Coal sample stir-mixing and drying device

A technology of stirring, mixing and drying, which is applied to the field of coal sample stirring, mixing and drying, can solve the problems of lowering work efficiency, cannot use special coal types, and cannot be carried out at the same time, so as to reduce labor intensity, shorten preparation cycle, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

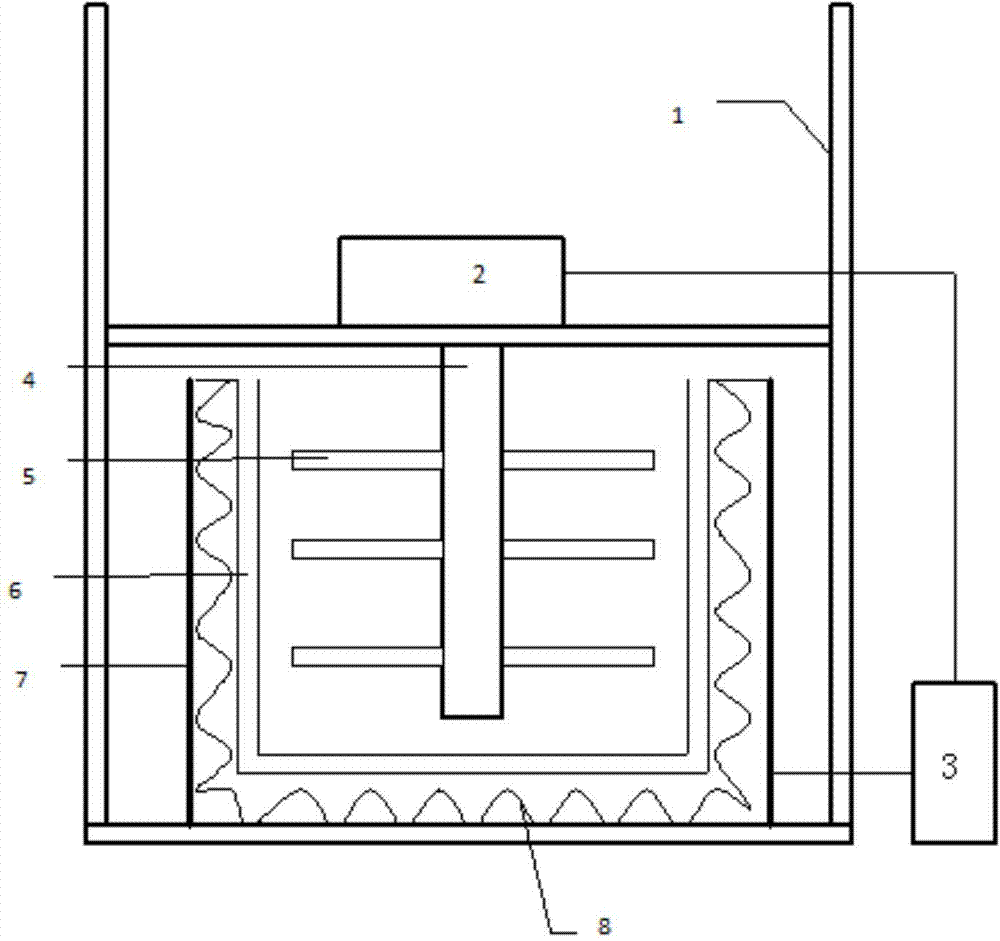

[0025] Such as figure 1 As shown, a coal sample stirring and mixing dryer includes a heating kettle 7, a stirrer (stirring motor 2, stirring shaft 4, and stirring rod 5), a sample cylinder 6, a lifting device 1, and a controller 3.

[0026] The heating kettle 7 is in the shape of a cylinder and is divided into an inner furnace and an outer shell. The space between the inner furnace and the outer shell is composed of a spiral heating element 8 passing through the inner furnace lining. The inner furnace lining is made of silicon carbide refractory material. Sealed structure.

[0027] The stirrer comprises a stirring motor 2, a stirring shaft 4 and a stirring rod 5. The stirring motor 2 is provided with a fixed rod and bidirectionally connected to the lifting rod to facilitate the lifting of the stirrer.

[0028] The sample cylinder 6 is made of stainles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com