Composite shielding device for driving circuit

A composite shielding and driving circuit technology, applied in the direction of magnetic field/electric field shielding, electrical components, etc., can solve the problems that high voltage interference cannot be isolated, electromagnetic interference cannot be completely shielded, etc., to increase creepage distance and electrical clearance, save space, meet Effect of Electrical Insulation Conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

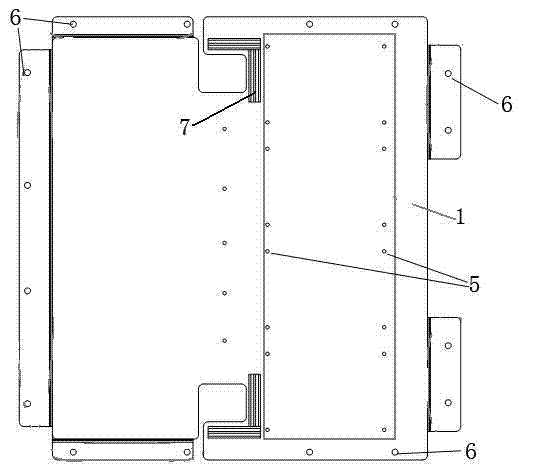

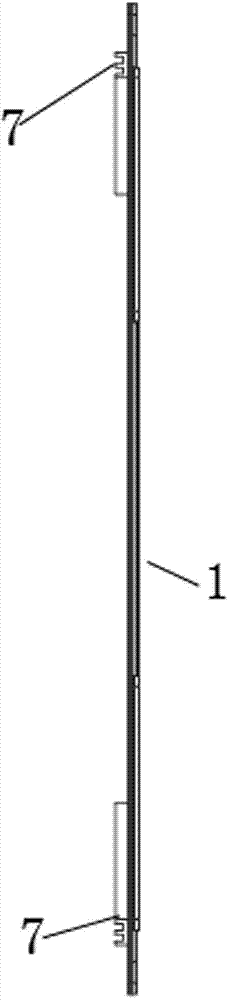

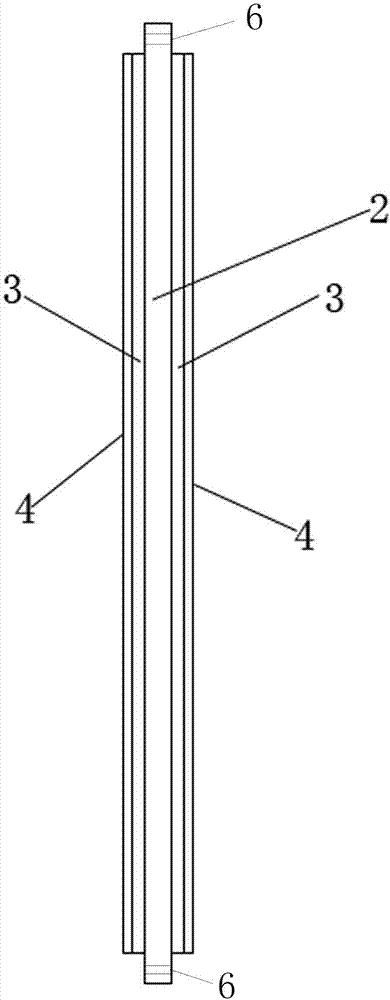

[0024] A driving circuit composite shielding device, including a composite shielding plate 1, the composite shielding plate 1 is made of 6061 aluminum alloy with a profile of 1~1.5mm (1.0mm, 1.1mm, 1.2mm, 1.3mm, 1.4mm, 1.5mm) thick metal layer 2, the thickness of the insulating material GPO-3 that is close to both sides of the metal layer 2 is 1~1.5mm (optional 1.0mm, 1.1mm, 1.2mm, 1.3mm, 1.4mm, 1.5mm) insulating layer 3 and an insulating protective film 4 compounded on the outer surface of the insulating layer 3; the outer surface of the composite shielding plate 1 is provided with a drive board installation hole 5; The extension is split with mounting pins 6 . figure 1 Each edge part of the middle composite shielding plate extends outwards, for example, the right side only partially extends outwards, while the left side extends outwards as a whole.

[0025] An insulating slot 7 is respectively fixed in the middle of the outer surface of the composite shielding plate 1 close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com