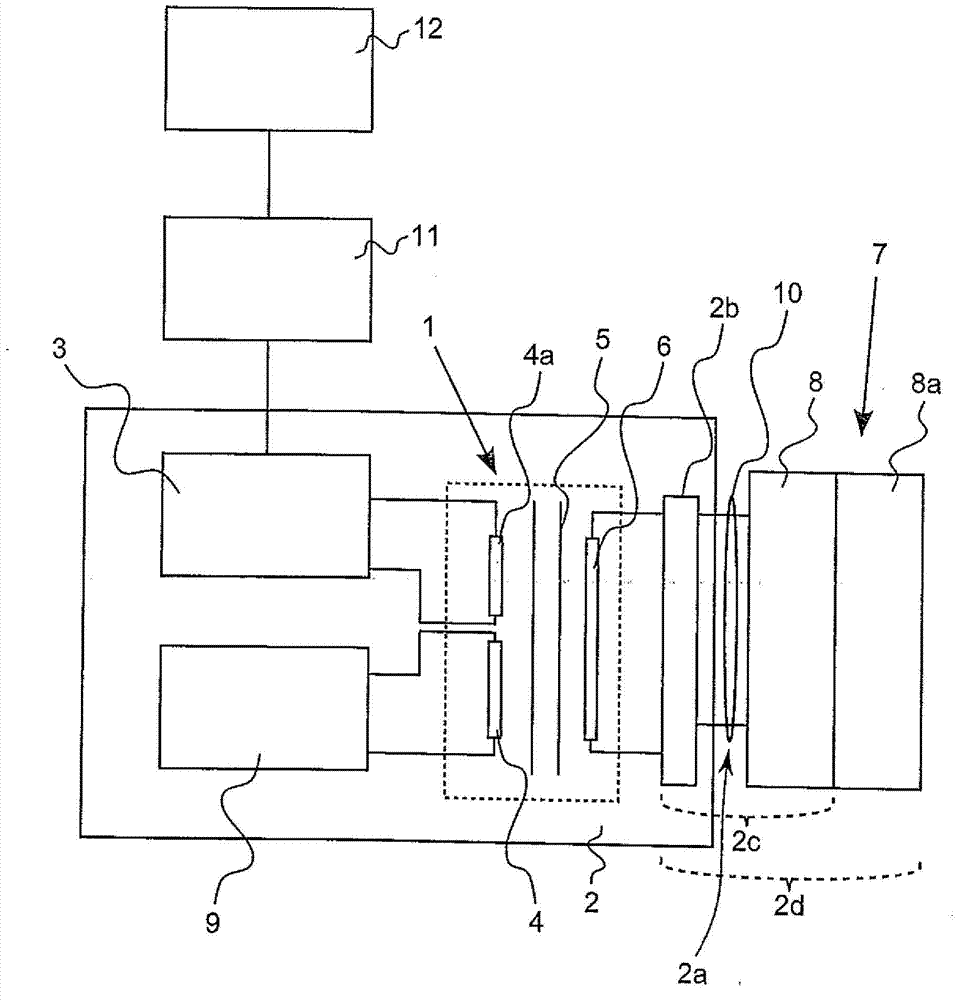

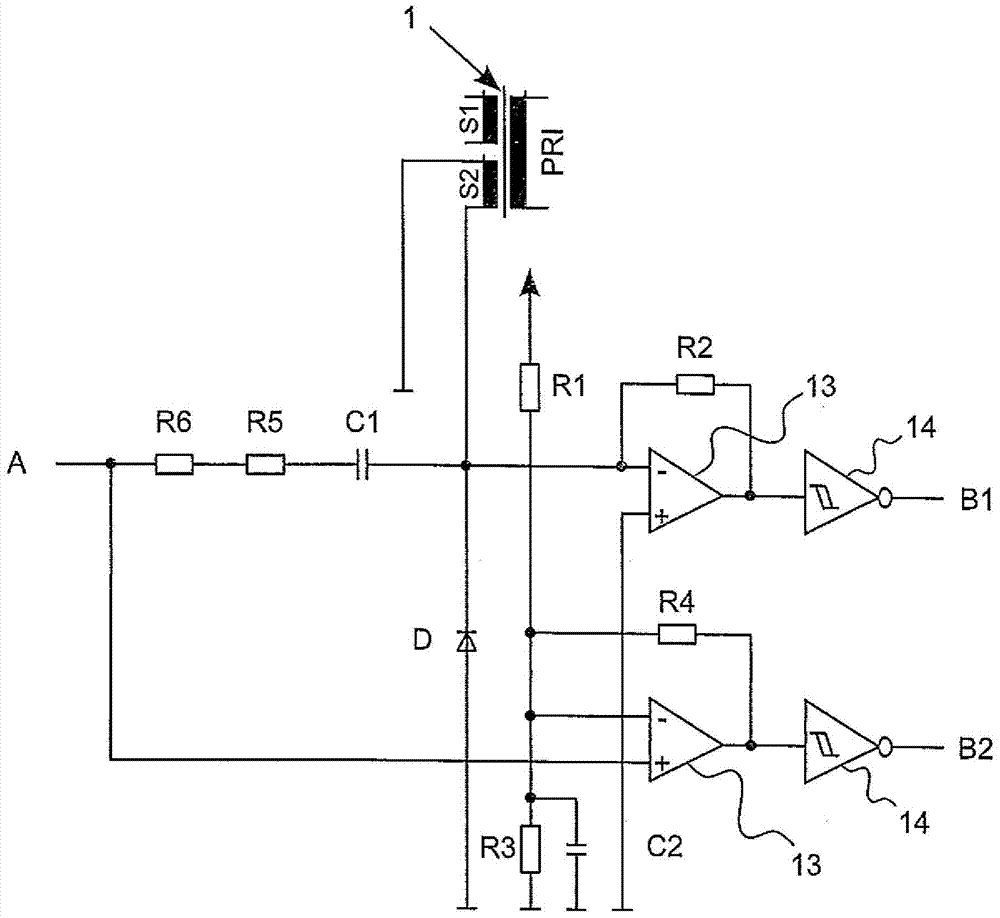

[0032] figure 1 The equivalent circuit diagram of an ultrasonic vibration system is shown in FIG. 1 , which according to one embodiment of the invention has a transformer 1 (dashed box) which is arranged inside a (ultrasonic) generator 2 . This transformer 1 is also connected to a measuring circuit 3 . The primary-side transformer winding 4 is operatively connected via a ferrite core 5 to an inductance (secondary-side transformer winding) 6 , wherein the transformer 1 also has an additional primary-side auxiliary winding 4a in the exemplary embodiment shown. .

[0033] The inductance 6 is electrically connected on the secondary side of the transformer 1 to an ultrasonic transducer 8 which is connected by means of a cable 10 to the output 2 a of the generator 2 and is connected to the usual presence of the inductance 6 and the generator 2 The matching network 2b together forms an electrical resonant circuit 2c. The ultrasonic transducer 8 , for example a piezo transducer, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com