Spark plug

A spark plug and main body technology, applied in the field of spark plugs, can solve the problems of increasing the output rate of spark plug waste parts, the influence of engine work, and the increase in processing difficulty, so as to achieve convenient measurement and adjustment of ignition gap, high applicability, stability and accuracy high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

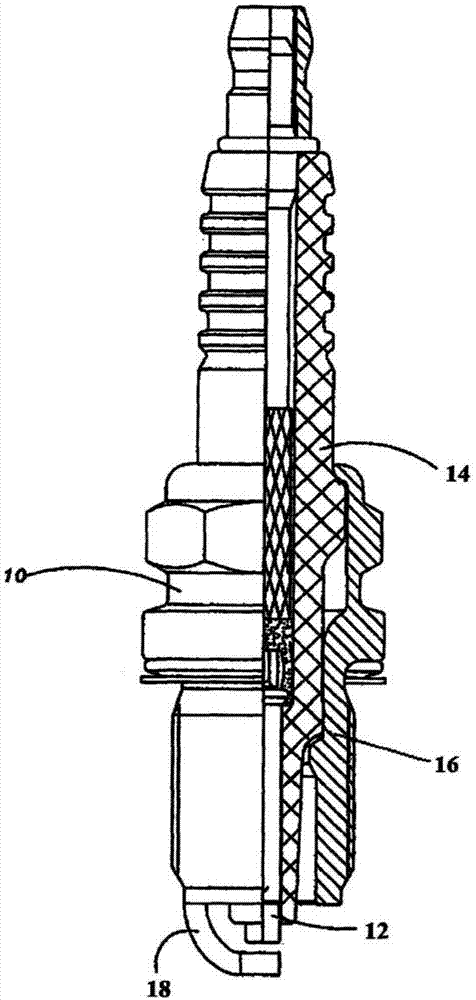

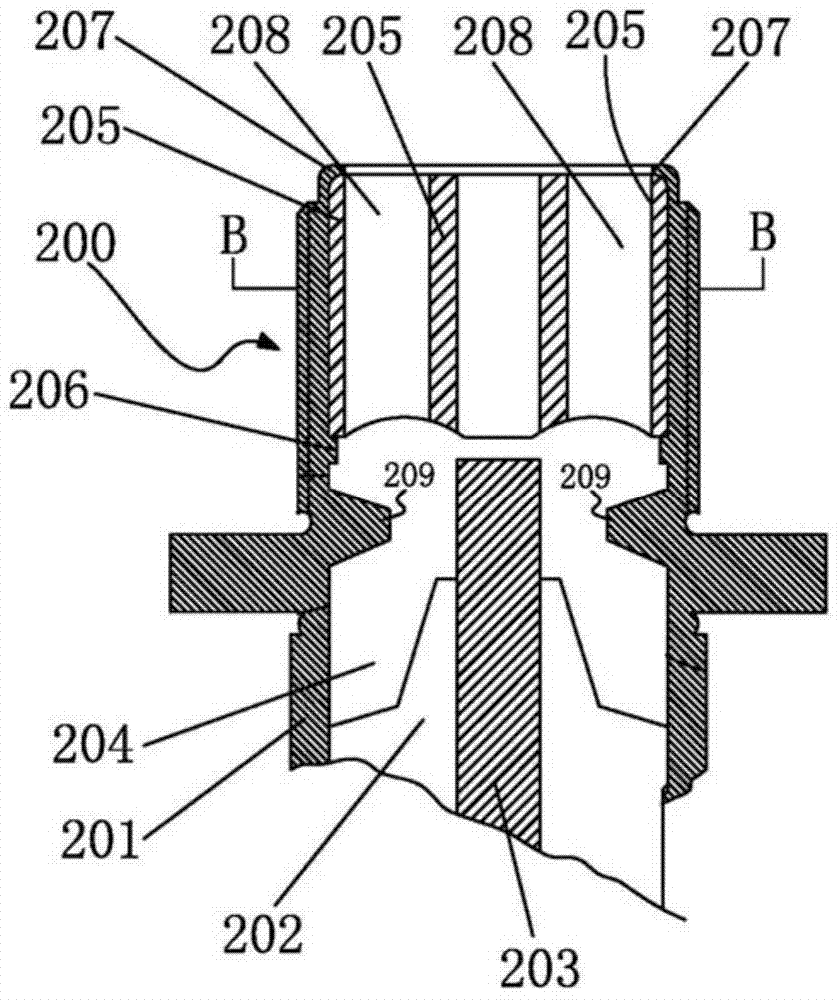

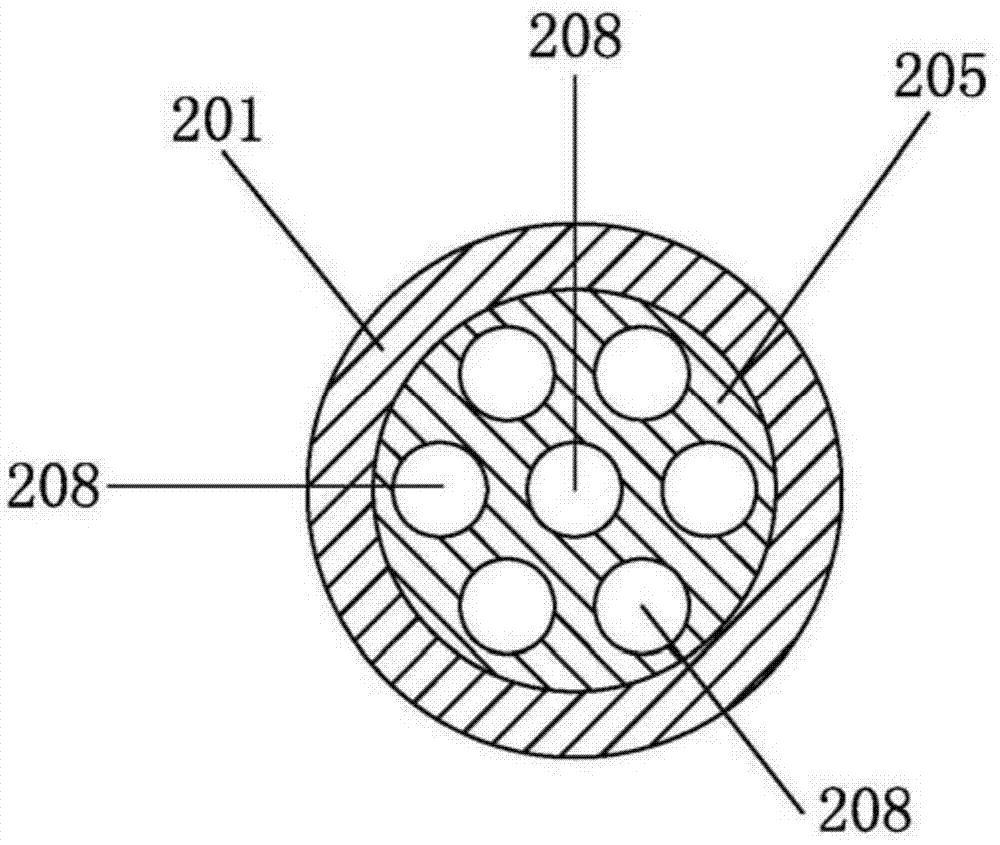

[0048] Please also see Figure 4 and Figure 5 ,in, Figure 4 A schematic diagram of the structure of the spark plug, Figure 4 A partial cross-sectional schematic diagram of the ignition unit 5 is Figure 5 The cross-sectional view of the A-A direction in the middle.

[0049] The spark plug provided by the present invention includes a center electrode 1 , an insulator 2 , a shell 3 , a connecting rod 4 and an ignition unit 5 . The insulator 1 has a shaft hole extending along the axis direction, and the center electrode 1 is inserted into the shaft hole with the end exposed. The casing 3 is a hollow column, sheathed on the surface of the insulator 2, and the end of the center electrode is exposed outside the casing. The ignition unit 5 is located outside the housing 3 and is fixedly connected to the end of the housing 3. It can be connected to the housing 3 through at least one connecting rod 4. In particular, in this embodiment, the ignition unit 5 is connected through two...

Embodiment 2

