Special efficient polyaluminum chloride for printing and dyeing wastewater, and preparation method thereof

A technology for polyaluminum chloride, printing and dyeing wastewater, applied in textile industry wastewater treatment, flocculation/sedimentation water/sewage treatment, etc. The effect of excellent COD removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

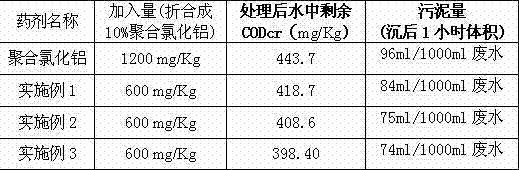

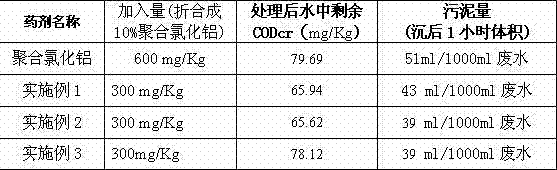

Examples

Embodiment 1

[0020] Embodiment 1: the high-efficiency polyaluminum chloride special for printing and dyeing wastewater of this example, its preparation method is:

[0021] Weigh 100 grams of hydrochloric acid with a concentration of 31%, add 22 grams of aluminum hydroxide, which contains Al 2 o 3 % is 64% (m / m), 100-120 0 C stirred and reacted for 2 hours to obtain 2 o 3 It is 11.5% (m / m) aluminum chloride liquid, add calcium aluminate powder 41 grams in above-mentioned aluminum chloride liquid, the Al of this calcium powder 2 o 3 The % is 50% (m / m), the total calcium is 32% (m / m), the water is 137 grams, and it is kept at 80-120 0 C was reacted for 1 hour to obtain 2 o 3 is 10.1% (m / m); the basicity is 85%; the density is 1.24 g / ml polyaluminum chloride; then add 196 grams of dilute hydrochloric acid to the above polyaluminum chloride liquid, and the concentration of the hydrochloric acid is 7.5% (m / m ), kept at 20-80 0 C was reacted for 1 hour to obtain polyaluminium chloride sp...

Embodiment 2

[0026] Embodiment 2: the high-efficiency polyaluminum chloride special for printing and dyeing wastewater of this example, its preparation method is:

[0027] Weigh 100 grams of electronic by-product hydrochloric acid with a concentration of 15%, and Al in this hydrochloric acid 2 o 3 % is 3%, the total acidity is 15%, heated to 50 0 C, add 16 grams of calcium aluminate powder, the calcium aluminate powder contains Al 2 o 3 % is 50% (m / m), and the total calcium content is 32% (m / m). Stir the reaction for 2 hours to obtain Al-containing 2 o 3 8.4% (m / m), salinity is 70%; polyaluminum chloride liquid with a density of 1.20 g / ml, add 13.5 g of hydrochloric acid to the above liquid, the concentration of the hydrochloric acid is 31%, and it is kept at 20-80 0 C was reacted for 2 hours to obtain 2 o 3 It is 7.5% (m / m); and the salinity is 55%, the density is 1.18 g / ml, and the special polyaluminium chloride for printing and dyeing wastewater.

[0028] The chemical reaction f...

Embodiment 3

[0031] Embodiment 3: the high-efficiency polyaluminum chloride special for printing and dyeing wastewater of this example, its preparation method is:

[0032] Weigh 100 grams of hydrochloric acid with a concentration of 31%, add 22 grams of aluminum hydroxide, which contains Al 2 o 3 % is 64% (m / m), 100-120 0 C stirred and reacted for 2 hours to obtain 2 o 3 It is 11.5% (m / m) aluminum chloride liquid, add calcium aluminate powder 30.5 grams in above-mentioned aluminum chloride liquid, the Al of this calcium powder 2 o 3 % is 50% (m / m), total calcium is 32% (m / m), water is 73 grams, and it is kept at 80-120 0 C was reacted for 1-2 hours to obtain 2 o 3 is 10.5% (m / m); the basicity is 75%; the density is 1.23 g / ml polyaluminum chloride; then add 33 grams of dilute phosphoric acid to the above polyaluminum chloride liquid, the phosphoric acid concentration is 40% (m / m ), kept at 20-80 0 C was reacted for 4 hours to obtain 2 o 3 9.1% (m / m); salinity 45%; density 1.22 g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com