Flexible display and manufacturing method thereof

A flexible display and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, static indicators, instruments, etc., can solve the problems of fragile brackets, reduced display deformability, and unfavorable high-end intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

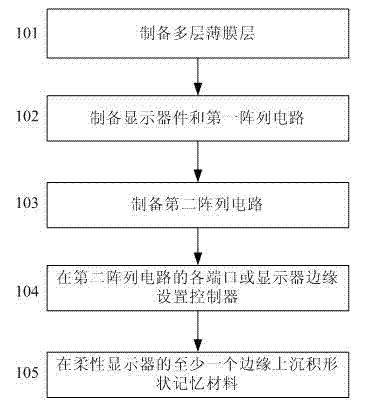

Method used

Image

Examples

Embodiment 1

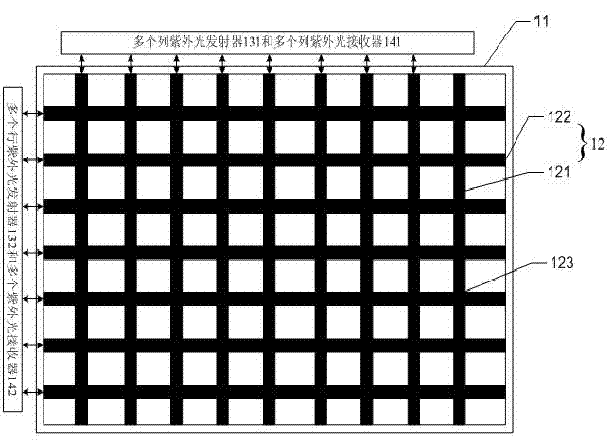

[0027] Such as figure 1 and figure 2 Shown is a schematic structural diagram of a flexible display. The flexible display in this embodiment is an active matrix organic light-emitting display (AMOLED), 11 is a flexible substrate, and a display device (not shown) and a first array are arranged on the flexible substrate 11. circuit (not shown). Preferably, the flexible substrate is an organic polymer PI, and of course, metal or glass can also be selected as the flexible substrate material as required. The display device includes active matrix organic light emitting diodes, pixel electrodes, common electrodes, and the like. The first array circuit is composed of data lines and gate lines distributed in a matrix, two adjacent data lines and gate lines enclose a rectangular area, and each rectangular area corresponds to a pixel. The flexible display also includes a front plate (not shown) positioned on top of the flexible display.

[0028] The second array circuit 12 is arrange...

Embodiment 2

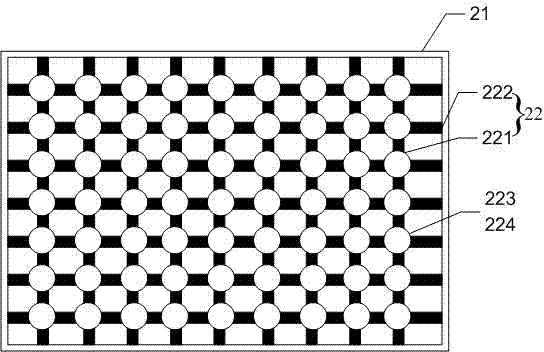

[0044] Such as Figure 4 and Figure 5 As shown, it is a schematic structural diagram of a flexible display. The flexible display in this embodiment is an active matrix organic light-emitting display (AMOLED), 21 is a flexible substrate, and a display device (not shown) and a first array circuit are arranged on the flexible substrate. (not shown). The flexible substrate is organic polymer PI, and of course metal or glass can also be selected as the flexible substrate material according to needs. The display device includes active matrix organic light emitting diodes, pixel electrodes, common electrodes, and the like. The first array circuit is composed of data lines and gate lines distributed in a matrix, two adjacent data lines and gate lines enclose a rectangular area, and each rectangular area corresponds to a pixel. The flexible display also includes a front plate (not shown) positioned on top of the flexible display.

[0045] A second array circuit 22 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com