A Physical Method for Improving the Crispness of Instant Black Fungus

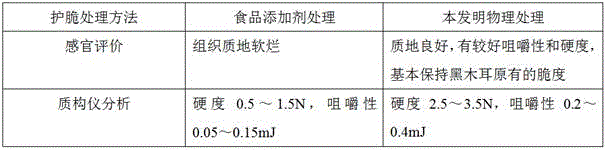

A physical method, the technology of black fungus, applied in the fields of food science, food preservation, application, etc., can solve problems such as the existence of more juice, differences in processing methods, and difficulty in vacuum packaging, so as to reduce the soaking time, the production process is simple, and the softness is avoided. rotten effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

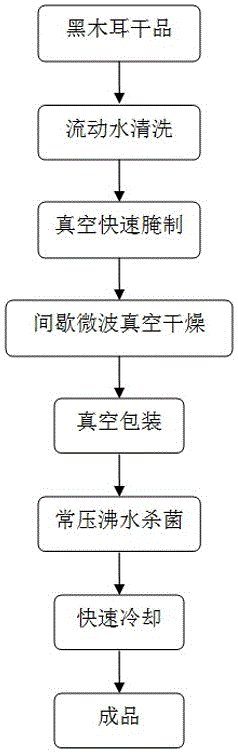

[0021] A physical method for improving the crispness of instant black fungus, the specific steps are as follows:

[0022] (1) Wash the dried black fungus with running water for 20 minutes to remove surface silt and other debris;

[0023] (2) Weigh 1000 g of purified water, 50 g of salt, 40 g of sugar, 3 g of monosodium glutamate, 10 g of soy sauce, 17 g of dried chili powder, 1.5 g of citric acid, and 1 g of disodium 5'-flavored nucleotide , 3 g of ethyl maltol, put into a vacuum rotary device and stir evenly;

[0024] (3) Marinate 100 g of washed black fungus and 1000 g of seasoning liquid in a vacuum rotary device for 20 minutes at a temperature of 40°C and a vacuum of -0.06MPa, and continuously rotate and stir during the marinating process;

[0025] (4) Drain the marinated black fungus and put them into a microwave vacuum drying device for intermittent microwave vacuum drying. During drying, heat them in microwave for 10 s and stop heating for 60 s. The control is at 75%,...

Embodiment 2

[0028] A physical method for improving the crispness of instant black fungus, the specific steps are as follows:

[0029] (1) Wash the dried black fungus with running water for 5 minutes to remove surface silt and other debris;

[0030] (2) Weigh 1000 g of purified water, 50 g of salt, 40 g of sugar, 3 g of monosodium glutamate, 10 g of soy sauce, 17 g of dried chili powder, 1.5 g of citric acid, and 1 g of disodium 5'-flavored nucleotide , 3 g of ethyl maltol, put into a vacuum rotary device and stir evenly;

[0031] (3) Marinate 100 g of washed black fungus and 1000 g of seasoning liquid in a vacuum rotary device for 10 minutes at a temperature of 50°C and a vacuum of -0.08MPa, and continuously rotate and stir during the marinating process;

[0032] (4) Drain the marinated black fungus and put them into a microwave vacuum drying device for intermittent microwave vacuum drying. During drying, heat them in microwave for 10 s and stop heating for 60 s. The control is at 65%, ...

Embodiment 3

[0035] A physical method for improving the crispness of instant black fungus, the specific steps are as follows:

[0036] (1) Wash the dried black fungus with running water for 10 minutes to remove surface silt and other debris;

[0037] (2) Weigh 1000 g of purified water, 50 g of salt, 40 g of sugar, 3 g of monosodium glutamate, 10 g of soy sauce, 17 g of dried chili powder, 1.5 g of citric acid, and 1 g of disodium 5'-flavored nucleotide , 3 g of ethyl maltol, put into a vacuum rotary device and stir evenly;

[0038] (3) Marinate 100 g of washed black fungus and 1,000 g of seasoning liquid in a vacuum rotary device for 30 minutes at a temperature of 30°C and a vacuum of -0.1MPaMPa. During the marinating process, rotate and stir continuously;

[0039] (4) Drain the marinated black fungus and put them into a microwave vacuum drying device for intermittent microwave vacuum drying. During drying, heat them in microwave for 10 s and stop heating for 60 s. The control is at 70%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com