Three-dimensional controllable dynamic compaction simulated centrifuge testing mechanical arm device

A centrifuge and manipulator technology, which is applied in the direction of applying repetitive force/pulse force to test the strength of materials, and can solve the problems affecting the reliability of water and soil pressure load tests and different stress levels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

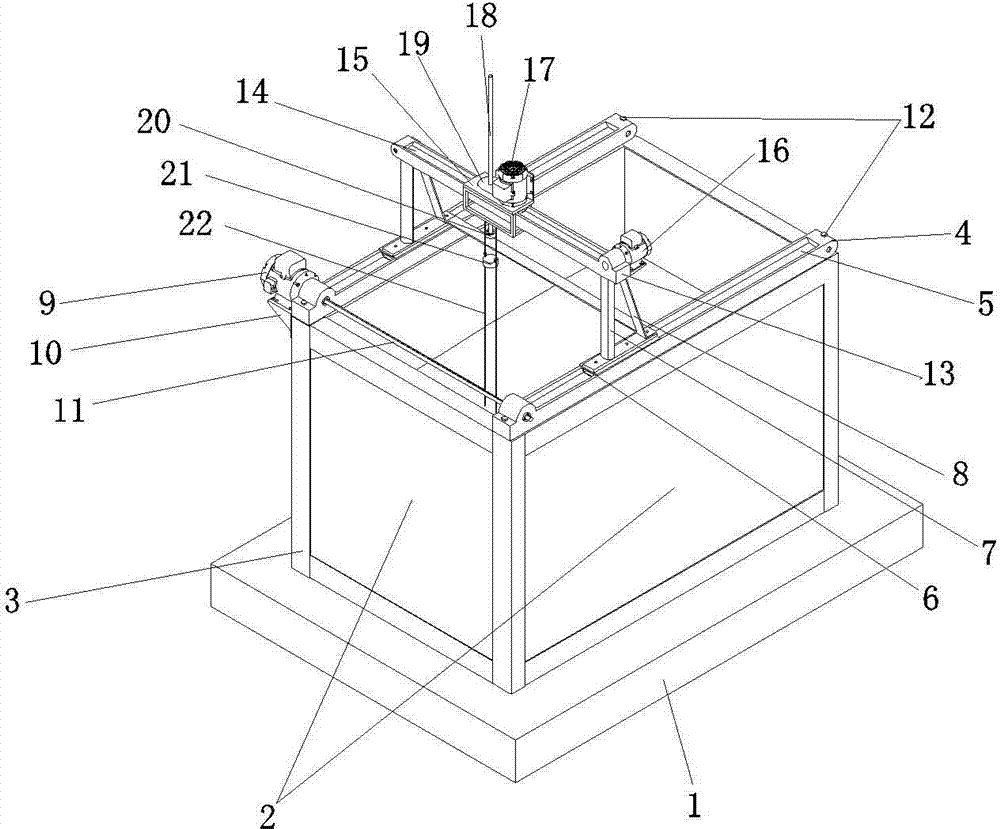

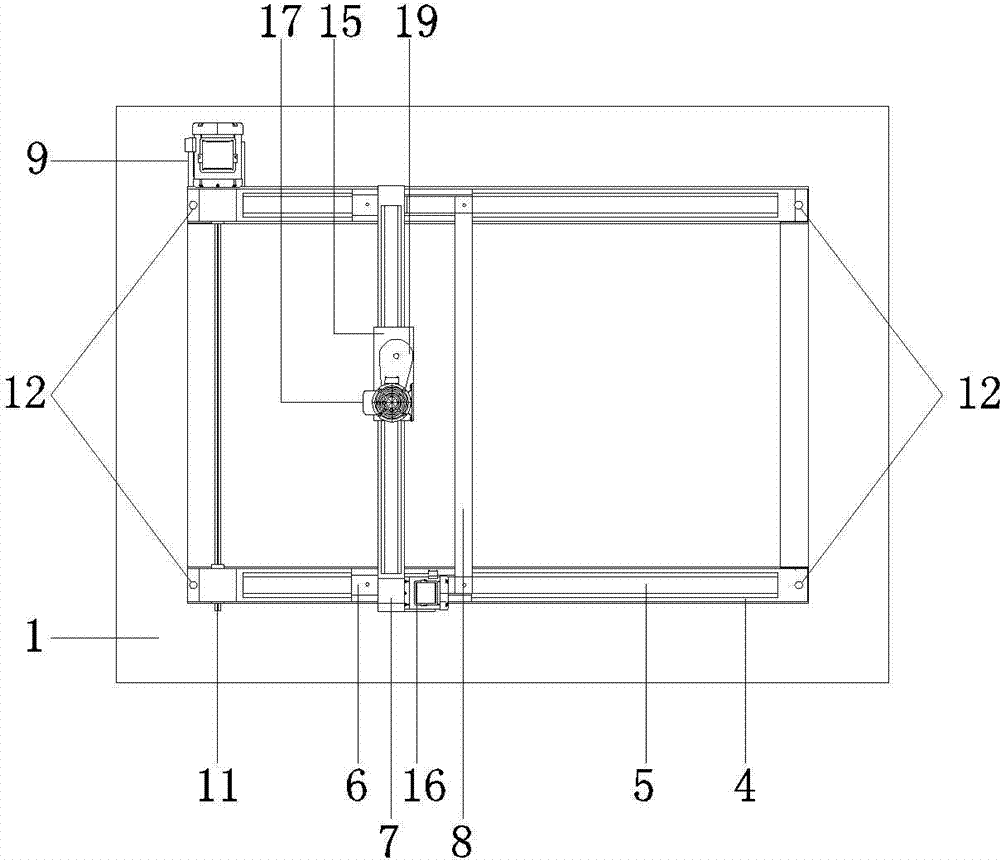

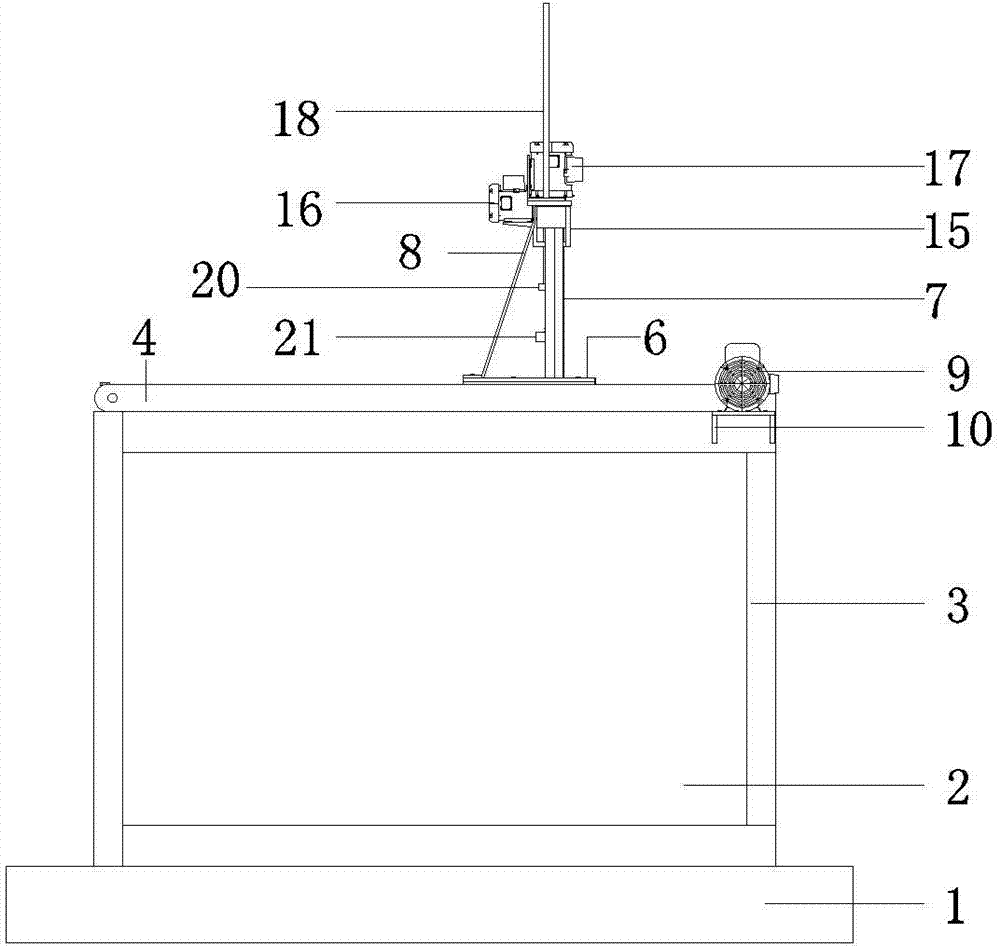

[0024] Such as Figure 1-Figure 7 As shown, the device consists of a base 1, a transparent glass observation window 2, a steel frame 3, a first rail 4, a first moving track 5, a slider 6, a bracket 7, a reinforcing bracket 8, a first motor 9, and a motor fixing plate 10. Transmission shaft 11 is fixed bolt 12, second track 13, second moving track 14, work platform 15, second motor 16, third motor 17, gearbox 18, displacement rod 19, electromagnetic relay 20, iron miniature rammer Hammer 21 and slide bar 22 form. Among them, the base 1 can be made of ordinary concrete blocks, and it is used as a platform for temporary storage when making soil samples in the model box. The base 1 needs to be level. The tamping manipulator is hoisted to the centrifuge basket for installation and fixation. The external dimensions of the model box are 900mm×700mm×700mm. In order to reduce deformation under high stress, the steel frame 3 is made of high carbon steel, and the glass used for the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com