A secondary light distribution lens and equipment for discrete LED light sources

A technology of LED light source and lens, applied in the direction of light source, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problem of uneven distribution of light field, which limits the use effect of discrete light source lighting, and can not effectively solve the problem of light spot distribution and influence of light source. Lighting effect and other issues, to achieve the effect of improving light output, excellent spot quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

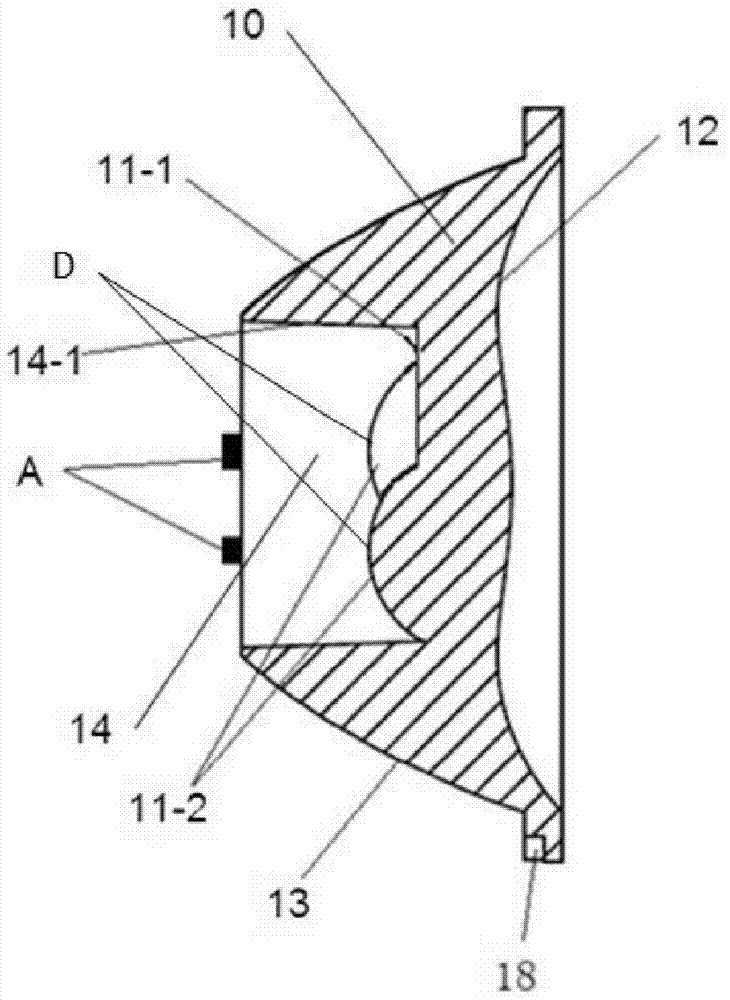

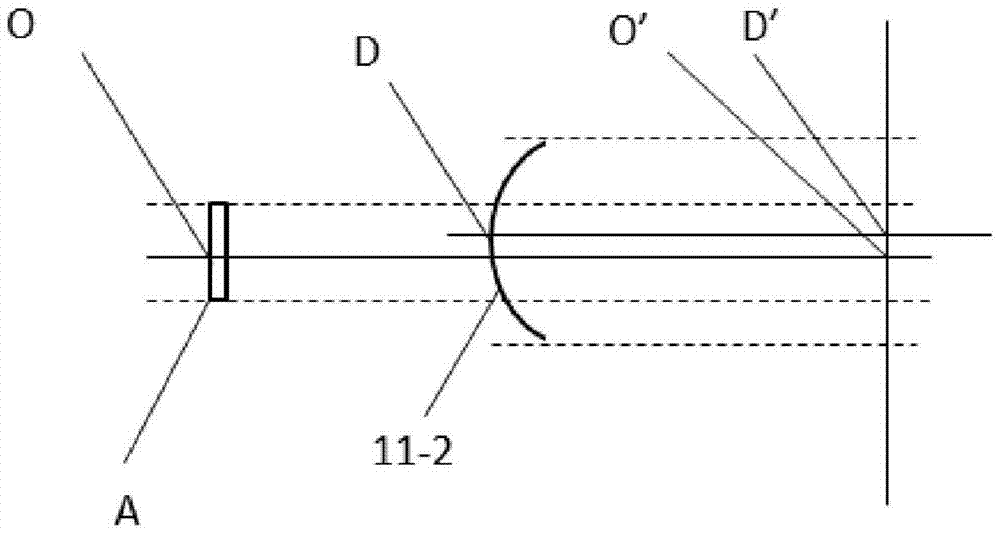

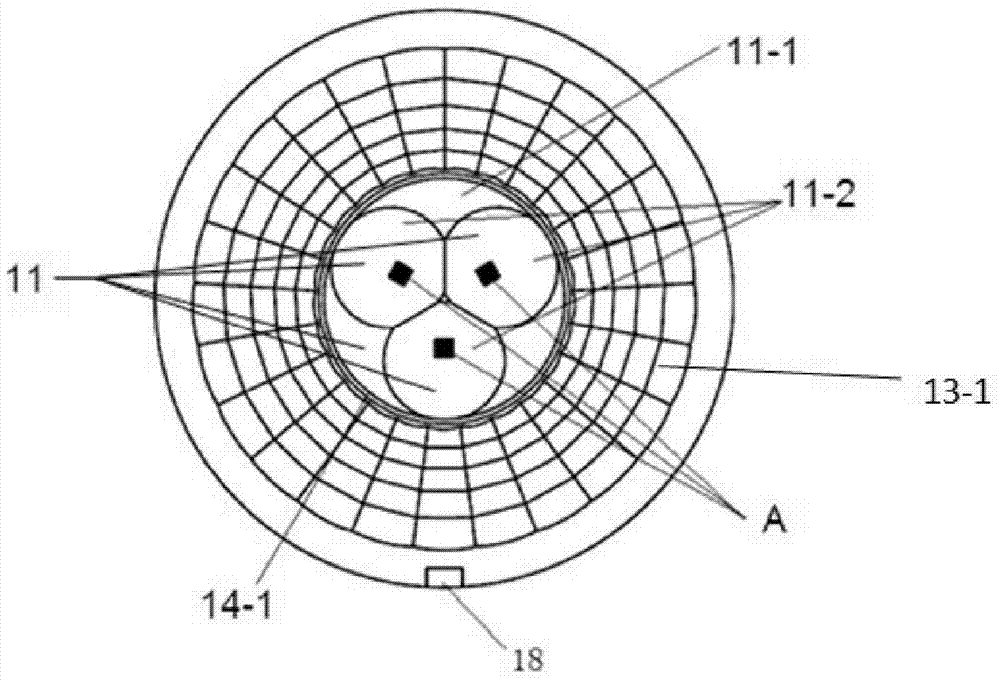

[0052] Such as image 3 As shown, this embodiment includes 3 sub-light sources, of which the 3 sub-light sources are single LED light sources (or LED light sources packaged in a single chip), and the 3 sub-light sources are evenly distributed off-axis relative to the central axis of the lens body. In the implementation, the top end face of the incident hole of the lens is a plane, and on the plane of the top end face, there are sub-incident end faces corresponding to the three sub-light sources, and the sub-incident end faces are spherical; when working, align the three sub-light sources with the corresponding sub-incident end faces The center of the sphere (the off-axis of the three sub-spheres relative to the center axis of rotation on the side of the entrance hole of the lens is the same as the off-axis of the center of the corresponding light source relative to the rotation axis on the side of the entrance hole of the lens). The emitted part of the off-axis light is modula...

Embodiment 2

[0056] Such as Figure 5 As shown, this embodiment includes 3 sub-light source modules, wherein the 3 sub-light source modules respectively include 3 secondary sub-LED light sources arranged in a zigzag shape or 3 single LED light sources packaged in a sub-chip arranged in a zigzag shape ( Figure 4 The small dotted line box indicates the sub-light source module), and the centers of the three sub-light source modules are evenly distributed off-axis relative to the central axis of the lens body. The sub-incidence end faces corresponding to the light source modules are curved surfaces; when working, the center points of the three sub-light source modules are aligned with the centers of the curved surfaces corresponding to the sub-incident end faces, and the corresponding sub-curved surfaces adjust the off-axis of the part emitted by the sub-light source modules. The light is modulated into on-axis light or paraxial light of the axis of the sub-incident end face parallel to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com