An Improved Horizontal Continuous Annealing Furnace and a Method for Reducing Oxidation of Silicon Steel Strips

A continuous annealing furnace, silicon steel strip technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve problems such as poor sealing, affecting the surface quality and coating quality of silicon steel, and the surface color of steel strips after the furnace is black.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

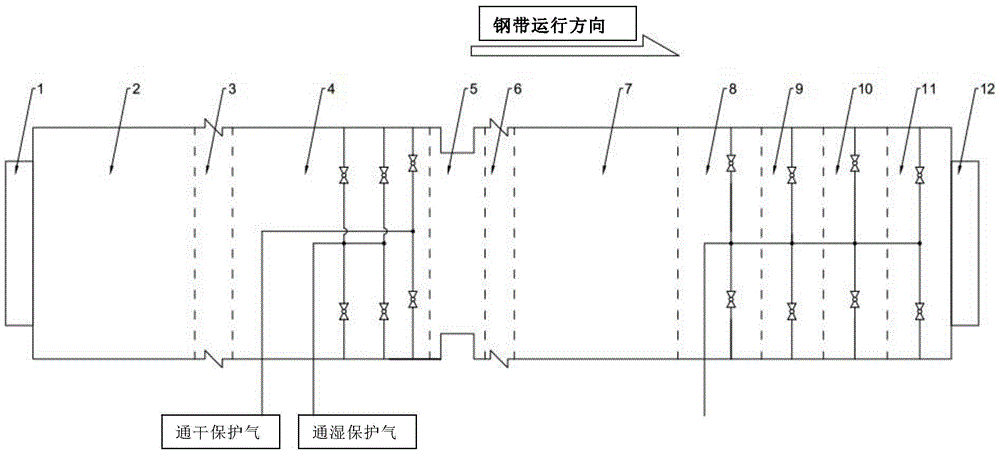

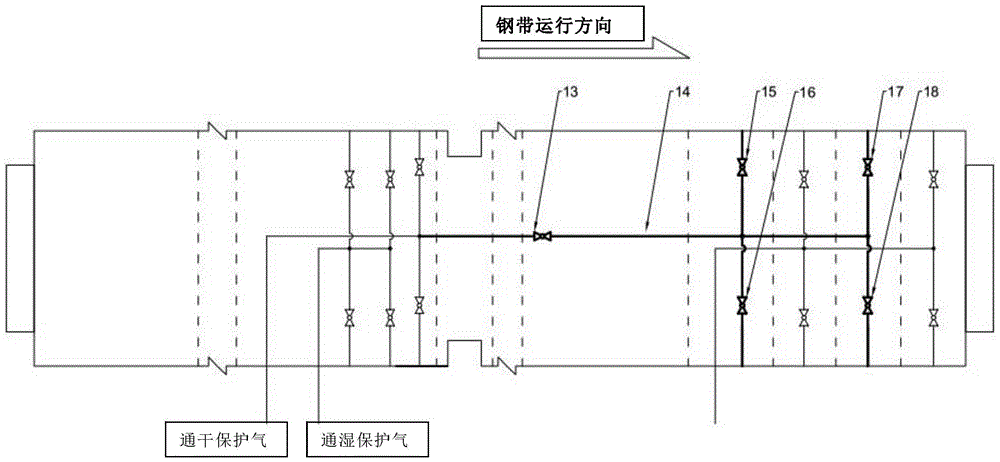

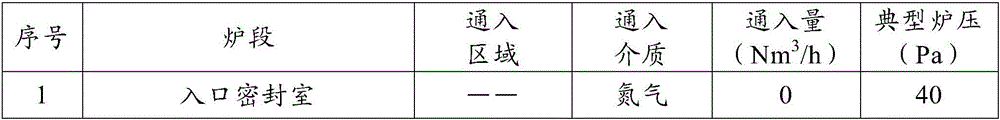

[0022] The type and amount of typical medium feeding in each furnace section of the improved horizontal continuous annealing furnace are shown in Table 1:

[0023] Table 1 Types and volumes of typical medium feeding in each furnace section

[0024]

[0025]

[0026] According to the above examples, when the oxygen content in the circulating gas injection cooling section is as high as 300ppm, the bright whiteness of the surface color of the steel strip out of the furnace still meets the requirements for the surface quality and coating quality of silicon steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com