Sunscreen cosmetic

A technology for cosmetics and emulsified cosmetics, used in cosmetics, cosmetic preparations, cosmetic preparations, etc., can solve the problems of limited use of touch, heavy touch, etc., and achieves non-whitening, non-greasy, and excellent water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0073] Hereinafter, examples are given to further specifically describe the present invention, but the present invention is not limited thereto. In addition, unless otherwise specified, the compounding quantity shows the mass % with respect to a total amount.

[0074] The oil phase components of the water-in-oil type sunscreen cosmetics in "Table 1" and the emulsion as water-in-oil emulsified sunscreen cosmetics in "Table 2" were prepared by conventional methods, and water resistance and emulsion stability were evaluated.

[0075] It should be noted that the oil phase components of the water-in-oil emulsified sunscreen cosmetics shown in "Table 1" are formulated by mixing with water phase ingredients by conventional methods to form the oil phase of the water-in-oil emulsified sunscreen cosmetics. Regarding the oil phase components in "Table 1", the water resistance was evaluated.

[0076] "Water Resistance Judgment 1"

[0077] Focusing on the oil phase components in "Table 1...

Embodiment 2

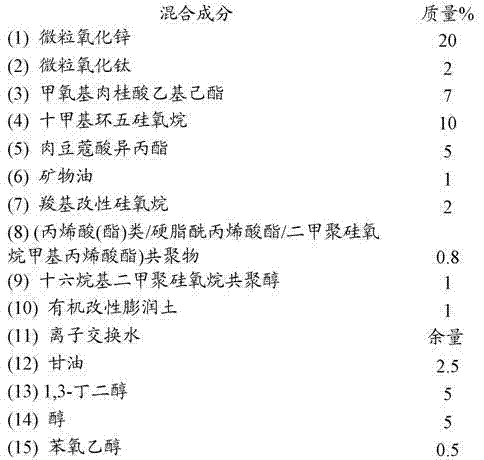

[0104] Example 2: Sunscreen (W / O Cream)

[0105]

[0106] Production method: mixing and dispersing (1) to (10). Thereafter, the water phases of (11) to (15) which were mixed and dissolved were added and mixed to obtain the intended sunscreen.

Embodiment 3

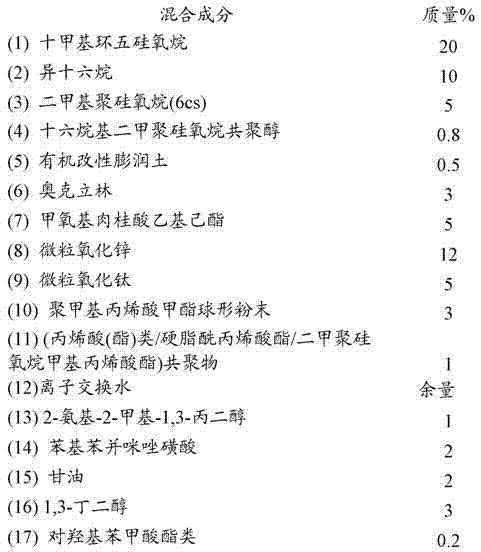

[0107] Embodiment 3: sunscreen lotion (two-layer type W / O emulsion)

[0108]

[0109] Production method: mixing and dispersing (1) to (11). Thereafter, the water phases of (12) to (17) which were mixed and dissolved were added and mixed to obtain the intended sunscreen lotion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com