Flexible invisible rack track system and method for track logistics vehicle

A track logistics and track technology, which is applied in the field of flexible invisible rack track system and flexible track system, can solve the problems of increased damage rate, increased cost, wear and tear of flexible track, and achieve improved durability and reliability, manufacturing and operating costs Low, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

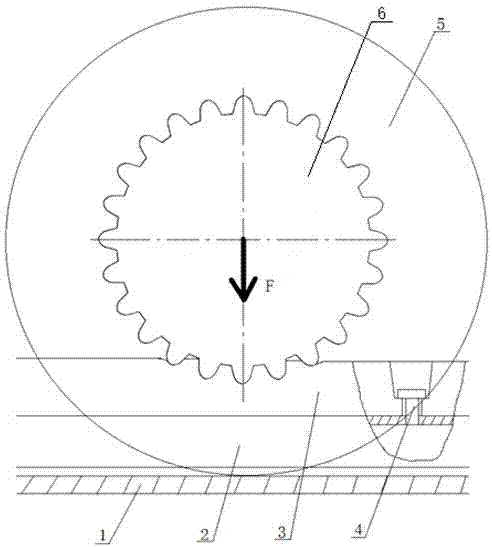

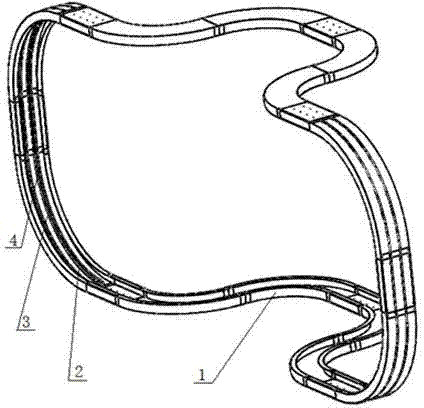

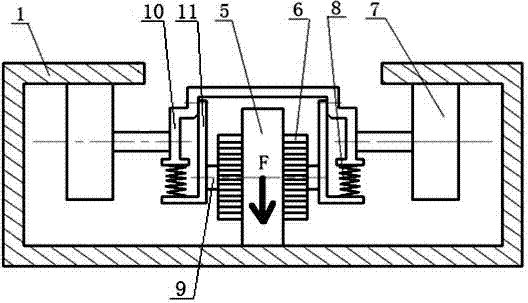

[0017] A flexible invisible rack rail system for rail logistics vehicles according to the present invention is characterized in that it consists of a space rail 1, a flexible rail bottom frame 2, a flexible rail 3, a flexible rail fixing member 4, and a rail car driving wheel 5 Formed with rail car drive gear 6. The flexible rail 3 is installed on the flexible rail bottom liner 2 along the track through the flexible rail fixing member 4 , and the flexible rail bottom liner 2 is fixed on the space rail 1 . The rail car drive gear 6 rotates coaxially with the rail car drive wheel 5, and the diameter of the latter is larger than the former. When running on a horizontal or small slope track, the rail car driving wheel 5 is used as the main driving part, relying on friction to drive the rail car forward; on a large slope, or even a vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com