Full-redundant erection system and design method thereof

A design method and fully redundant technology, applied in fluid pressure actuation system components, fluid pressure actuation system testing, mechanical equipment, etc., to achieve the effects of improved system reliability, small structural footprint, and reduced number of stand-alone products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

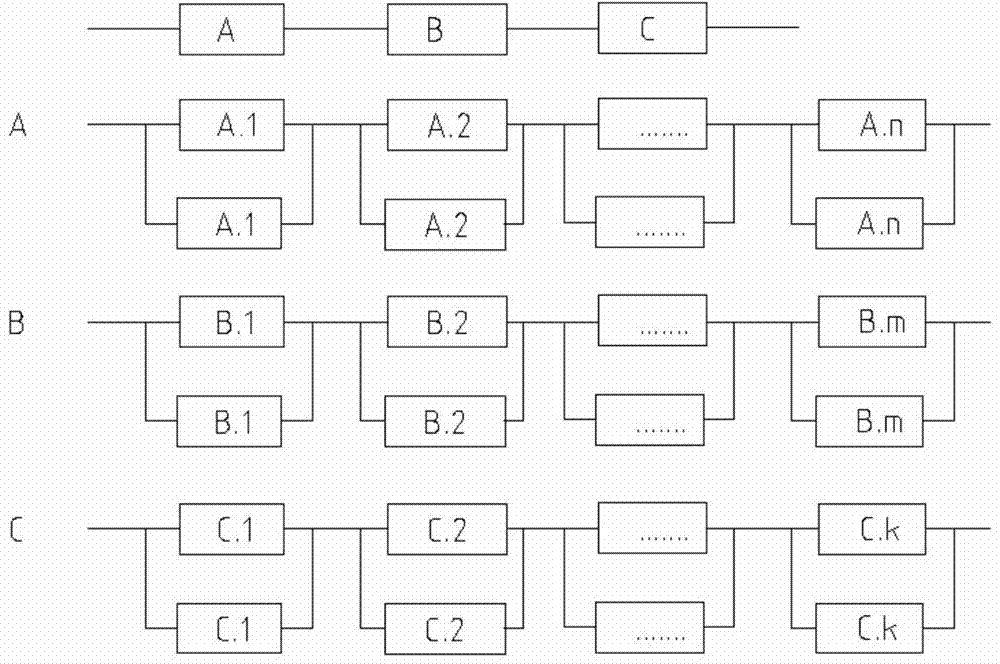

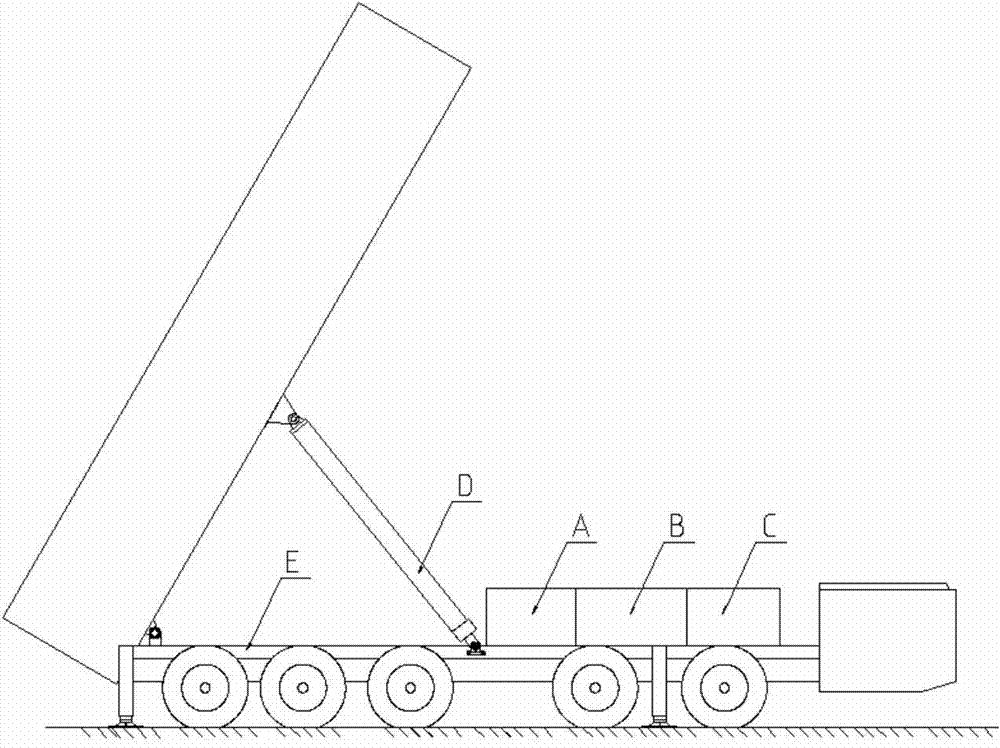

[0035] Such as figure 2 As shown, the fully redundant erecting system includes a hydraulic system A, a control system B, a power supply and distribution system C, an erecting actuator D, and an erecting load-bearing structure E. Among them, hydraulic system A includes equipment, control valves, pipelines, etc., control system B includes stand-alone machines, cables, software, etc., and power supply and distribution system C includes stand-alone machines, cables, software, etc.

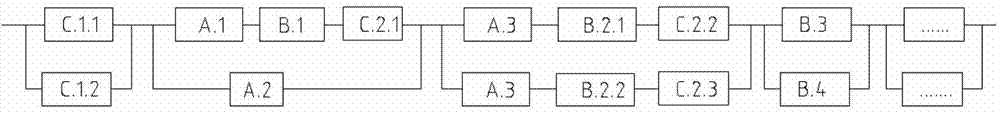

[0036] image 3 The meanings of the symbols in are as follows:

[0037] A.1, A.2...A.n—the first to nth equipment or valves of the hydraulic system and other stand-alone products.

[0038] B.1, B.2...B.m——the 1st to the mth stand-alone product, circuit or software of the control system.

[0039] B.1.1, B.1.2..., B.m.2——The 1st to mth single machines, lines, different circuits or different lines in the software of the control system.

[0040] C.1, C.2...C.k——the 1st to kth stand-alone products, lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com