Liquid crystal box and manufacturing method thereof and display device

A liquid crystal cell and liquid crystal layer technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve problems such as insufficient response time, large viscosity coefficient of liquid crystal, and jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

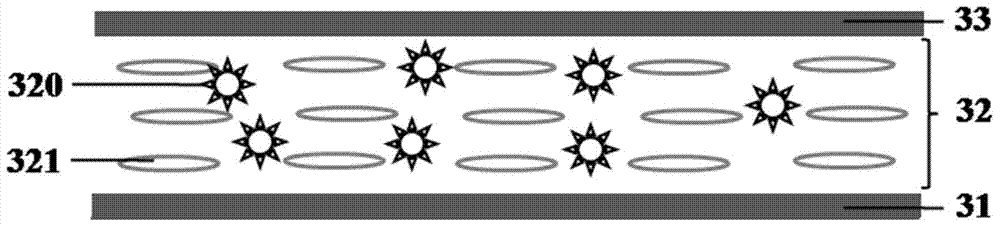

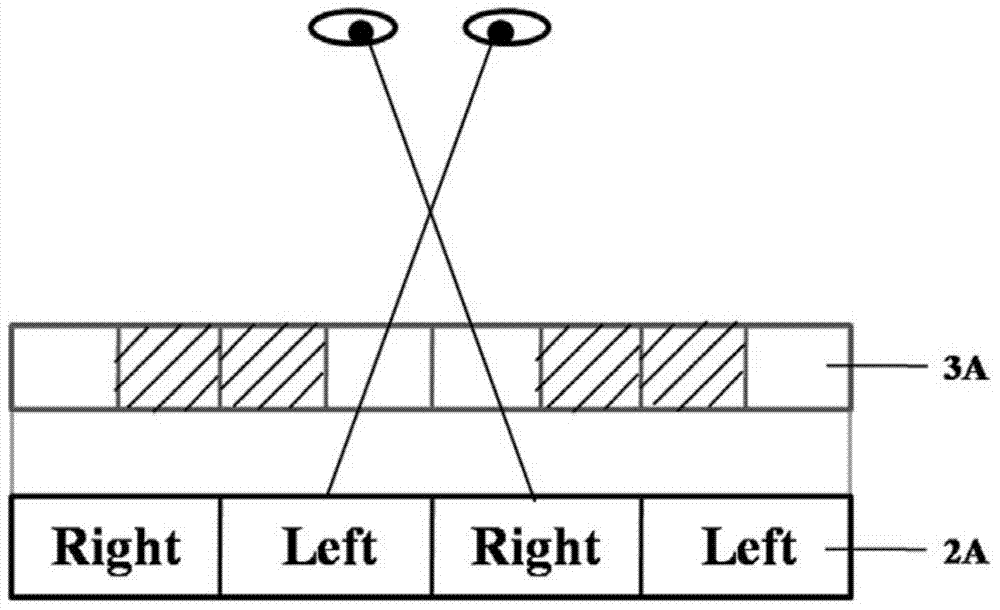

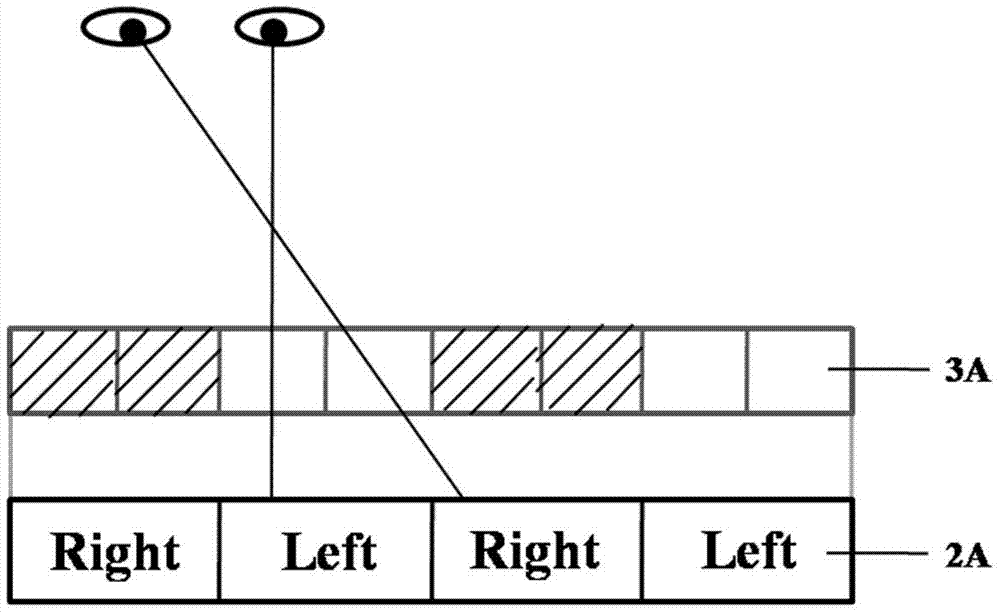

[0042] This embodiment provides a liquid crystal cell, comprising two substrates and a liquid crystal layer located between the two substrates, and switching between 2D and 3D display modes by controlling the deflection of the liquid crystal layer;

[0043] Wherein, ferric iron tetroxide nanoparticles with a mass ratio of 1% are added to the liquid crystal layer.

[0044] The liquid crystal layer in this embodiment adopts the liquid crystal grating method. When a voltage is applied on the two substrates, the ferroferric oxide nanoparticles convert electromagnetic energy into thermal energy, which increases the temperature at the applied voltage and reduces the viscosity coefficient of the liquid crystal. Accordingly, the response time of the liquid crystal is reduced, thereby improving the response speed of the 3D liquid crystal display device, avoiding the occurrence of crosstalk and image shaking, and improving the display effect of the naked-eye 3D liquid crystal display dev...

Embodiment 2

[0046] This embodiment provides a liquid crystal cell, comprising two substrates and a liquid crystal layer located between the two substrates, and switching between 2D and 3D display modes by controlling the deflection of the liquid crystal layer;

[0047] Wherein, ferric iron tetroxide nanoparticles with a mass ratio of 5% are added to the liquid crystal layer.

[0048] In this embodiment, the liquid crystal layer adopts the liquid crystal lens mode. When a voltage is applied, the ferroferric oxide nanoparticles convert electromagnetic energy into thermal energy, so that the temperature at the applied voltage rises, the viscosity coefficient of the liquid crystal decreases, and the corresponding response of the liquid crystal The time is reduced, thereby improving the response speed of the 3D liquid crystal display device, avoiding the occurrence of crosstalk and image shaking, and improving the display effect of the naked-eye 3D liquid crystal display device.

Embodiment 3

[0050] This embodiment provides a liquid crystal cell, comprising two substrates and a liquid crystal layer located between the two substrates, and switching between 2D and 3D display modes by controlling the deflection of the liquid crystal layer;

[0051] Wherein, ferric oxide nanoparticles modified with oleic acid with a mass ratio of 10% are added to the liquid crystal layer.

[0052] In this embodiment, the liquid crystal layer adopts the liquid crystal prism method. When a voltage is applied, the ferroferric oxide nanoparticles convert electromagnetic energy into heat energy, so that the temperature at the applied voltage rises, the viscosity coefficient of the liquid crystal decreases, and the corresponding response of the liquid crystal The time is reduced, thereby improving the response speed of the 3D liquid crystal display device, avoiding the occurrence of crosstalk and image shaking, and improving the display effect of the naked-eye 3D liquid crystal display device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com