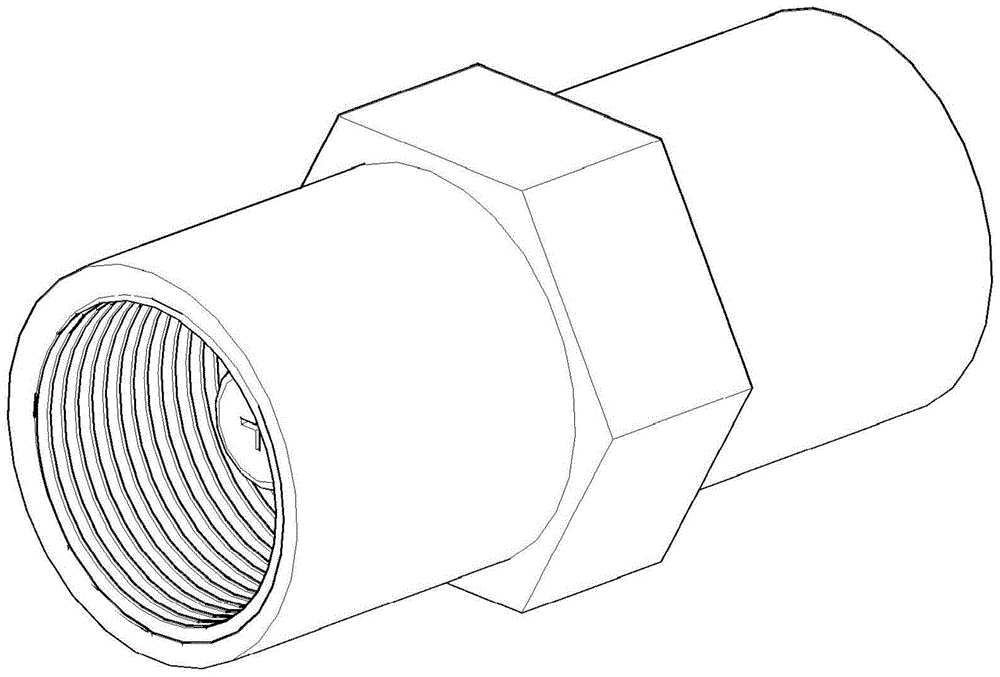

a joint

A piston head and piston rod technology, applied in the direction of pipes/pipe joints/pipe fittings, connections with fluid cut-off devices, passing components, etc., can solve problems such as easy to wet the surrounding environment and difficult adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

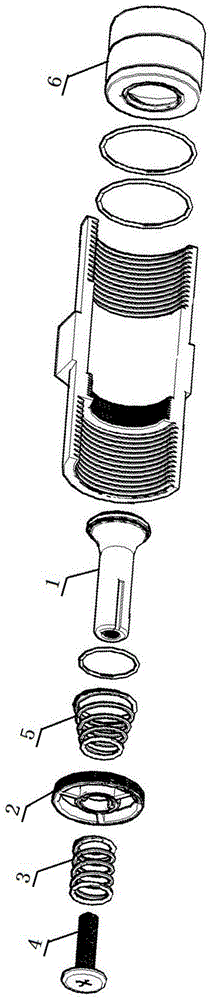

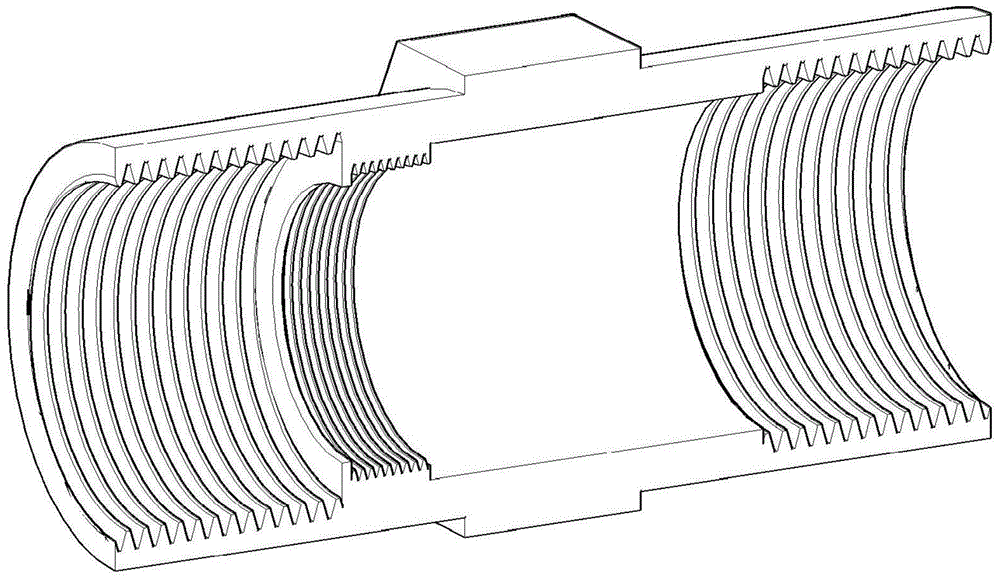

[0022] Such as Figure 1 to Figure 3 As shown, a joint is mainly composed of a body, a piston 1, a bracket 2, a prestressed spring 3 and a prestressed screw 4, and the piston includes a piston head and a piston rod. The direction of the piston head is sunken in the first adjusting hole, the adjusting hole is provided with an internal thread matching the external thread of the prestressing screw, and a second adjusting hole is provided on the wall of the piston head away from the piston rod.

[0023] The joint also includes a closing spring 5 and a regulating valve 6; the inner wall of the body is provided with an inwardly protruding boss coaxial with the body around the inner wall of the body, and a ring and the external thread of the outer wall of the bracket are arranged on the inner wall of the boss Matching internal thread, on the edge of the boss facing the water inlet end, a circle of flange protruding inward is provided to prevent the bracket from sliding out of the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com