Dry cargo container underframe part, dry cargo container and processing method thereof

A processing method and container technology, applied in the field of containers, can solve problems such as welding of front-end components and chassis components, and achieve the effects of saving material consumption and processing volume, securing firmness, and improving production efficiency and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

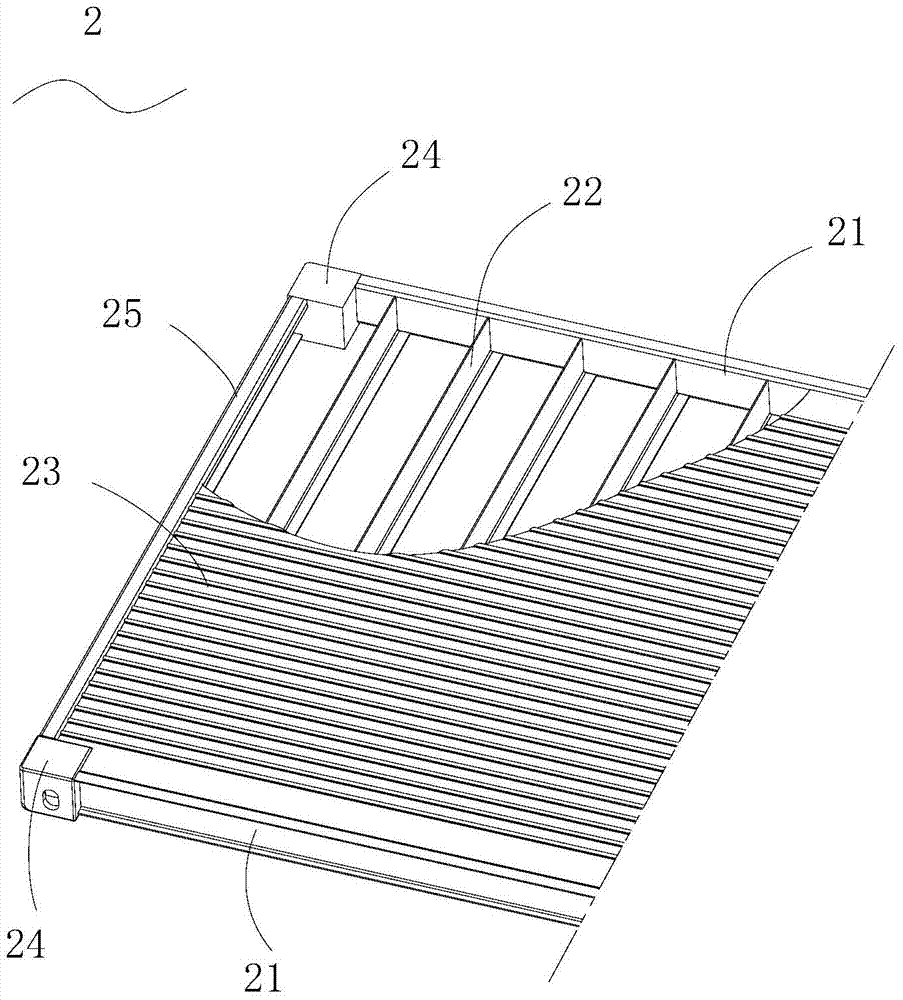

[0028] refer to image 3 , the present invention provides a dry cargo container underframe component 2, comprising two bottom side beams 21 extending longitudinally, a bottom beam 22 fixed between the two bottom side beams 21, a steel floor 23 positioned on the bottom beam 22, and a The two bottom corner fittings 24 at the same end of the two bottom side beams 21 and the end bottom cross beam 25 transversely connecting the two bottom corner fittings 24, the upper end surfaces of the two bottom corner fittings 24 and the end bottom cross beam 25 are used for connecting with the front end parts of the dry cargo container Assembly fixed.

[0029] The bottom frame part of the present invention is provided with bottom corner pieces and end bottom beams, which are use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com