[0057] Embodiment two of the present invention, refer to Figure 9 and 10 . Figure 9 is a structural schematic diagram of the spark plug, wherein, a partial cross-sectional schematic diagram of the ignition unit 5 is Figure 5 The cross-sectional view of the A-A direction in the middle. Figure 10 is a three-dimensional structure diagram of the ground electrode. Embodiment 2 of the present invention is basically the same as Embodiment 1, except that the center electrode 1 is not inserted into the through hole of the annular sheet 511b, but outside the through hole; meanwhile, the diameter of the through hole is larger than that of the center. The diameter of the electrode is small, therefore, the axial space between the annular sheet 511b and the central electrode 1 acts as an ignition gap; in addition, except for the step 532, the inner wall of the main body 53b forms a conical detonation cavity, which is close to the ground The diameter of the end face of electrode 51 i...

Embodiment 3

[0059] Embodiment three of the present invention, see Figure 11 , which is the front view of the ground electrode. The third embodiment is basically the same as the second embodiment, except that the ground electrode 51c is not provided with an annular sheet 511b and a fixed foot 512, but with a plurality of through holes, the diameter of which is larger than that of the through hole on the baffle plate 52. The diameter is small, so the effect similar to that of the second embodiment can also be achieved, that is, guiding the main airflow to inject towards the direction of the combustion chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com