Cathode material of lithium sulphur battery, preparation method of cathode material, cathode of lithium sulphur battery and lithium sulphur battery

A technology for lithium-sulfur batteries and positive electrode materials, which is applied to battery electrodes, lithium batteries, and non-aqueous electrolyte battery electrodes. Achieve the effect of excellent electrochemical performance, low cost and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

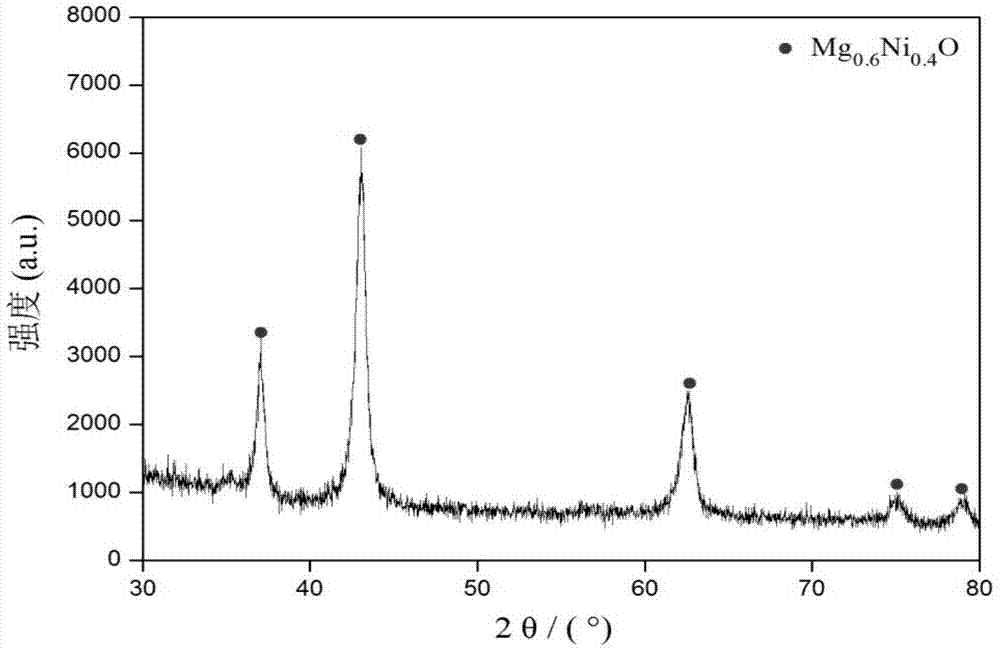

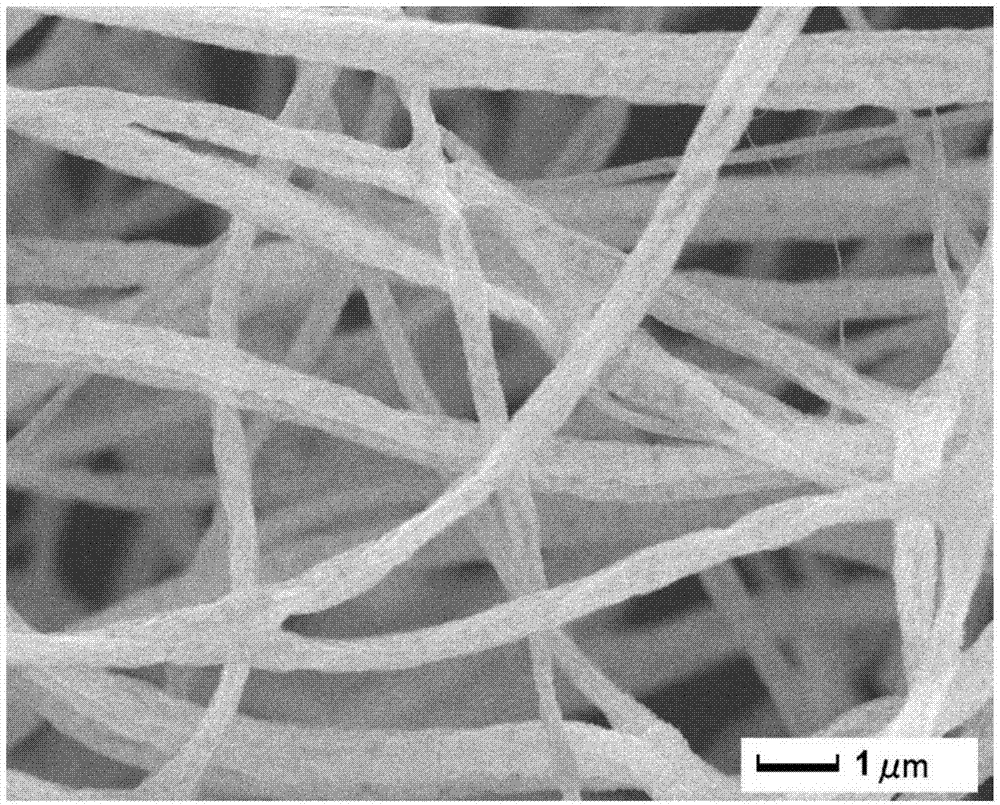

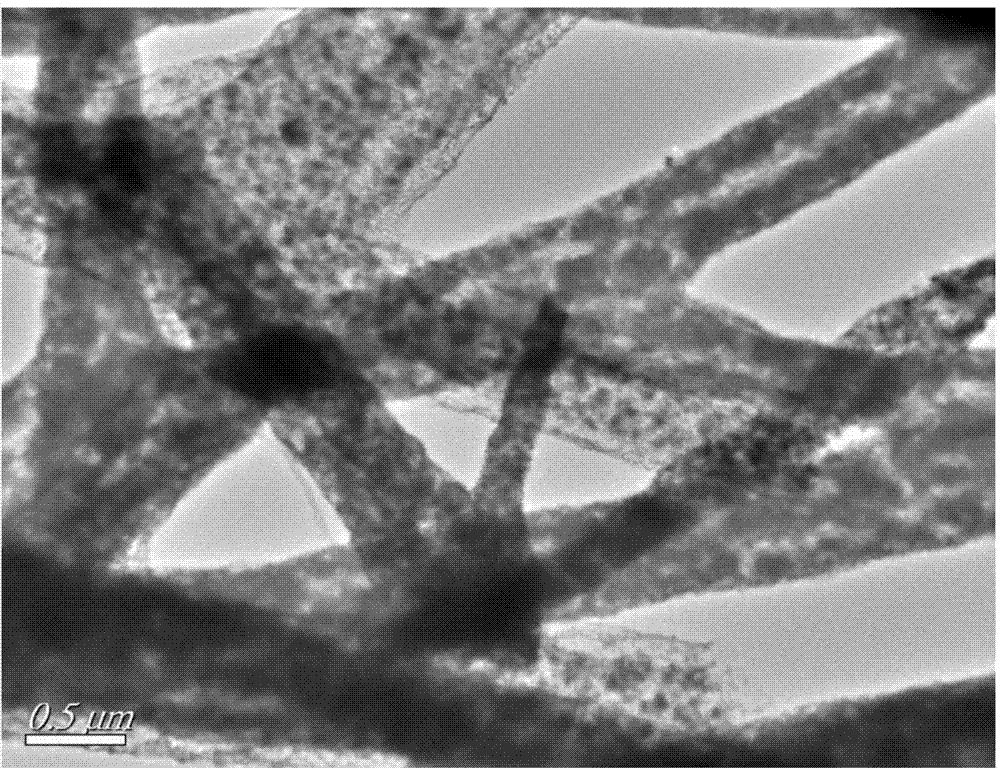

[0038] A cathode material for a lithium-sulfur battery of the present invention, which is made of metal oxide micro-nanotubes and sulfur composites, the diameter of the metal oxide micro-nanotubes is between 400-700nm, the length is 10μm-15μm, and the hollow part is connected with the micro-nanotubes. The diameter ratio of the tube is 0.1-0.2:1; the main component of the metal oxide micro-nano tube is Mg 0.6 Ni 0.4 O.

[0039] The above-mentioned preparation method of lithium-sulfur battery cathode material comprises the following steps:

[0040] 1) Add 3 g of polyacrylonitrile (average molecular weight of polyacrylonitrile is 150,000) into 20 ml of N,N-dimethylacetamide, fully dissolve at room temperature for 12 hours, and obtain solution A;

[0041] 2) Add 1.54g of magnesium nitrate and 1.16g of nickel nitrate to 10ml of N,N-dimethylacetamide, ultrasonically disperse for 30 minutes, and dissolve the metal salt in the N,N-dimethylacetamide solution to obtain a solution B; ...

Embodiment 2

[0050] A lithium-sulfur battery positive electrode material of the present invention is made of metal oxide micro-nanotubes and sulfur composites, the diameter of the composite metal oxide micro-nanotubes is 200nm, and the diameter ratio of the hollow part to the metal oxide micro-nanotubes is 0.3~0.6:1, the length is 20μm~50μm, the main component of composite metal oxide is Mg 0.8 Cu 0.2 O.

[0051] The above Mg 0.8 Cu 0.2 The preparation method of O nanotube, comprises the following steps:

[0052] (1) Add 3 g of polyacrylonitrile (the average molecular weight of polyacrylonitrile is 150,000) into 20 ml of N,N-dimethylacetamide, fully dissolve at room temperature for 12 hours, and obtain solution A;

[0053] (2) Add 2.05g of magnesium nitrate and 0.40g of copper acetate into 10ml of N,N-dimethylacetamide, ultrasonically disperse for 30 minutes, and dissolve the metal salt in the N,N-dimethylacetamide solution to obtain Solution B;

[0054] (3) Add solution B to solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com